Method for recycling and granulating secondary materials of high-performance glass fiber reinforced flame-retardant polybutylene adipamide

A polybutylene adipamide and secondary material technology, which is applied in the processing field of high temperature resistant engineering plastics, can solve the problems affecting the use of glass fiber reinforced flame retardant PA46 granulation material, the melt rupture of the die opening of the machine head, the secondary Uneven material flow and other problems, to achieve the effect of not easy sudden shear thinning, stable material flow performance, and fewer operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0037] The following examples 1 to 7 all adopt the following method to recycle and granulate the secondary material of high-performance glass fiber reinforced flame-retardant PA46:

[0038] (1) Crushing the secondary materials to be recycled (including secondary materials or unqualified parts produced during the injection molding process of glass fiber reinforced flame-retardant PA46) to obtain granular secondary materials to be recycled; When recycling the secondary material for crushing, the sealed medium-speed crushing method of 100 kg / hour can be used, and the length of the obtained granular secondary material to be recovered is less than or equal to 4cm;

[0039] (2) Put the granular secondary material to be recovered into the metal separator, and screen out the metal chips; when sieving the metal chip from the granular secondary material to be recovered, use the metal separator to separate it for 1 to 3 times , the separation speed is 50-200 kg / hour;

[0040] (3) After ...

Embodiment 1

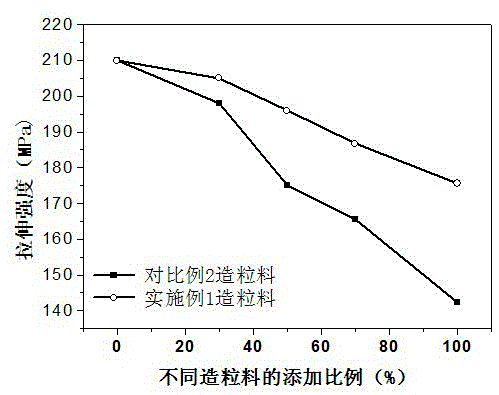

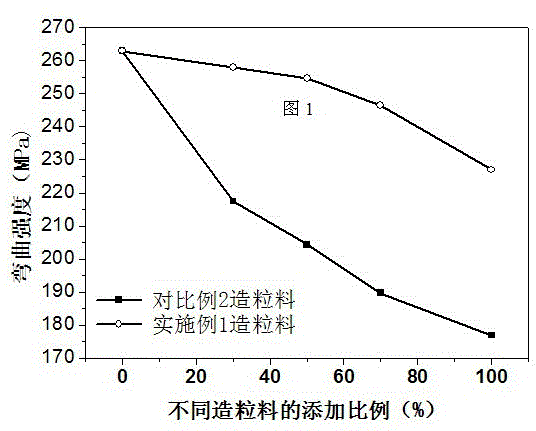

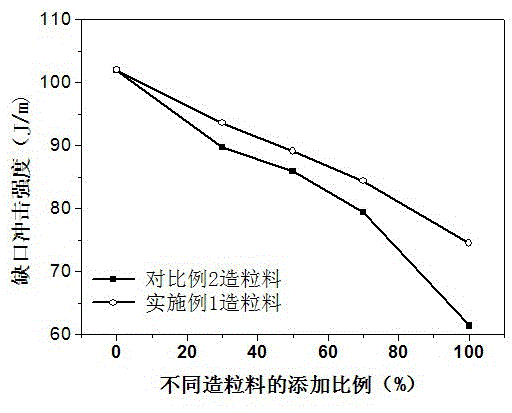

[0046] According to the above method, after crushing 200 kg of the secondary material to be recovered (GFFRPA46), put the granular secondary material to be recovered into the metal separator, screen out the metal chips, and extrude it through a single-rod extruder. The screw diameter of the single-screw extruder is 45mm, the length-to-diameter ratio is 18:1, the screw compression ratio is 3.0, the number of die holes: 2 holes, the die hole diameter is 3.0mm, and the extrusion temperatures are 305°C and 305°C, respectively. 310°C, 315°C, 310°C, the head temperature of the single-screw extruder is 310°C. The screw speed is 85rpm; the strands are cooled to about 120°C by the air-cooled conveyor belt, and then pelletized by the pelletizer. The obtained GFFRPA46 pellets (that is, the obtained recycled pellets) and the extrusion process are broken and agglomerated. The GFFRPA46 material cannot be pelletized and weighed. Weigh 15 kg of GFFRPA46 pellets and dry them at 120°C for 4 hou...

Embodiment 2

[0048] According to the above method, after crushing 200 kg of the secondary material to be recovered (GFFRPA46), put the granular secondary material to be recovered into the metal separator, screen out the metal chips, and extrude it through a single-rod extruder. The screw diameter of the single-screw extruder is 45mm, the length-to-diameter ratio is 25:1, the screw compression ratio is 3.1, the number of die holes: 2 holes, the die hole diameter is 3.5mm, and the extrusion temperatures are 305°C and 305°C, respectively. 310°C, 315°C, 310°C, the head temperature of the single-screw extruder is 310°C, and the screw speed is 115rpm; the strands are water-cooled and then pelletized by a pelletizer to obtain GFFRPA46 pellets (that is, the obtained Recycling pellets) and the extrusion process, the GFFRPA46 pellets cannot be pelletized due to broken bars and agglomerates, and weighed. The GFFRPA46 pellets of 15 kg were dried at 120°C for 4 hours, and injection molded into various p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com