Preparation method of water-soluble polystyrene-silicon dioxide core-shell type composite particle

A technology of polystyrene particles and silicon dioxide, applied in chemical instruments and methods, other chemical processes, polishing compositions containing abrasives, etc., can solve the problems of high cost of reagents, unsuitability for large-scale production, long reaction time, etc. , to achieve the effect of reducing production cost, reducing production risk and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

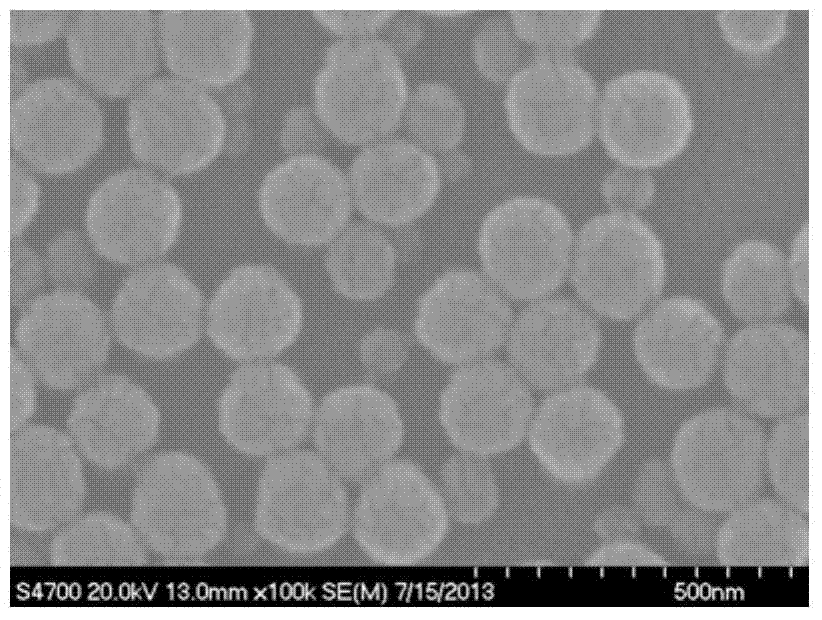

Image

Examples

Embodiment 1

[0035] Preparation of polystyrene-silica core-shell composite particles:

[0036](1) Add 1 gram of cationic polystyrene particles (average particle size 140nm) to every 50ml, 0.4wt% aqueous solution of poly-4-styrene sulfonate (PSS), after ultrasonic dispersion and adsorption for 20min, centrifuge, separate, Washing removes unadsorbed surfactant; Then add water to make an aqueous solution of polystyrene particles modified by PSS surface, wherein the concentration of polystyrene particles modified by PSS surface is 1wt%;

[0037] (2) Prepare an aqueous solution of trimethylchlorosilane (TMCS) and silicic acid, and adjust the pH value to 10 with potassium hydroxide aqueous solution with a concentration of 6wt% (if excessive potassium hydroxide aqueous solution is added during the adjustment process, nitric acid aqueous solution or hydrochloric acid can be used) The aqueous solution is reversed to ensure that the pH value is 10), and the alkaline aqueous solution of silicic acid ...

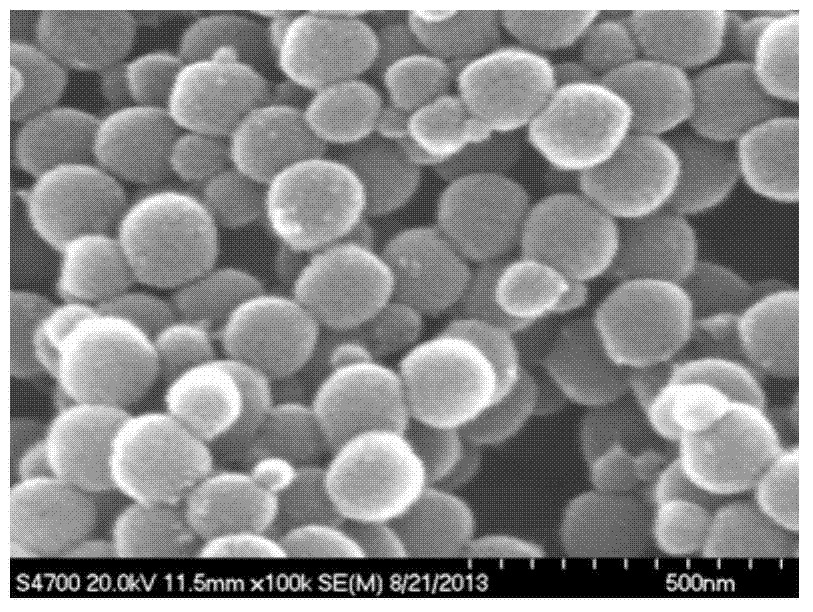

Embodiment 2

[0042] Preparation of polystyrene-silica core-shell composite particles:

[0043] (1) Add 1 gram of cationic polystyrene particles (average particle size 140nm) to every 50ml of 0.4wt% PSS aqueous solution, after ultrasonic dispersion and adsorption for 20min, remove unadsorbed surfactant by centrifugation, separation and washing; then add water Make the aqueous solution of the polystyrene particle through PSS surface modification, wherein the concentration of the polystyrene particle through PSS surface modification is 1wt%;

[0044] (2) Prepare an aqueous solution of TMCS and silicic acid, and adjust the pH value to 10 with a potassium hydroxide aqueous solution with a concentration of 6wt%, to obtain an alkaline aqueous solution of silicic acid treated with TMCS, wherein the concentration of silicic acid (in terms of SiO 2 Calculated) is 4wt%, the concentration of linker TMCS is 0.2wt%;

[0045] (3) Take 100 mL of the aqueous solution of PSS surface-modified polystyrene pa...

Embodiment 3

[0049] Preparation of polystyrene-silica core-shell composite particles:

[0050] (1) Add 1 gram of cationic polystyrene particles (average particle size 140nm) to every 50ml of 0.4wt% PSS aqueous solution, after ultrasonic dispersion and adsorption for 20min, remove unadsorbed surfactant by centrifugation, separation and washing; then add water Make the aqueous solution of the polystyrene particle through PSS surface modification, wherein the concentration of the polystyrene particle through PSS surface modification is 1wt%;

[0051] (2) Prepare an aqueous solution of TMCS and silicic acid, and adjust the pH value to 10 with a potassium hydroxide aqueous solution with a concentration of 6wt%, to obtain an alkaline aqueous solution of silicic acid treated with TMCS, wherein the concentration of silicic acid (in terms of SiO 2 Calculated) is 4wt%, the concentration of linker TMCS is 0.2wt%;

[0052] (3) Take 100 mL of the aqueous solution of PSS surface-modified polystyrene pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com