Paper chip and preparation method thereof

A technology of paper chip and filter paper, applied in the field of paper chip and its preparation, can solve the problems of high toxicity of SU-8 photosensitive adhesive, which limits the development and application of paper chip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

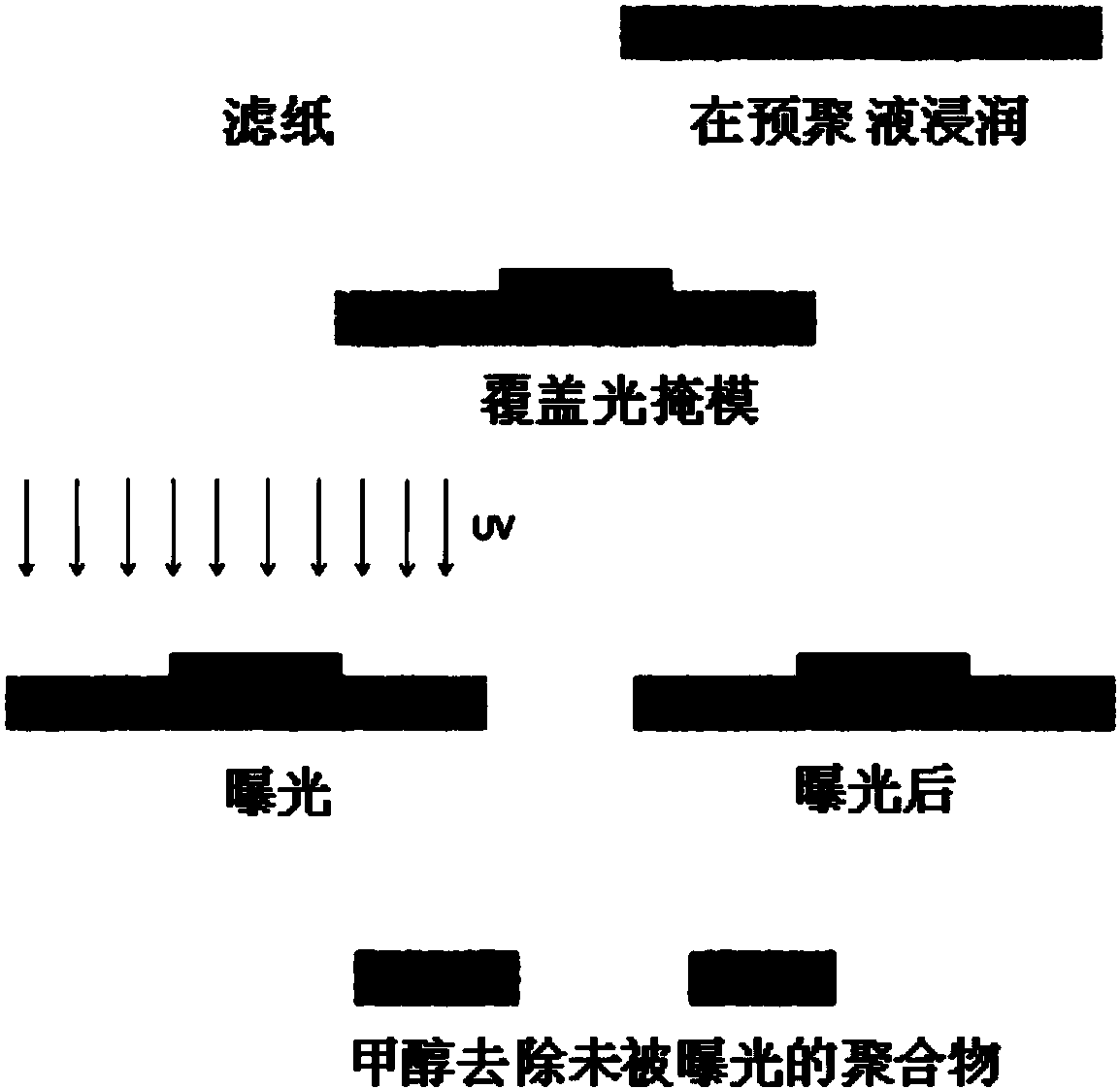

[0028] The invention provides a method for preparing a paper chip, comprising the following steps:

