Hydrophilicity and hydrophobicity adjustable nano SiO2 powder

A nano and powder technology, applied in the treatment of dyed organosilicon compounds, dyed polymer organic compounds, fibrous fillers, etc., can solve the problems of unsuitable industrial applications, expensive raw materials, and complex synthesis processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Mix and stir 16g deionized water, 64g ethanol, and 3.2g ammonia water, add 6.4g tetraethyl orthosilicate when it rises to 30°C, add 3.2g vinyltriethoxysilane after 5 minutes, continue stirring for 20 minutes, and then Centrifugal separation, washing and drying to obtain vinyl SiO 2 particles;

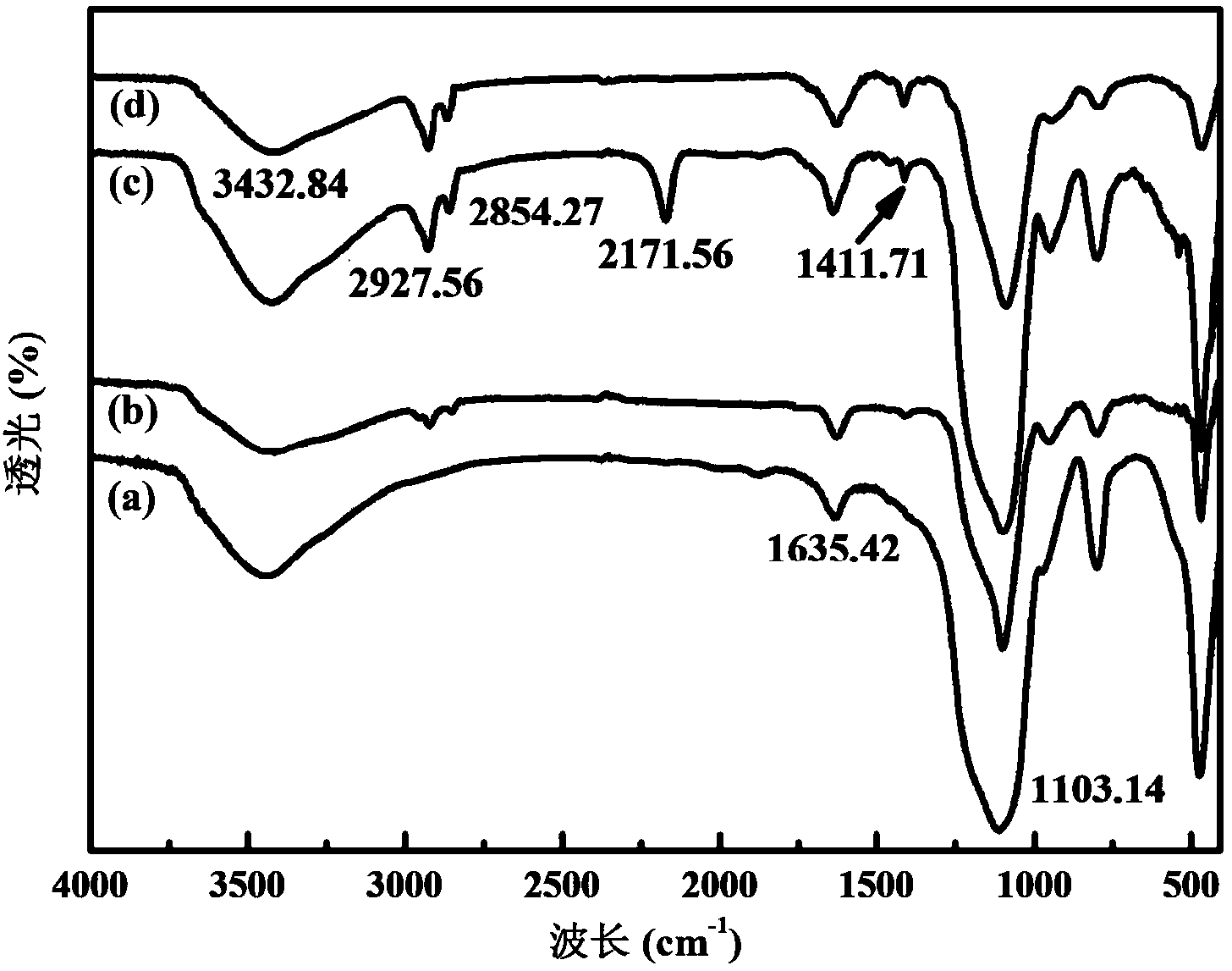

[0032] Take 1g of vinyl SiO 2 , ultrasonically dispersed in 100mL cyclohexanone, added 0.5g hydrogen-containing silicone oil (hydrogen content 1%), 0.3g chloroplatinic acid, refluxed and stirred at 150°C for 6 hours, then added 1g allyl polyether (molecular weight 300), Continue to reflux and stir for 6 hours, centrifuge, wash and dry to obtain modified nano-SiO 2 Powder. The prepared modified nano-SiO 2 The infrared spectrum of the powder is shown in figure 1 As shown, it can be seen from the figure that nano-SiO 2 The surface is grafted with hydrophobic hydrogen-containing silicone oil and hydrophilic allyl polyether at the same time.

[0033] Take 0.2g modified nano-SiO...

