N,N-dimethylglycine hydrochloride preparation method suitable for industrial production

A technology of dimethylglycine hydrochloride and dimethylamine, which is applied in the field of preparation of N,N-dimethylglycine hydrochloride, can solve the problems of many reaction by-products, expensive raw materials, and high cost, and achieve production The effect of simple process, high product purity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

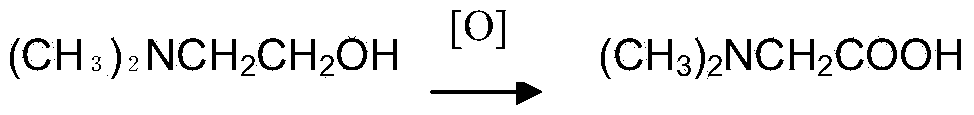

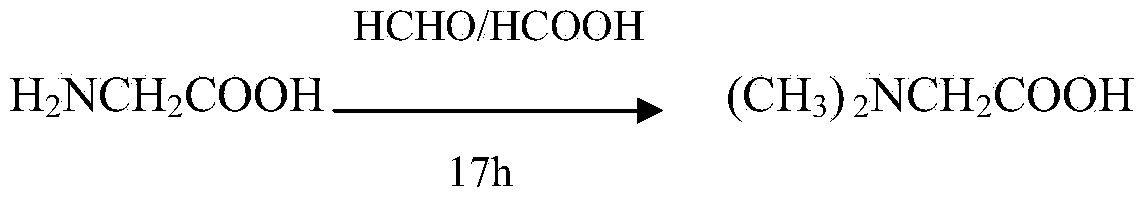

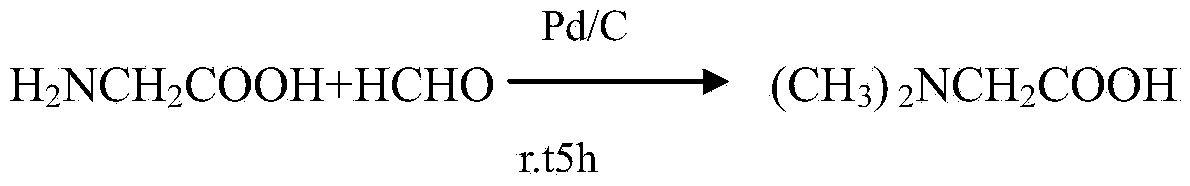

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Put 195kg of ethanol into the autoclave, start stirring, then add 200kg of solid chloroacetic acid (content 97.5wt%, the mass of pure chloroacetic acid is 195kg), 3.9kg of sodium iodide, after the solid chloroacetic acid dissolves, slowly pass it into the dry Dimethylamine gas is 93.02kg, and the reaction pressure is guaranteed to be 0.6MPa. After passing through, the temperature is controlled at 65°C, and the reaction is carried out for 4 hours. After the reaction is completed, the temperature is lowered to 25°C to release the pressure, and at the same time, unreacted dimethylamine is collected. After the dimethylamine was drained, the heated material was concentrated in vacuum, and ethanol was recovered. After white crystals were precipitated from the feed liquid, the concentration was stopped, and the temperature was lowered to 25°C, centrifuged, and dried to obtain 267.3kg of the product, with a content of 98.8% and a yield of 92.8%. The filtrate is set into the mate...

Embodiment 2

[0033] Put 292.5kg of dichloromethane into the autoclave, start stirring, then add 200kg of solid chloroacetic acid (content 97.5wt%, the mass of pure chloroacetic acid is 195kg), 7.8kg of sodium iodide, after the chloroacetic acid is dissolved, slowly pass in Dry dimethylamine gas 111.6kg, ensure the reaction pressure is 0.5MPa, pass through, control the temperature at 75 ° C, react for 6 hours, after the reaction is completed, the temperature will be lowered to 25 ° C to release the pressure, while collecting unreacted dimethylamine. After the dimethylamine is discharged, the heated material is concentrated in vacuum, and dichloromethane is recovered. After white crystals are precipitated from the material liquid, the concentration is stopped, the temperature is lowered to 25°C, centrifuged, and dried to obtain 269.2kg of the product, with a content of 99.3% and a yield of 93.5%. Apply the filtrate.

Embodiment 3

[0035] Put 220kg of isopropanol into the autoclave, start stirring, then add 200kg of solid chloroacetic acid (the content is 97.5wt%, the mass of pure chloroacetic acid is 195kg), 6kg of sodium iodide, after the chloroacetic acid dissolves, slowly pass it into the dry Dimethylamine gas is 94.2kg, and the reaction pressure is guaranteed to be 0.4MPa. After passing through, the temperature is controlled at 70°C, and the reaction is carried out for 5h. After the reaction is completed, the temperature is lowered to 25°C to release the pressure, and the unreacted dimethylamine is collected at the same time. After the dimethylamine was drained, the heated material was concentrated in vacuum, and isopropanol was recovered. After white crystals were precipitated from the material liquid, the concentration was stopped, and the temperature was lowered to 25°C, centrifuged, and dried to obtain 272.8kg of the product, with a content of 99.5% and a yield of 94.7%. Apply the filtrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com