[0029] A) Soak the filter paper in the pre-polymerization solution, the pre-polymerization solution is a mixture of prepolymer and photoinitiator, the prepolymer contains acrylic acid functional group or methacrylic acid functional group, and the photoinitiator is Photoinitiators that can generate phenylcarbonyl radicals when excited by light;

[0030] B) Cover the surface of the infiltrated filter paper with a photolithography mask with a preset pattern, and then expose it to ultraviolet light;

[0031] C) Cleaning the exposed filter paper sheet with methanol to obtain a paper chip.

[0032] The invention applies photocatalytic free radical polymerization to the preparation of paper chips, replaces the traditional method of using SU-8 photosensitive adhesive to prepare paper chips, and establishes a novel and environment-friendly method for preparing paper chips.

[0033] f...

Embodiment 1

[0064] Using a filter paper sheet from Whatman chromatography paper, model number 3030-961, and a thickness of 0.34 mm, the filter paper sheet is soaked in a pre-polymerization liquid, and the pre-polymerization liquid is composed of polyethylene glycol diacrylate and 2-hydroxyl -2-Methyl-1-propyl-1-propanone is prepared by mixing at a volume ratio of 10:1.

[0065] Cover the surface of the wetted filter paper with a photolithographic mask with a dendritic pattern, and at the same time place a black paper under the filter paper, then place it under ultraviolet light for exposure, and the wavelength of the ultraviolet light is 365nm. The intensity of ultraviolet light is 15mJ / cm 2 , the exposure time is 3s.

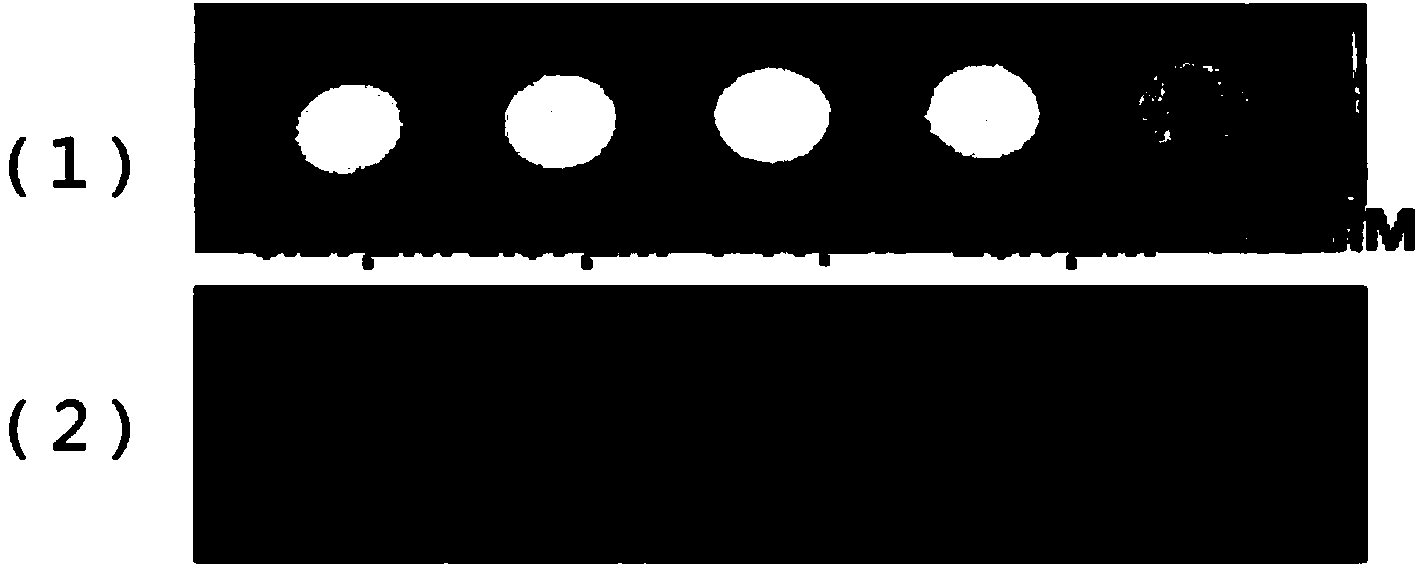

[0066] Immerse the exposed filter paper in the methanol solution for 20 minutes, remove the unexposed pre-polymerization liquid, and obtain the following image 3 The paper chip A shown, image 3 Optical photograph of paper chip A prepared for Example 1 of the present i...

