Biological refining lignin-compatibilized thermoplastic biodegradable polymer material and preparation method thereof

A polymer material and biorefinery technology, applied in the field of blended polymer materials, can solve problems such as reducing dependence on petroleum resources, achieve good mechanical properties, improve utilization, and prevent sticking effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

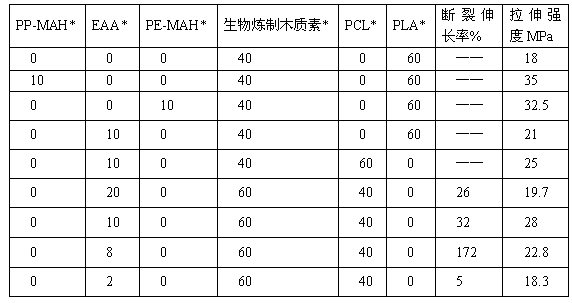

Examples

Embodiment 1

[0028] The raw materials are taken, and the raw material components are 30 parts by mass of thermoplastic polyester, 20 parts of biorefined lignin, and 10 parts of additives.

[0029] The thermoplastic polyester is polycaprolactone.

[0030] The auxiliary agent includes 3 parts by mass of compatibilizer ethylene-vinyl acetate copolymer, 3 parts by mass of plasticizer ethylene glycol, and 4 parts by mass of lubricant stearic acid.

[0031] A method for preparing biorefined lignin-enhanced thermoplastic degradable polymer materials: crushed and sieved biorefined lignin and polycaprolactone are mixed at a ratio of 20 / 80, and a co-rotating twin-screw compounding extruder is used Melt extrusion of the blended material was performed. Add the resin mixture, 5 parts of diphenylmethane diisocyanate, 5 parts of ethylene glycol, and 5 parts of natural paraffin into the silo of the twin-screw extruder, and force-feed the material. The heating temperature of the extruder is 130 ° C, 160°...

Embodiment 2

[0034] The raw materials are taken, and the raw material components are 80 parts by mass of thermoplastic polyester, 70 parts of biorefined lignin, and 30 parts of additives.

[0035] The thermoplastic polyester is polylactic acid.

[0036] The auxiliary agent includes 9 parts by mass of the compatibilizer ethylene-acrylate copolymer, 9 parts by mass of the plasticizer glycerin, and 12 parts by mass of the lubricant butyl stearate.

[0037]A method for preparing biorefined lignin-enhanced thermoplastic degradable polymer materials: crushed and sieved biorefined lignin and polycaprolactone are mixed at a ratio of 20 / 80, and a co-rotating twin-screw compounding extruder is used Melt extrusion of the blended material was performed. Add the resin mixture and 2 parts of diphenylmethane diisocyanate, 3 parts of maleic anhydride grafted polyethylene, 5 parts of ethylene glycol, and 5 parts of natural paraffin into the silo of the twin-screw extruder for forced feeding. The heating ...

Embodiment 3

[0040] The raw materials are taken, and the raw material components are 60 parts by mass of thermoplastic polyester, 45 parts of biorefined lignin, and 20 parts of additives.

[0041] The thermoplastic polyester is polyhydroxybutyrate.

[0042] The auxiliary agent includes 5 parts by mass of compatibilizer diphenylmethane diisocyanate, 5 parts by mass of plasticizer ethanolamine, and 10 parts by mass of lubricant oleamide.

[0043] A method for preparing a biorefined lignin-enhanced thermoplastic degradable polymer material: the pulverized and sieved biorefined lignin and polylactic acid are mixed at a ratio of 40 / 60, and co-rotating twin-screw compounding extruder is used for co-rotation. Melt extrusion of mixed materials. Add the resin mixture, 5 parts of diphenylmethane diisocyanate, 5 parts of ethylene glycol, and 5 parts of natural paraffin into the silo of the twin-screw extruder, force feeding, and the heating temperature of the extruder is 130 ° C, 160 ° C , 160°C, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com