Vitamin C chewable tablet and preparation method thereof

A technology for vitamins and chewable tablets, which is applied to pharmaceutical formulations, medical preparations with inactive ingredients, and medical preparations containing active ingredients, etc. Improved fluidity and tablet quality, reduced irritating sourness, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

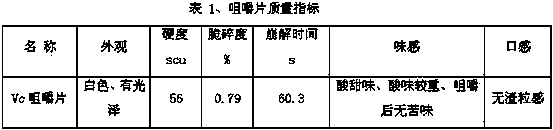

Embodiment 1

[0045]The formula of the chewable tablet is as follows: direct compression grade Vc97% granules, 18.36%; direct compression grade mannitol 100% granules, 44.9%; fructose powder, 10%; maltodextrin, 7.42%; microcrystalline cellulose 8.51%; silicon dioxide 4.45%; Eudragit 1.88%; stevia, 1.5%; magnesium stearate, 1.1%; lemon flavor 1.88%.

[0046] The preparation method is as follows:

[0047] 1. Preparation of direct pressure grade Vc97% granules:

[0048] ① Grinding: Vc crystal particles are pulverized by a small high-speed pulverizer for 6 seconds to 150-250 mesh; Vc-Ca crystal particles are pulverized by a small high-speed pulverizer for 5 seconds to 150-250 mesh.

[0049] ② Mixing: Add 500g of Vc powder into the V-shaped mixer, add 500g of Vc-Ca, and mix for 3 minutes.

[0050] ③Preparation of binder solution (also called pulping, the same below): Weigh 30g of HPMC with a viscosity of 3mpa.s, dissolve it in 400mL of purified water at 45°C for pulping, and prepare a binder s...

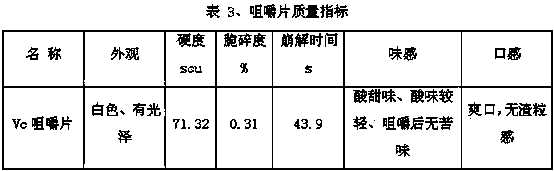

Embodiment 2

[0063] The formula of the chewable tablet is as follows: direct compression grade Vc97% granules, 18.36%; direct compression grade mannitol 100% granules, 39.15%; fructose powder, 13%; maltodextrin, 5.94%; microcrystalline cellulose 12.5%; silicon dioxide 6.5%; Eudragit, 1.59%; stevia, 0.74%; magnesium stearate, 1.48%; blueberry flavor, 0.74%.

[0064] The preparation method is as follows:

[0065] 1. Preparation of direct pressure grade Vc97% granules:

[0066] ① Grinding: Vc crystal particles are pulverized by a small high-speed pulverizer for 2 seconds to 150-250 mesh; Vc-Ca is pulverized by a small high-speed pulverizer for 6 seconds to 150-250 mesh.

[0067] ② Mixing: Add 500g of Vc powder into the V-type mixer, add 250g of Vc-Ca (vitamin calcium), and mix for 3 minutes.

[0068] ③Slurry mixing: Weigh 15g of HPMC and 3015g of PVPK with a viscosity of 3mpa.s, dissolve them in 250mL of purified water at 50°C for slurry mixing, and obtain a binder solution.

[0069] ④ Mul...

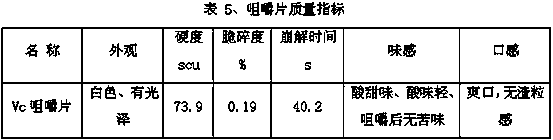

Embodiment 3

[0081] Chewable tablet formula: direct pressure grade Vc97% granules, 18.36%; direct pressure grade mannitol 100% granules, 43.53%; microcrystalline cellulose 19.30%; fructose, 7.5%; silicon dioxide 7.33%; stevia, 0.5% ; Eudragit, 1.0%; Magnesium Stearate, 1.48%; Blueberry Flavor 1.0%.

[0082] The preparation method is as follows:

[0083] 1. Preparation of direct pressure grade Vc97% granules:

[0084] ① Grinding: Vc crystal particles are pulverized by a small high-speed pulverizer for 5 seconds to 150-250 mesh; Vc-Ca is pulverized by a small high-speed pulverizer for 2 seconds to 150-250 mesh.

[0085] ② Mixing: Add 500g of Vc powder into the V-shaped mixer, add 1000g of Vc-Ca, and mix for 10 minutes.

[0086] ③Sizing: Weigh 20g of HPMC with a viscosity of 3mpa.s and 10g of pregelatinized starch, dissolve them in 450mL of purified water at 45°C for slurrying, and obtain a binder solution.

[0087] ④ Multifunctional fluidized bed dry granulation: Weigh 970g of the mixed m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com