Embodiment 2

[0036]Mix and stir 16g deionized water, 64g ethanol, and 4.8g ammonia water, add 6.4g tetraethyl orthosilicate when it rises to 40°C, add 4.8g vinyltriethoxysilane after 5 minutes, continue stirring for 25 minutes, and then Centrifugal separation, washing and drying to obtain vinyl SiO 2 particles;

[0037] Take 1g of vinyl SiO 2 , ultrasonically dispersed in 150mL 1,4-dioxane, added 0.8g hydrogen-containing silicone oil (hydrogen content 1.56%), 0.4g chloroplatinic acid, refluxed and stirred at 100°C for 6 hours, then added 8g allyl polyether ( Molecular weight 300), continue to reflux and stir for 6 hours, centrifuge, wash and dry to obtain modified nano-SiO 2 Powder.

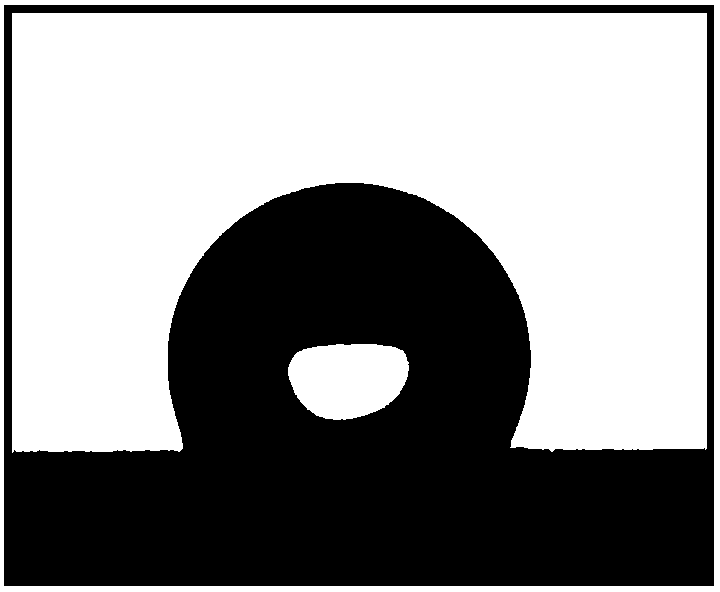

[0038] Take 0.2g modified nano-SiO 2 Powder, 10g ethanol, ultrasound 20min to obtain dispersion, pull the coating on a glass plate, bake at 100°C for 2h, test its contact angle to be 124°, as image 3 .

[0039] Take 0.2g modified nano-SiO 2 Powder, 20g organic solvent (respectively n-hexane, toluene, ...

Embodiment 3

[0041] Mix and stir 16g deionized water, 72g ethanol, and 4.8g ammonia water, add 7.2g tetraethyl orthosilicate when it rises to 50°C, add 4.8g vinyltriethoxysilane after 10 minutes, continue stirring for 25 minutes, and then Centrifugal separation, washing and drying to obtain vinyl SiO 2 particles;

[0042] Take 1g of vinyl SiO 2 , ultrasonically dispersed in 100mL N,N-dimethylformamide, added 1g hydrogen-containing silicone oil (hydrogen content 1.56%), 0.4g Karstedt catalyst, refluxed and stirred at 150°C for 8 hours, then added 1g allyl polyether (molecular weight 500 ), continue to reflux and stir for 6 hours, centrifuge, wash and dry to obtain modified nano-SiO 2 Powder.

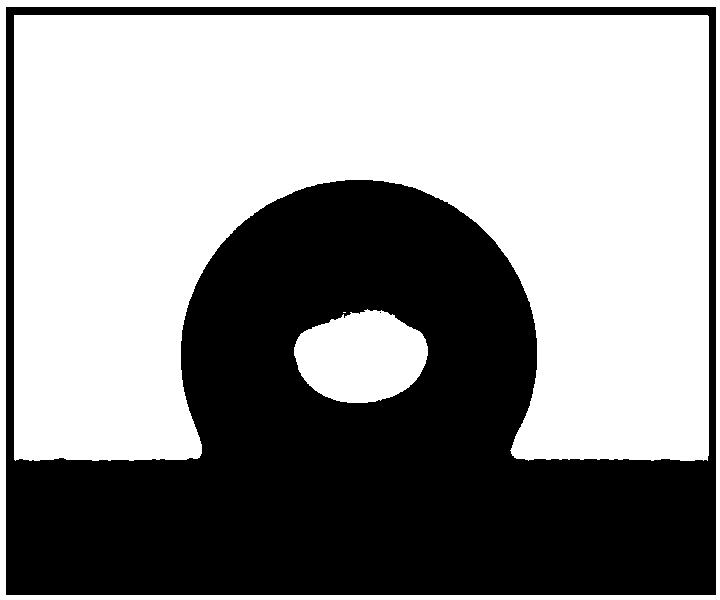

[0043] Take 0.2g modified nano-SiO 2 Powder, 10g ethanol, ultrasonic 20min to obtain dispersion liquid, pull coating film on a glass sheet, bake at 100°C for 2h, test its contact angle to be 139°, as Figure 4 .

[0044] Take 0.2g modified nano-SiO 2 Powder, 20g of organic solvents (n-hexane, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com