POSS (Polyhedral Oligomeric Silsesquioxane) fluorosilicone acrylate-polyurethane blood compatible coating and preparation method thereof

A technology of siloxane fluorosilicone acrylate and blood compatibility, applied in the direction of polyurea/polyurethane coatings, coatings, etc., to achieve the effects of easy availability of raw materials, high practical value, and good blood compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

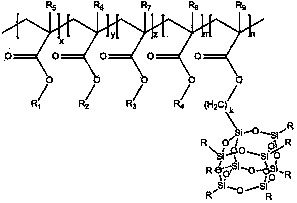

[0022] (1) Preparation of POSS fluorosilicone acrylate copolymer:

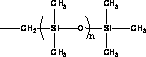

[0023]Preparation of POSS fluorosilicone acrylate copolymer by free radical polymerization: First, 5 g of butyl acetate (BA) and 5 g of methyl isobutyl ketone (MIBK) were added to a four-necked flask as a mixed solvent, and 0.15 g of azobis Isobutylcyanide (AIBN) was used as the initiator. After the temperature rises to 78°C, add 5.5 g of methyl methacrylate (MMA), 4.5 g of butyl acrylate (BA), and hydroxyethyl methacrylate (HEMA) into the four-necked flask dropwise at a rate of 7 ml / h. 1.5g, dodecafluoroheptyl methacrylate (DFMA) 3.5g, polydimethylsiloxane methacrylate (PDMS-MA) 0.8g, methacryloxy oligosilsesquioxane (POSS) 1.5g, AIBN 0.02g and 2g each of BA and MIBK. After the dropwise addition, react for 2-3 hours, then add 2 g each of BA and MIBK and 0.06 g of initiator AIBN into the four-neck flask, and react for 2-3 hours. The whole reaction was carried out under the protection of nitrogen atmosphere....

Embodiment 2

[0032] (1) Preparation of POSS fluorosilicone acrylate copolymer

[0033] Take free radical polymerization to prepare POSS fluorosilicone acrylate copolymer: first add butyl acetate (BA) 5g and methyl isobutyl ketone (MIBK) 5g as mixed solvent in four-necked bottle, and add with 0.12g azobis Isobutylcyanide (AIBN) was used as the initiator. After the temperature rose to 78°C, 6g of methyl methacrylate (MMA), 4g of butyl acrylate (BA), 2g of hydroxyethyl methacrylate (HEMA), Dodecafluoroheptyl methacrylate (DFMA) 3g, polydimethylsiloxane methacrylate (PDMS-MA) 1g, methacryloxy oligomeric silsesquioxane (POSS) 2g, AIBN 0.03g and 3g each of BA and MIBK. After the dropwise addition, react for 2-3 hours, then add 3 g each of BA and MIBK and 0.06 g of initiator AIBN into the four-neck flask, and react for 2-3 hours. The whole reaction was carried out under the protection of nitrogen atmosphere. Excess methanol was precipitated three times, and dried in a vacuum oven for 48 hours...

Embodiment 3

[0042] (1) Preparation of POSS fluorosilicone acrylate copolymer:

[0043] Take free radical polymerization to prepare POSS fluorosilicone acrylate copolymer: first add butyl acetate (BA) 6g and methyl isobutyl ketone (MIBK) 6g as mixed solvent in four-necked bottle, and add with 0.17g azobis Isobutylcyanide (AIBN) was used as the initiator. After the temperature rises to 78°C, add 6.5 g of methyl methacrylate (MMA), 5.5 g of butyl acrylate (BA), and hydroxyethyl methacrylate (HEMA) into the four-necked flask dropwise at a rate of 8 ml / h. 1.5 g, 3.5 g of dodecafluoroheptyl methacrylate (DFMA), 1.5 g of (meth)acryloxy oligomeric silsesquioxane (POSS), 0.03 g of AIBN, and 2 g each of BA and MIBK. After the dropwise addition, react for 2-3 hours, then add 3 g each of BA and MIBK and 0.06 g of initiator AIBN into the four-neck flask, and react for 2-3 hours. The whole reaction was carried out under the protection of nitrogen atmosphere. Excess methanol was precipitated three ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com