Embodiment 2

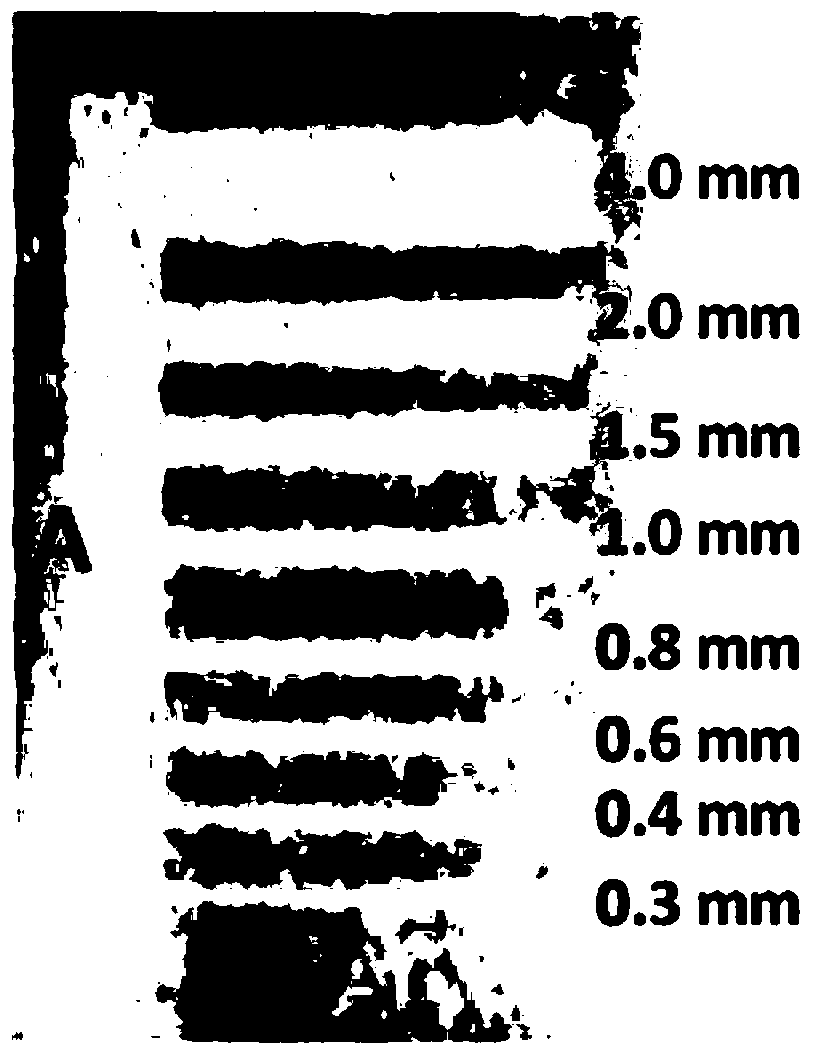

[0069] Adopt from Dongyang Industrial&Trading Co.,Ltd, model is 102, the filter paper sheet that thickness is 0.14mm, carries out the preparation of paper chip according to the step of embodiment 1, obtains as follows Figure 5 Paper chip B shown, Figure 5 Optical photograph of paper chip B prepared for Example 2 of the present invention. From Figure 5 As can be seen in , the paper chips B have different accuracies.

[0070] It can be known from Example 1 and Example 2 that the preparation method of the paper chip provided by the present invention does not depend on the selection of the thickness of the filter paper, and is not affected by the properties of the filter paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com