Slurry composition for negative electrode of lithium ion secondary cell, negative electrode of lithium ion secondary cell, and lithium ion secondary cell

A secondary battery, lithium ion technology, used in secondary batteries, battery electrodes, lithium batteries, etc., can solve the problems of poor battery characteristics such as cycle characteristics and output characteristics, detachment of negative active materials, and volume expansion, etc. Good compatibility, good doping, and the effect of suppressing powder falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

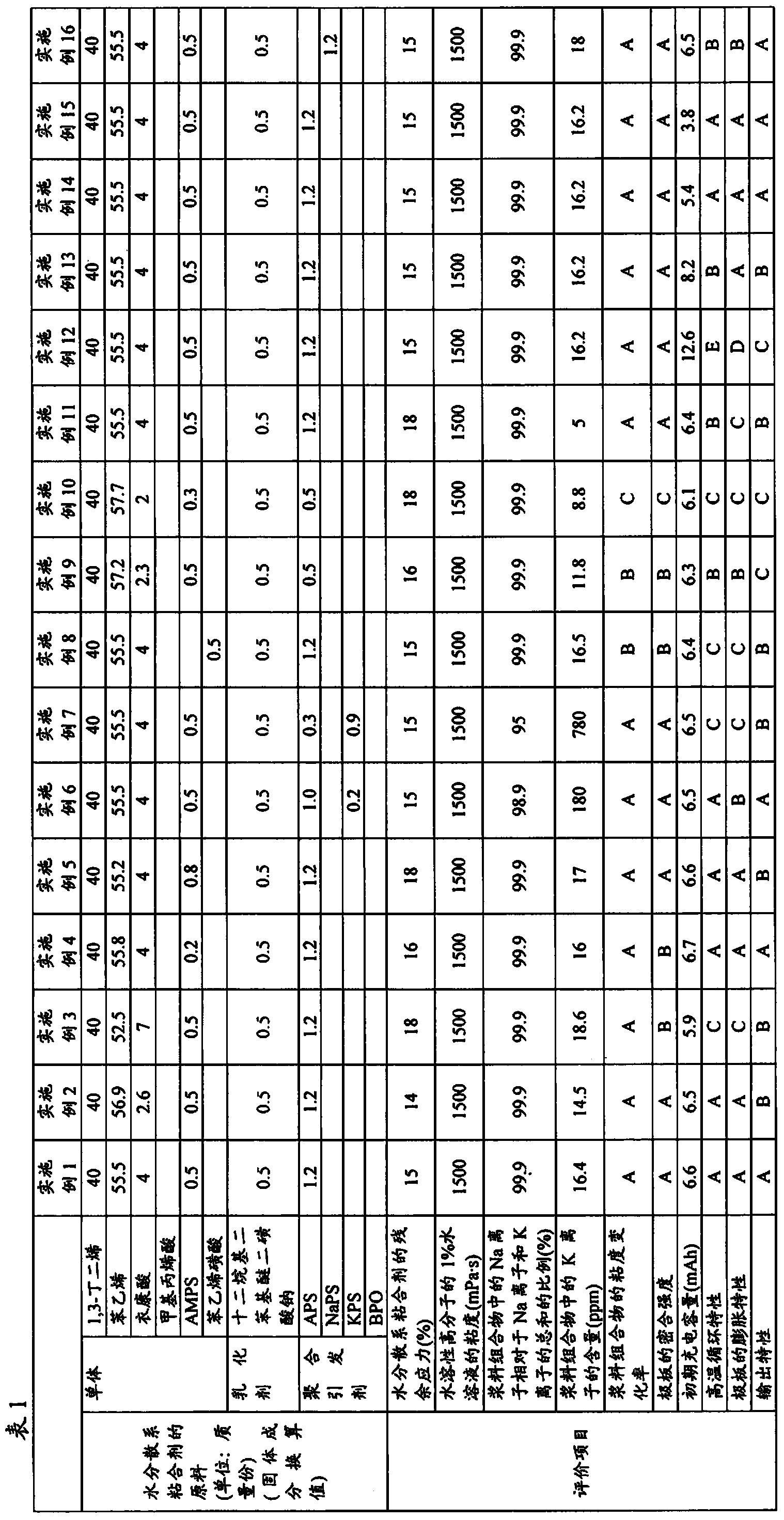

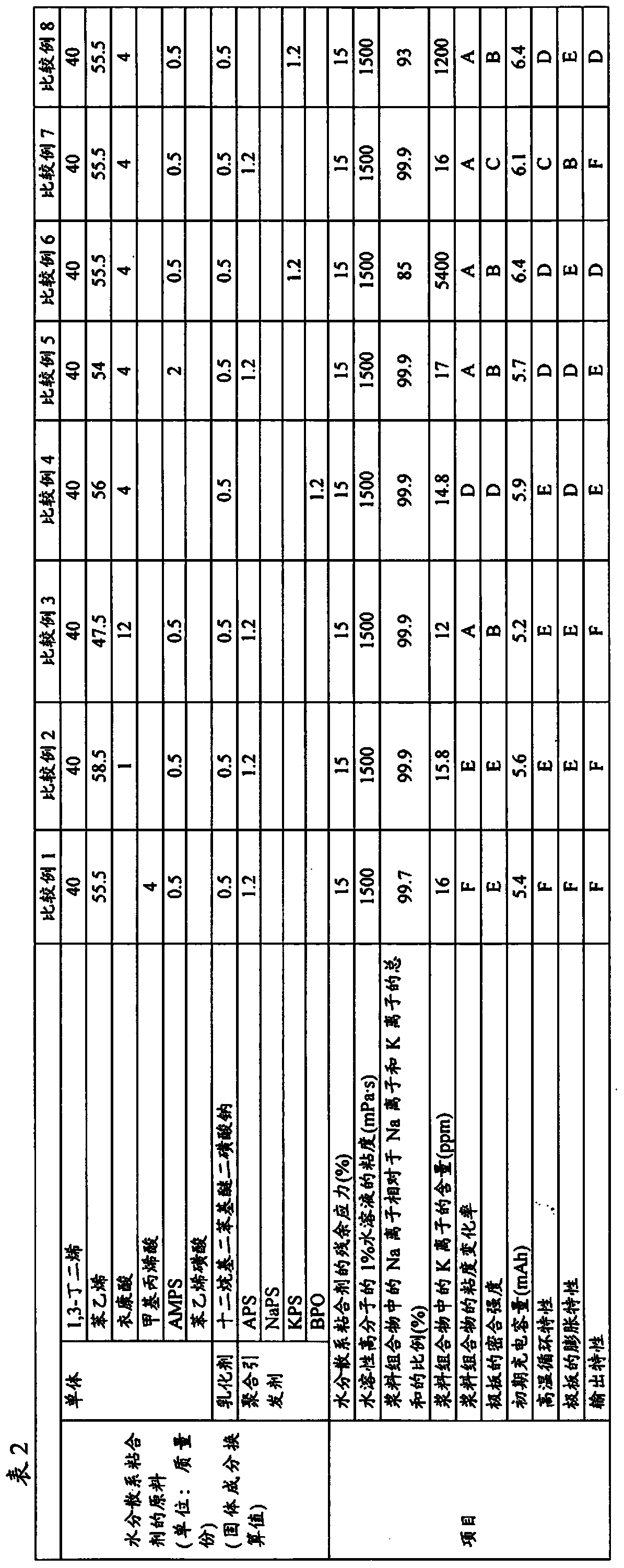

Embodiment 1

[0194] (Manufacture of water-dispersible adhesives)

[0195] 40 parts of ion-exchanged water, 0.25 parts of sodium dodecyl diphenyl ether disulfonate, 0.4 parts of tert-dodecyl mercaptan (TDM), 0.6 parts of ammonium persulfate, 55.5 parts of styrene, 1,3- Add 40 parts of butadiene, 4 parts of itaconic acid, and 0.5 part of acrylamide-2-methylpropanesulfonic acid into a pressure-resistant container equipped with a stirrer, and stir to obtain an emulsion of the monomer mixture. Next, 100 parts of ion-exchanged water and 0.25 parts of sodium dodecyl diphenyl ether disulfonate were added to a pressure-resistant polymerization vessel with a stirrer and stirred, the resulting mixture was heated to 75°C, and ion-exchanged After 10 parts of water and 0.6 parts of ammonium persulfate, the emulsion of the above monomer mixture was continuously added to this mixture over 240 minutes. After the addition of the emulsion of the above-mentioned monomer mixture is completed, the temperature ...

Embodiment 2

