Tendon reinforcing repairing material and preparation method thereof

A technology of repair materials and composite materials, which is applied in the field of tendon-reinforced repair materials and its preparation, which can solve the problems of destroying the biocompatibility of the final product, inability to strengthen tendon repair, and limited ability of tissue regeneration, etc., to achieve the reduction of immunogen Safety and safety risks, increase anti-adhesion effect, and large coverage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1. Raw material processing: Remove the subcutaneous tissue from the newborn cowhide, wash it with pure water, remove the epidermis and basement membrane, cut it to a thickness of 0.3mm, soak it in medical alcohol for 1 hour, and transfer it to 4°C normal saline Soak to obtain the treated skin and set aside;

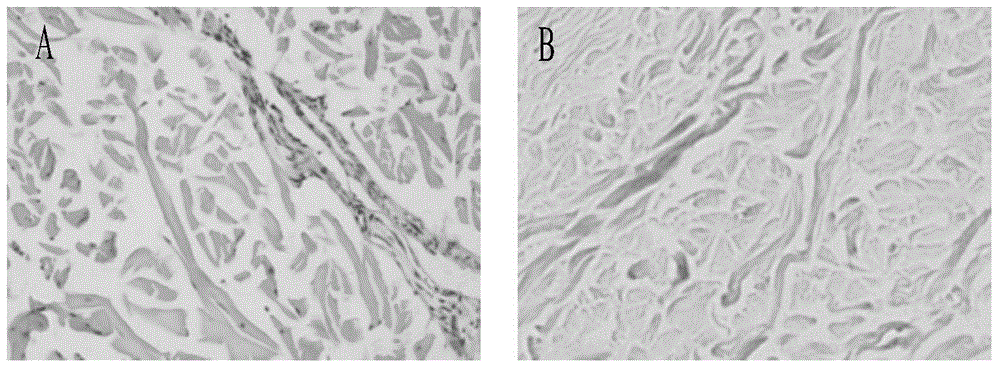

[0042] Step 2. Preparation of the scaffold layer of the tendon reinforcement repair material: place the treated skin obtained in step 1 in an aqueous solution containing 0.5% Triton X-100, shake at 4°C for 4 hours; put it in a 0.5mol / L NaCl aqueous solution for later use Shake at room temperature for 32 hours; obtain the decellularized bovine dermal matrix, that is, the scaffold layer of the tendon-reinforced repair material;

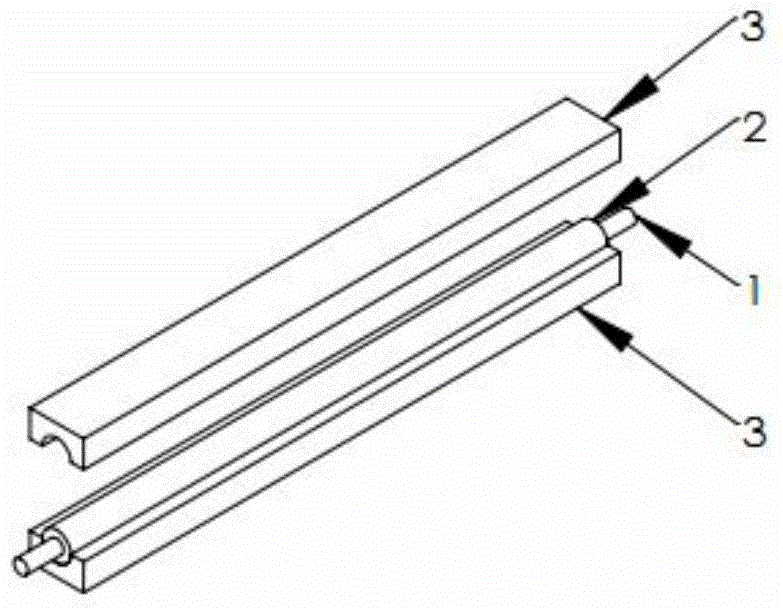

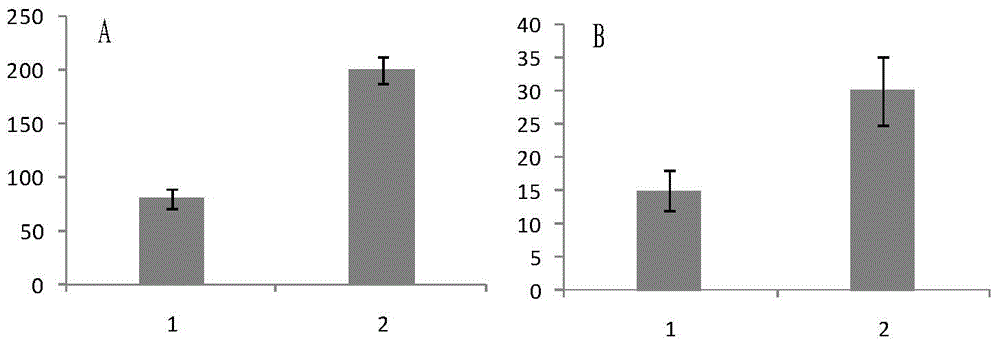

[0043] Step 3. Preparation of the mechanical reinforcement layer of the tendon reinforcement repair material: prepare a polylactic acid solution with a mass volume ratio of 5%, and compound the polymer on one surface of the decellulariz...

Embodiment 2

[0056] Step 1. Raw material processing: Remove the subcutaneous tissue from the newborn cowhide, wash it with pure water, remove the epidermis and basement membrane, cut it to a thickness of 0.5mm, soak it in medical alcohol for 2 hours, and transfer it to 4°C normal saline Soak to obtain the treated skin and set aside;

[0057] Step 2. Preparation of scaffold layer of tendon reinforcement repair material: place the treated skin obtained in step 1 in an aqueous solution containing 1% Triton X-100, shake at 4°C for 8h; then place in 10mM EDTA aqueous solution and shake at room temperature for 32h Obtain the decellularized bovine dermis matrix, that is, the scaffold layer of the tendon reinforcement repair material;

[0058]Step 3. Preparation of the mechanical reinforcement layer of the tendon reinforcement repair material: prepare a polylactic acid solution with a mass volume ratio of 5%, and compound the polymer on one surface of the decellularized bovine dermis matrix scaffo...

Embodiment 3

[0062] Step 1. Raw material processing: Remove the subcutaneous tissue of the adult pigskin, wash it with pure water, remove the epidermis and basement membrane, cut it to a thickness of 0.8mm, soak it in medical alcohol for 2 hours, and then transfer it to 4°C Soak in normal saline, get the treated skin, and set aside;

[0063] Step 2. Preparation of the scaffold layer of the tendon reinforcement repair material: place the treated skin obtained in step 1 in an aqueous solution containing 0.1% SDS, shake at 25°C for 3h; then put it in a 0.5mol / L NaCl aqueous solution and shake at room temperature for 32h Obtain the decellularized porcine dermal matrix, that is, the scaffold layer of the tendon reinforcement repair material;

[0064] Step 3. Preparation of the mechanical reinforcement layer of the tendon reinforcement repair material: prepare a polycaprolactone solution with a mass volume ratio of 6%, and compound the polymer on one surface of the acellular porcine dermal matri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com