Composition for water shutoff and profile control, water-shutoff profile-control agent containing same and preparation methods

A technology of water plugging profile control and water profile control agent, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor temperature and salt resistance, limited application, environmental pollution, etc., achieve complete reaction, improve Conversion rate, source-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

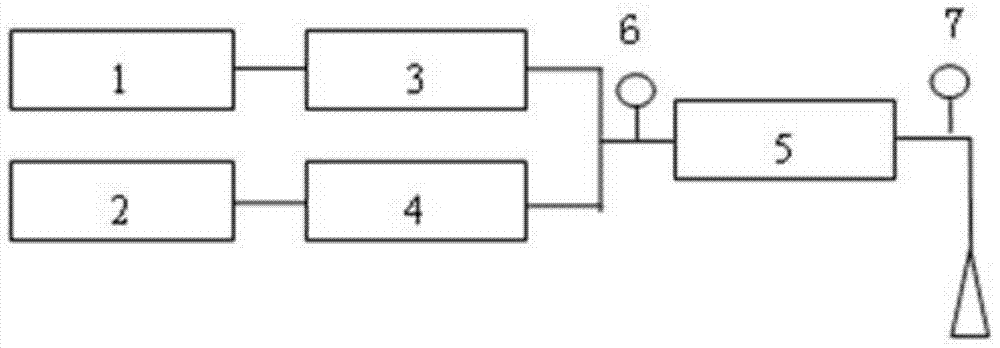

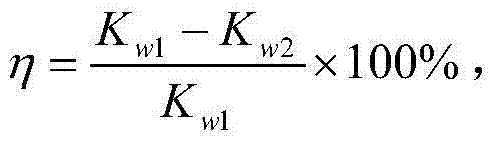

Method used

Image

Examples

Embodiment 1

[0044]This embodiment provides a composition for water plugging and profile modification. In terms of weight percentage, its raw material composition includes: 3% corn starch, 6% acrylamide, 0.4% composite initiator, 0.8% sodium hydroxide and the balance of water ; Wherein said composite initiator is mixed with mass ratio 1:1 by the hydrogen peroxide of ammonium persulfate composite initiator and mass concentration 50%, and described ammonium persulfate composite initiator comprises the ammonium persulfate that mass ratio is 1:3 and urea.

[0045] The preparation method of the composition for water plugging and profile control comprises the following steps:

[0046] Dissolving cornstarch in water with 60% of the total weight of raw material water to obtain an aqueous solution of cornstarch;

[0047] dissolving acrylamide in water with a total weight of 20% of the raw material water to obtain an aqueous solution of acrylamide;

[0048] The composite initiator is mixed with th...

Embodiment 2

[0055] This embodiment provides a composition for water plugging and profile modification. In terms of weight percentage, its raw material composition includes: 4% corn starch, 7% acrylamide, 0.8% composite initiator, 1% sodium hydroxide and the balance of water ; Wherein said composite initiator is mixed with mass ratio 1:3 by the hydrogen peroxide of ammonium persulfate composite initiator and mass concentration 50%, and described ammonium persulfate composite initiator comprises the ammonium persulfate that mass ratio is 1:3 and urea.

[0056] The preparation method of the composition for water plugging and profile control comprises the following steps:

[0057] Dissolving cornstarch in water with 60% of the total weight of raw material water to obtain an aqueous solution of cornstarch;

[0058] dissolving acrylamide in water with a total weight of 20% of the raw material water to obtain an aqueous solution of acrylamide;

[0059] The composite initiator is mixed with the...

Embodiment 3

[0066] This embodiment provides a composition for water plugging and profile modification. In terms of weight percentage, its raw material composition includes: 3.5% corn starch, 6.5% acrylamide, 0.6% composite initiator, 0.9% sodium hydroxide and water balance ; Wherein said composite initiator is mixed with mass ratio 1:2 by ammonium persulfate composite initiator and the hydrogen peroxide of mass concentration 50%, and described ammonium persulfate composite initiator comprises the ammonium persulfate that mass ratio is 1:3 and urea.

[0067] The preparation method of the composition for water plugging and profile control comprises the following steps:

[0068] Dissolving cornstarch in water with 60% of the total weight of raw material water to obtain an aqueous solution of cornstarch;

[0069] dissolving acrylamide in water with a total weight of 20% of the raw material water to obtain an aqueous solution of acrylamide;

[0070] The composite initiator is mixed with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com