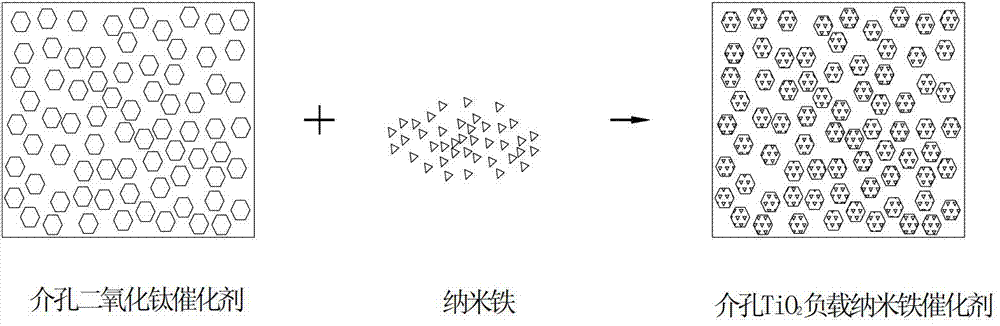

Preparation method of mesoporous TiO2 supported nano-iron catalyst

A catalyst and nano-iron technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor degradation effect, and achieve the goal of improving ability, inhibiting recombination, and uniform grain refinement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Mesoporous TiO of the present invention 2 The preparation method of loaded nano-iron catalyst, the method comprises the following steps:

[0035] (1) Preparation of butyl titanate hydrolysis buffer

[0036] Add 2.13ml of concentrated hydrochloric acid with a mass fraction of 36% to 38% into a 250mL volumetric flask filled with anhydrous ethanol solvent to prepare a 0.1mol / L hydrochloric acid ethanol solution as a butyl titanate hydrolysis buffer;

[0037] (2) Mesoporous TiO 2 Catalyst preparation

[0038] The reactants required to prepare mesoporous TiO2 include, EO 20 PO 70 EO 20 (P123), butyl titanate, absolute ethanol, distilled water, butyl titanate buffer solution;

[0039] EO 20 PO 70 EO 20 (P123) as a surfactant, mesoporous TiO was prepared by hydrothermal synthesis 2 , the volume ratio of the reactants is: butyl titanate: absolute ethanol: absolute ethanol + distilled water: butyl titanate hydrolysis buffer solution=10:10:5+2.1:1-5; the operation steps...

Embodiment 1

[0054] Example 1 Mesoporous TiO 2 Preparation of supported nano-iron catalyst

[0055] Step 1: Adding 2g of surfactant to mesoporous TiO 2 Catalyst preparation

[0056] The present invention adopts hydrothermal synthesis method, and uses EO 20 PO 70 EO 20 (P123) is a surfactant, and butyl titanate is a titanium source. Put 2g of surfactant and 10ml of absolute ethanol in a beaker, stir at room temperature to fully dissolve the surfactant. Then slowly add 10ml of butyl titanate under stirring, continue to stir for 30min and mix well, record it as X component. Put 2.1ml of distilled water, 5ml of absolute ethanol and 2ml of custom buffer solution of too much acid into a pear-shaped separating funnel and mix thoroughly, and record it as Y component. Put component X on a magnetic stirrer, turn on the magnetic stirrer to stir vigorously, add component Y to component X dropwise, and keep stirring for 1 h. The above solution was transferred to a stainless steel hydrothermal r...

Embodiment 2

[0062] Example 2 Mesoporous TiO 2 Preparation of supported nano-iron catalyst

[0063] Step 1: Same as Step 1 in Example 1

[0064] Step 2: Mesoporous TiO with 30% nano-Fe loading 2 Preparation of supported nano-iron catalyst

[0065] At a temperature of 15°C-35°C, 2.4 g of mesoporous TiO 2 Catalyst and 100ml0.2mol / LFeSO 4 ·7H 2 O aqueous solution is placed in a three-necked flask, sealed, and recorded as component A; component A is placed on a magnetic stirrer, nitrogen protection is passed into the three-necked flask, and component A is ultrasonically dispersed for 10 minutes, and magnetic stirring is turned on to make the component A Part A and mix well.

[0066] Prepare 100ml0.4mol / L NaBH 4 solution, and adjust the pH to 9-10 with NaOH to make weakly alkaline NaBH 4 Solution, denoted as B component;

[0067] Add 50ml of absolute ethanol to the above component A, stir evenly, and then under the protection of nitrogen atmosphere, add the newly prepared component B dro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com