Enzyme-macromolecule conjugate and preparing method and application thereof

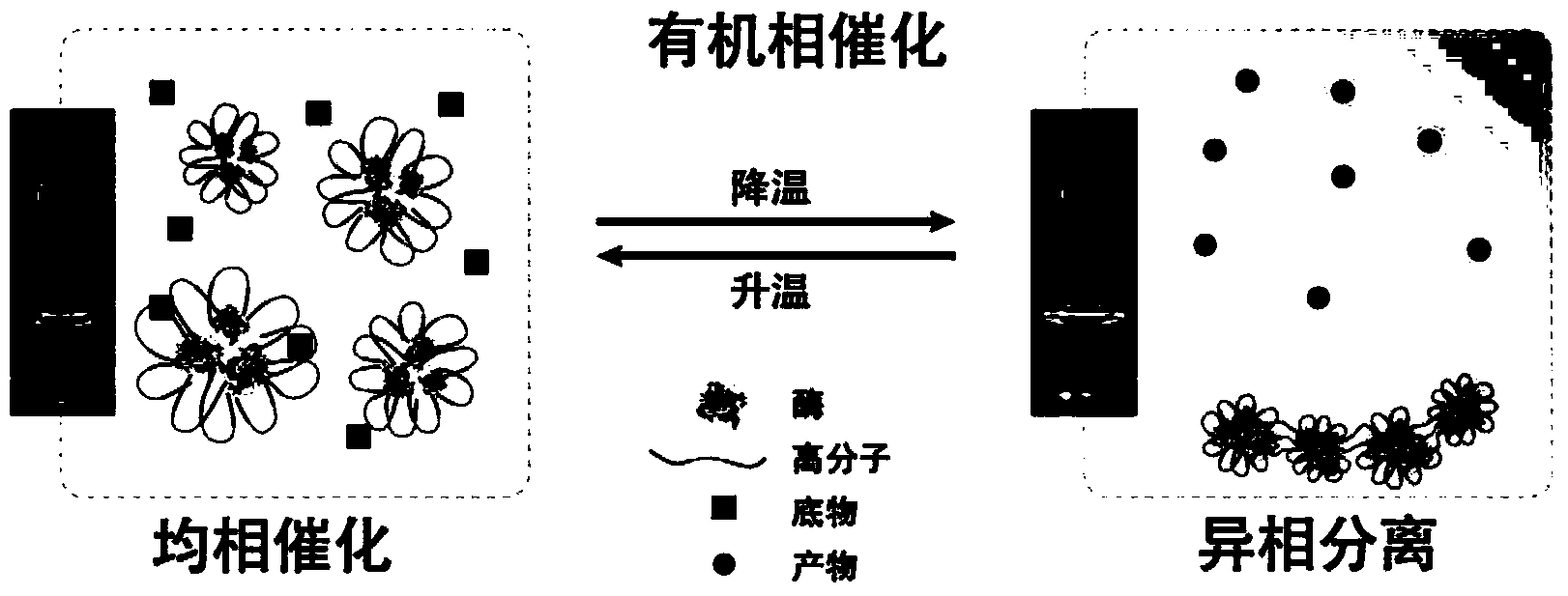

A technology of macromolecular conjugates and macromolecular compounds, which is applied in the direction of being fixed on/in organic carriers, can solve the problems of difficulty in recycling and utilization of enzyme preparations, and achieves easy industrial implementation and amplification, mild reaction conditions, and easy acquisition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The enzyme is Candida antarctica lipase B (enzyme activity is 9U / mg) which is 10 parts by weight, and the polymer compound is a compound with an average molecular weight of 12,600 60 parts by weight, 10 parts by weight of the activator Dess-Martin oxidant, and 6 parts by weight of sodium cyanoborohydride as the reducing agent.

[0063] 1) Dissolve the above-mentioned polymer and polymer activator in dichloromethane, carry out oxidation reaction at room temperature for 15 hours, oxidize the terminal hydroxyl group to aldehyde group, and then add cold ether to precipitate to obtain the activated polymer product, vacuum drying;

[0064] 2) Dissolve the activated polymer compound and enzyme obtained in step 1) in 10mM disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution with a pH value of 7, carry out the coupling reaction of aldehyde group and amino group at room temperature for 2 hours, then add The reducing agent carries out the reduction reaction of...

Embodiment 2

[0079] According to the steps of Example 1, only the raw materials of steps 1) and 2) are replaced as follows to obtain the enzyme-polymer conjugate provided by the present invention:

[0080] The enzyme is Candida rugosa lipase (enzyme activity: 700-1000U / mg) is 10 parts by weight, and the polymer is the average molecular weight of 12,600 It is 72 parts by weight, the polymer activator is 12 parts by weight of Dess-Martin oxidant, and the reducing agent is 7 parts by weight of sodium cyanoborohydride.

