Method for extracting Indian epimeredi herb dilactone from Indian epimeredi herb leaves

A technology for parsnip and dilactone is applied in the field of separation and preparation of parsnip dilactone, which can solve the problems such as no patent report on the preparation method of high-content parsnip dilactone, and achieves short preparation period, short time-consuming, and easy preparation. large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

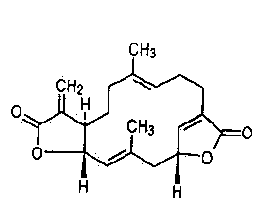

Image

Examples

Embodiment 1

[0026] Take dry parsnip leaves, crush them, control the particle size to 40 mesh, weigh 200g, add 15 times of 80% ethanol solution, and extract by ultra-high pressure method, the extraction pressure is 400MPa, the temperature is 35°C, and the holding time is 5min , repeat boosting and depressurization twice, combine the extracts, concentrate under reduced pressure, and perform chromatographic column chromatography. The chromatographic column uses neutral magnesium oxide as the filler, the particle size is 100 mesh, the column pressure is 5bar, and the column diameter-to-height ratio is 1 :10, petroleum ether-ethyl acetate 12:1, 5:1, 1:1 gradient elution, collect the target eluent, concentrate and dry to obtain the crude extract; use high-speed countercurrent chromatography to separate and purify the windproof in the crude extract Oxydilide, with a volume ratio of 5:7:5:3 n-hexane-ethyl acetate-methanol-water as a two-phase solvent system, the upper phase is filled with a high-s...

Embodiment 2

[0028] Take dry parsnip leaves, crush them, control the particle size to 40 mesh, weigh 500g, add 12 times of 90% ethanol solution, and use the ultra-high pressure method to extract, the extraction pressure is 300MPa, the temperature is 45°C, and the holding time is 10min , repeat boosting and depressurization twice, combine the extracts, concentrate under reduced pressure, and perform chromatographic column chromatography. The chromatographic column is filled with neutral magnesium oxide, the particle size is 100 mesh, the column pressure is 6bar, and the column diameter-to-height ratio is 1 :10, petroleum ether-ethyl acetate 12:1, 5:1, 1:1 gradient elution, collect the target eluent, concentrate and dry to obtain the crude extract; use high-speed countercurrent chromatography to separate and purify the windproof in the crude extract Oxydilide, with a volume ratio of 5:7:5:3 n-hexane-ethyl acetate-methanol-water as a two-phase solvent system, the upper phase is filled with a h...

Embodiment 3

[0030] Take dried parsnip leaves, crush them, control the particle size to 40 mesh, weigh 500g, add 15 times of 90% ethanol solution, and extract by ultra-high pressure method, the extraction pressure is 400MPa, the temperature is 40°C, and the holding time is 8min , repeat boosting and depressurization 3 times, combine the extracts, concentrate under reduced pressure, and perform chromatographic column chromatography. The chromatographic column uses neutral magnesium oxide as the filler, the particle size is 100 mesh, the column pressure is 7.5bar, and the column diameter-to-height ratio is 1:12, petroleum ether-ethyl acetate 11:1, 4:1, 1:1 gradient elution, collect the target eluent, concentrate and dry to obtain the crude extract; use high-speed countercurrent chromatography to separate and purify the Parsnip dilactone, with a volume ratio of 5:7:5:3 n-hexane-ethyl acetate-methanol-water as a two-phase solvent system, the upper phase is filled with a high-speed countercurren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com