[0206] Except having used the following water-dispersible binder, the slurry composition for lithium ion secondary battery negative electrodes was obtained similarly to Example 1, and the lithium ion secondary battery was produced. Each evaluation result is shown in Table 1. Moreover, content of the sulfonic acid ion originating in the polymerization initiator in this slurry composition was 1.2 mass parts with respect to the total of 100 mass parts of monomers which comprise a water-dispersible adhesive. In addition, the total amount of free ions in this slurry composition was 14500 ppm with respect to 100% by mass of the slurry composition.

[0207] (Manufacture of water-dispersible adhesives)

[0208] 40 parts of ion-exchanged water, 0.25 parts of sodium dodecyl diphenyl ether disulfonate, 0.4 parts of tert-dodecyl mercaptan (TDM), 0.6 parts of ammonium persulfate, 56.9 parts of styrene, 1,3- 40 parts of butadiene, 2.6 parts of itaconic acid, and 0.5 parts of acrylamide-2-...

Embodiment 3

[0210] Except having used the following water-dispersible binder, the slurry composition for lithium ion secondary battery negative electrodes was obtained similarly to Example 1, and the lithium ion secondary battery was produced. Each evaluation result is shown in Table 1. Moreover, content of the sulfonate ion originating in the polymerization initiator in this slurry composition was 1.2 mass parts with respect to the total of 100 mass parts of monomers which comprise a water-dispersible adhesive. In addition, the total amount of free ions in this slurry composition was 18600 ppm with respect to 100% by mass of the slurry composition.

[0211] (Manufacture of water-dispersible adhesives)

[0212] 40 parts of ion-exchanged water, 0.25 parts of sodium dodecyl diphenyl ether disulfonate, 0.4 parts of tert-dodecyl mercaptan (TDM), 0.6 parts of ammonium persulfate, 52.5 parts of styrene, 1,3- Add 40 parts of butadiene, 7 parts of itaconic acid, and 0.5 parts of acrylamide-2-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com