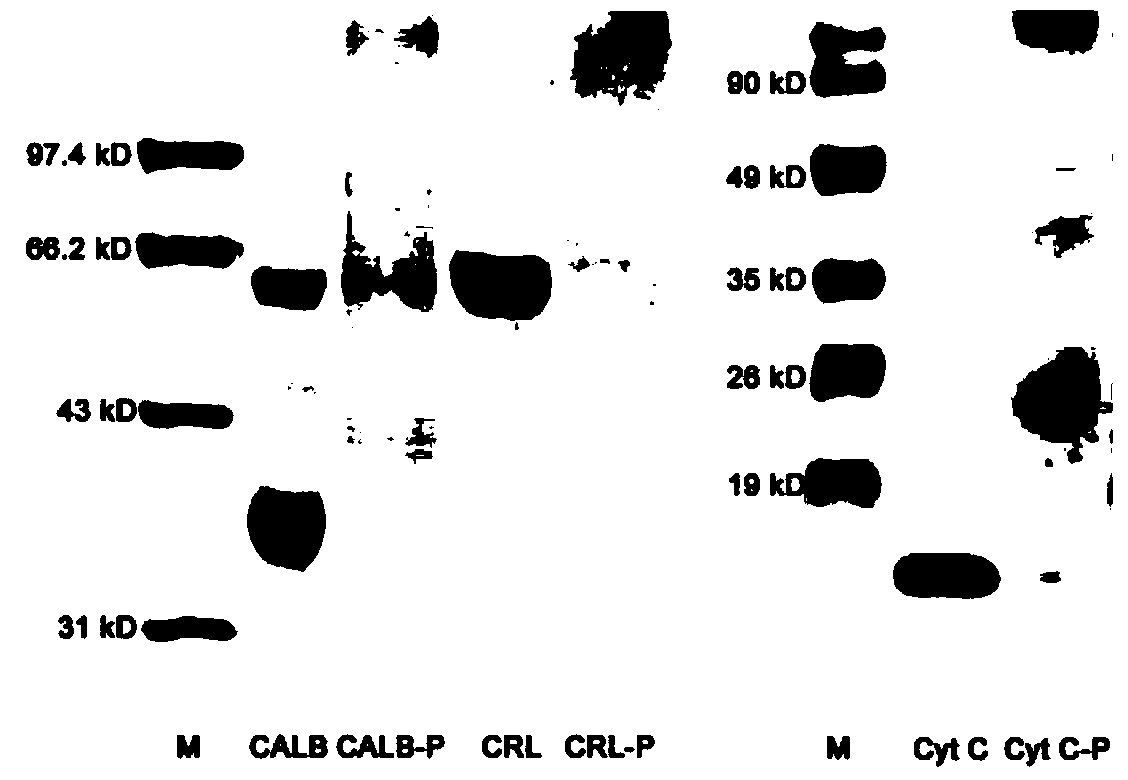

[0081] The enzyme-polymer conjugate SDS-PAGE results are as follows figure 2 shown.

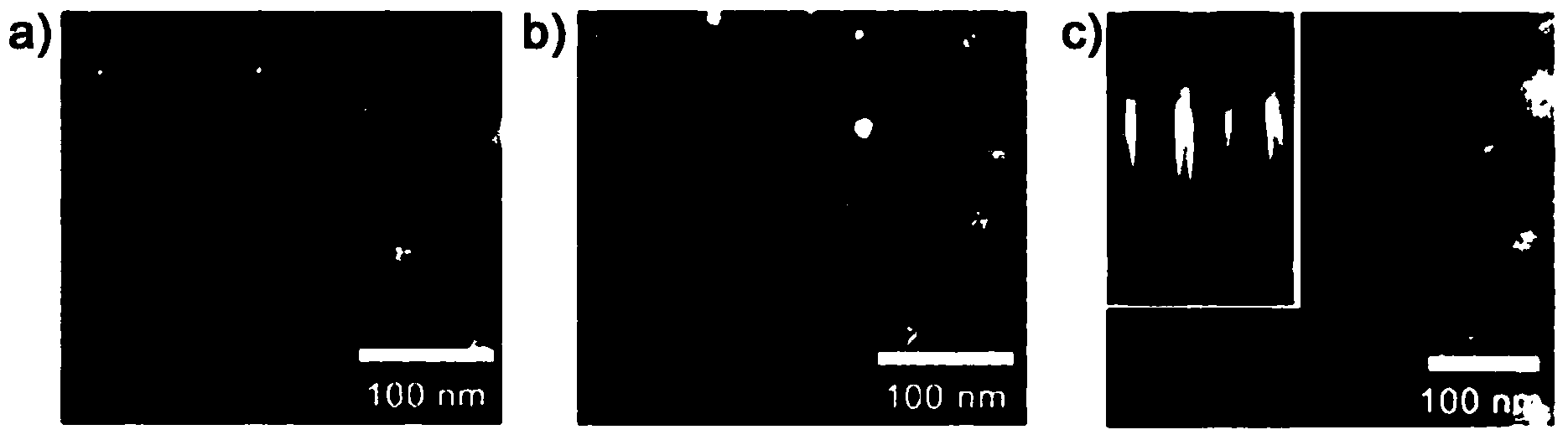

[0082] After dispersing in toluene, the particle size is 25nm ( image 3 b).

[0083] Evaluation:

[0084]1. Determination of the enzyme activity in the water phase as follows: First, dissolve p-nitrophenol palmitate in acetone, and then slowly add hydrogen phosphate containing 1.25% (w / v) Triton X-100 under stirring A 0.5 mM substrate solution was prepared in disodium-sodium dihydrog...

Embodiment 3

[0089] The enzyme is cytochrome C (enzyme activity is 12U / mg), 10 parts by weight, and the polymer compound is F-127 is 300 parts by weight, activator is 50 parts by weight of Dess-Martin oxidant, and reducing agent is 30 parts by weight of sodium cyanoborohydride.

[0090] Subsequent steps are the same as in Example 1.

[0091] The conjugate SDS-PAGE results are as follows figure 2 As shown, its particle size after dispersion in toluene is 30nm ( image 3 c).

[0092] Evaluation:

[0093] 1. Measure the enzyme activity in the water phase as follows: mix 960 μL ABTS aqueous solution (2.8 mg / mL) with 20 μL enzyme-polymer conjugate (enzyme content is 0.1 mg / ml), add an equivalent amount of natural enzyme aqueous solution to the control group (Cytochrome C, purchased from Sigma-Aldrich Company, the product number is C7752). Add 20 μL of hydrogen peroxide aqueous solution (0.3% v / v) to initiate the reaction, measure the absorbance at 415 nm versus time (a straight line wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com