Halloysite nano composite gel microspheres and preparation method thereof

A technology of nanocomposite and gel microspheres, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., and can solve the problem of complex carrier preparation process and high cost of carbon nanotube preparation , cytotoxicity and other issues, to achieve the effects of slowing down the drug release rate, good pH responsiveness, and slowing down the swelling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

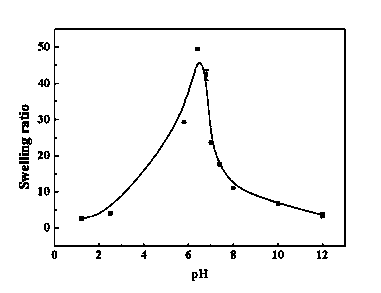

Embodiment 1

[0026] At 1000 rpm, halloysite was added to water to prepare a suspension with a concentration of 5%; at 1000 rpm, carboxymethyl chitosan was dissolved in water to prepare a suspension with a concentration of 3%. glue solution. The halloysite suspension was added into the carboxymethyl chitosan gel solution at 1000 rpm and stirred for 1 h, and then ultrasonically treated at a power of 100 w and a frequency of 60 kHz for 30 min. At 500 rpm, drop the mixed solution into 5% calcium chloride solution with a syringe, stir for 3 hours, filter the nanocomposite gel particles, rinse with distilled water, and vacuum dry to obtain halloysite nanocomposite gel microspheres . The nanocomposite gel microspheres have a diameter of 2-4 mm, hardly swell at pH=2, and have a swelling ratio of 50 at pH=6.8.

Embodiment 2

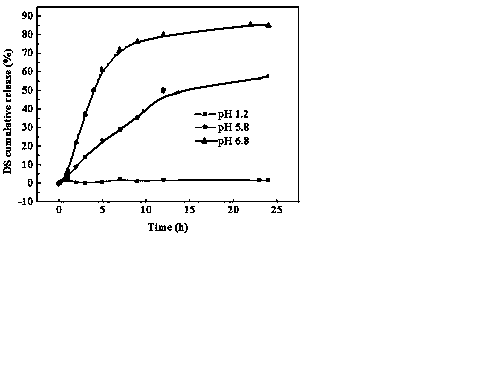

[0028] At 1000 rpm, halloysite was added to water to prepare a suspension with a concentration of 5%; at 1000 rpm, carboxymethyl chitosan was dissolved in water to prepare a suspension with a concentration of 3%. glue solution. Add the halloysite suspension into the carboxymethyl chitosan gel solution at 1000 r / min, add diclofenac sodium at the same time and stir for 1 hour, then ultrasonicate for 30 minutes at a power of 100w and a frequency of 60kHz. At 500 rpm, drop the mixed solution into 5% calcium chloride solution with a syringe, stir for 3 hours, filter the nanocomposite gel particles, rinse with distilled water, and vacuum dry to obtain halloysite nanocomposite gel microspheres . At pH=1.2, almost no drug was released, but at pH=6.8, the 24h drug release rate reached 85%.

Embodiment 3

[0030] At 1000 rpm, halloysite was added to water to prepare a suspension with a concentration of 7%; at 1000 rpm, quaternary ammonium chitosan was dissolved in water to prepare a suspension with a concentration of 3%. glue solution. At 1000 rpm, the halloysite suspension was added into the quaternary ammonium chitosan gel solution and stirred for 1 h, and then ultrasonically treated at a power of 100 w and a frequency of 60 kHz for 30 min. At 500 rpm, drop the mixed solution into 5% calcium chloride solution with a syringe, stir for 3 hours, filter the nanocomposite gel particles, rinse with distilled water, and vacuum dry to obtain halloysite nanocomposite gel microspheres . The nanocomposite gel microspheres have a diameter of 3-4 mm, hardly swell at pH=2, and have a swelling ratio of 46 at pH=6.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com