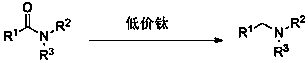

Method for reducing amide compounds

A technology for reducing amides and amides, which is applied in the preparation of organic compounds, the preparation of amino compounds, chemical instruments and methods, etc., can solve the problems of troublesome post-processing, high reaction cost, breakage, etc., and achieves low reagent cost, simple reaction operation, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

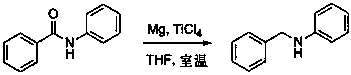

[0026] Example 1: Reduction of benzanilide

[0027]

[0028] Under the protection of Ar gas, Mg powder (10mmol) and THF (60mL) were added to the reaction flask, stirred in an ice bath, and TiCl was injected into the system. 4 (5 mmol), the reaction system was raised to room temperature and reacted for two hours to obtain a black suspension. The system was placed in an ice bath, and a solution of benzanilide (1 mmol) in THF (15 mL) was slowly added dropwise. After the dropwise addition, the mixture was raised to room temperature for reaction. After the reaction was completed, the reactant was placed in an ice bath, and saturated aqueous sodium bicarbonate solution was added thereto, and then 20% aqueous sodium hydroxide solution was added until the pH > 9. The reactant was filtered, the filtrate was extracted with dichloromethane, and the extract was concentrated to obtain a crude amine compound, which was then subjected to silica gel column chromatography to obtain N-ben...

Embodiment 2

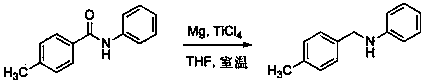

[0029] Example 2: Reduction of 4-methyl-N-phenylbenzamide

[0030]

[0031] The experimental operation was similar to that of Example 1, and N-(4-methylbenzyl)aniline was obtained as a colorless oil with a yield of 82%. 1 H NMR (400 MHz, CDCl 3 ) δ (ppm): 7.16 (d, J = 8.0 Hz, 2H), 7.03-7.10 (m, 4H), 6.61 (t, J = 8.0 Hz, 1H), 6.52 (d, J = 8.0 Hz, 2H), 4.15 (s, 2H), 3.77 (brs, 1H), 2.24 (s, 3H). 13 C NMR (100 MHz, CDCl 3 ) δ (ppm): 148.3, 136.9, 136.5, 129.4, 129.3, 127.6, 117.6, 112.9, 48.1, 21.2. HRMS (ESI): m / z calcd for C 14 h 16 N[M+H] + : 198.1283, found: 198.1287.

Embodiment 3

[0032] Example 3: Reduction of 4-methoxy-N-phenylbenzamide

[0033]

[0034] The experimental operation was similar to Example 1, and a colorless solid N-(4-methoxybenzyl)aniline was obtained with a yield of 86%. 1 H NMR (400 MHz, CDCl 3 ) δ (ppm): 7.28 (d, J = 8.0 Hz, 2 H), 7.16 (t, J = 8.0 Hz, 2H), 6.87 (d, J = 8.0 Hz, 2 H), 6.70 (t, J = 8.0 Hz, 1H), 6.63 (d, J = 8.0 Hz, 2H), 4.23 (s, 2H), 3.78 (s, 3H), 3.60 (brs, 1H). 13 C NMR (100 MHz, CDCl 3 ) δ (ppm): 158.9, 148.2, 131.4, 129.3, 128.9, 117.6, 114.1, 112.9, 55.3, 47.9. HRMS (ESI): m / z calcd for C 14 h 16 NO [M+H] + : 214.1232, found: 214.1238.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com