A kind of stock solution of polyether type polyurethane sole

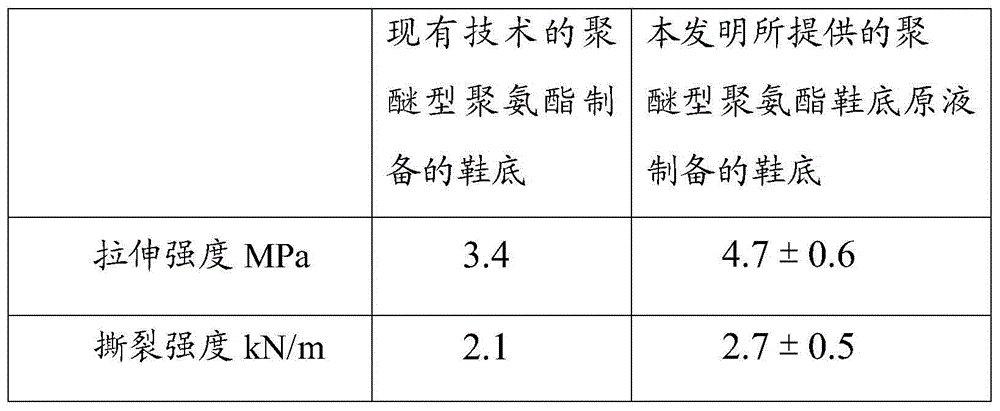

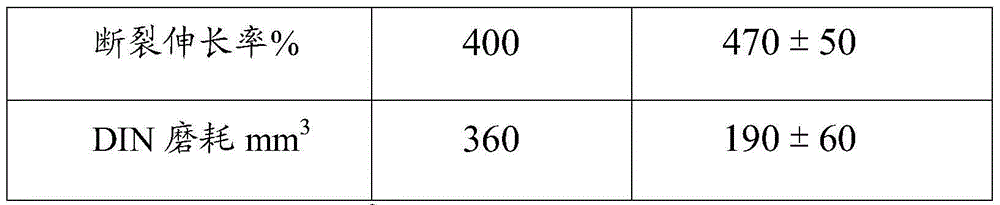

A technology of polyether polyurethane and stock solution, which is applied in the field of polyurethane materials, can solve the problems of low strength, poor physical properties, and non-abrasion resistance, and achieve good hydrolysis resistance, weather resistance and tortuous resistance, extended use range, and good physical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of polyester polyol

[0026] The preparation of polyester polyol can adopt the conventional preparation method of polyester polyol, and in this embodiment, nitrogen depressurization method is used for preparation.

[0027] The preparation process of polyethylene glycol diethylene glycol ester polyol with molecular weight about 2200:

[0028] Add 3300g of dimer acid, 270g of ethylene glycol, and 430g of diethylene glycol to the reaction kettle in sequence, turn on the stirring, start to raise the temperature, and at the same time, pass nitrogen gas into the upper part of the reaction kettle, and keep the temperature for 2 hours to stabilize the dehydration rate when the temperature is raised to 185-190°C (Through the rectification tower, the temperature at the top of the tower is maintained at <102°C) and then continue to increase the temperature until the temperature rises to about 210°C, switching nitrogen gas from the lower part of the reaction liquid, ...

Embodiment 2

[0037] The difference between embodiment two and embodiment one is:

[0038] 1. Synthesis of component A

[0039]Add 3500g of trifunctional polyether polyol with a molecular weight of about 4500, 500g of polymer polyol, 400g of 1,4-butanediol, 50g of diethylene glycol, and 40g of ethylene glycol solution of triethylenediamine into the reactor , deionized water 6g, dimethylsiloxane 30g, strength improving additive 200g; heat up to 50 ℃ ~ 60 ℃, stir at high speed for one hour and then lower the temperature to below 40 ℃, slowly add HCFC-141B 30g and then stir at low speed for 0.5 After h, component A is obtained.

[0040] 2. Synthesis of component B

[0041] Raw materials: 300 g of poly(ethylene glycol diethylene glycol) diethylene glycol ester polyol with a molecular weight of about 1800, 1,700 g of polyether polyol with a molecular weight of about 4,500, 4,4-diphenylmethane diisocyanate (MDI ) 2500g, liquefied MDI120g.

[0042] Add MDI, liquefied MDI, polyether polyol, pol...

Embodiment 3

[0044] The difference between embodiment three and embodiment one is:

[0045] 1. Synthesis of component A

[0046] Add 1500g of trifunctional polyether polyol with a molecular weight of about 6000, 1000g of a difunctional polyether polyol with a molecular weight of about 2000, 1000g of polymer polyol, 500g of 1,4-butanediol, triethylene 60g of ethylene glycol solution of diamine, 10g of deionized water, 20g of dimethyl siloxane, 300g of strength improving additive; heat up to 50°C-60°C, stir at high speed for one hour and lower the temperature to below 40°C, slowly Add 40g of HCFC-141B and stir at a low speed for 0.5h to obtain component A.

[0047] 2. Synthesis of component B

[0048] Raw materials: 500 g of polyethylene dimer acid diethylene glycol ester polyol with a molecular weight of about 2000, 1500 g of polyether polyol with a molecular weight of about 5000, 3000 g of MDI and 150 g of liquefied MDI prepared above.

[0049] Add MDI, liquefied MDI, polyether polyol, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com