Preparation method of catalyst for ethylene polymerization

A catalyst and polyethylene technology, applied in the field of polyethylene catalyst preparation, can solve the problems of low solubility, unsatisfactory catalyst polymerization efficiency, high content, etc., achieve stable reaction, easy temperature control, and increase the effect of loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

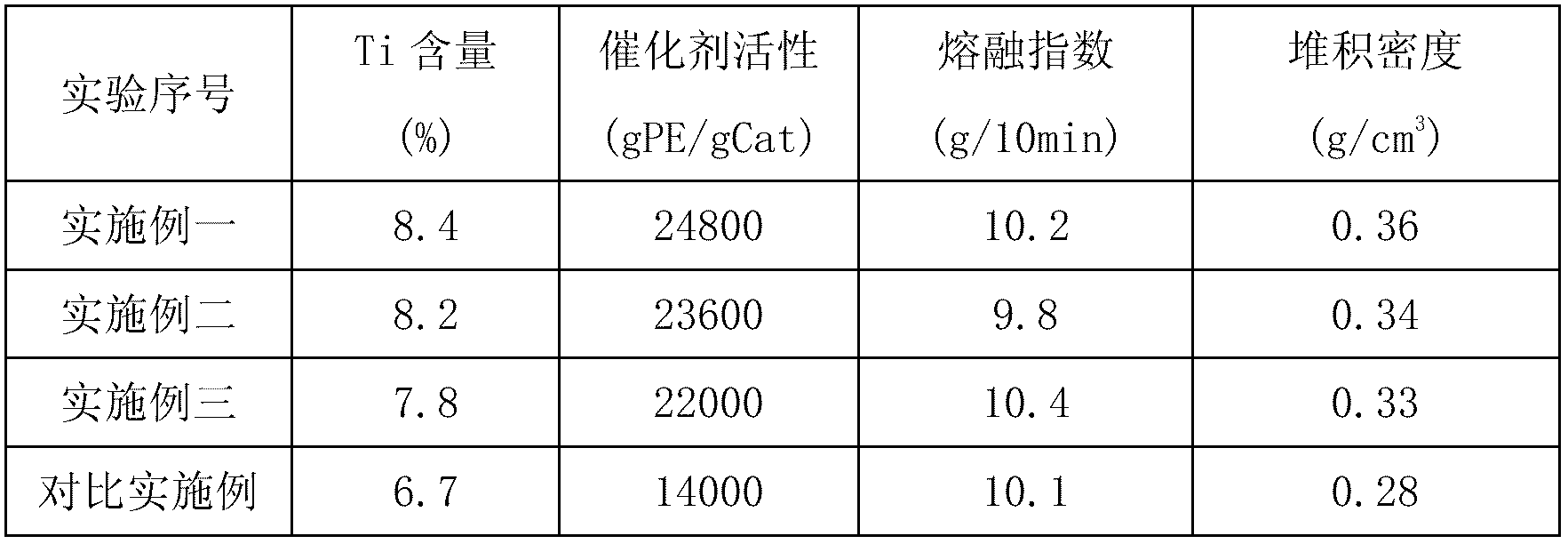

Examples

Embodiment 1

[0020] 1. Catalyst preparation

[0021] Add 50ml of dichloromethane, 8.1g of C 2 h 5 OCl and 10.1g triethylamine and 9.5g anhydrous magnesium chloride, react at -10°C for 1 hour, add 20g triethylaluminum to the system, react at 50°C for 2 hours, then add 300ml tetrahydrofuran, react for 2 hours , filter out a small amount of solid components at the bottom, and leave the supernatant for later use.

[0022] Add 2g of smoky silica gel to the above solution, keep stirring at 40°C for 1 hour, then introduce it into the spray dryer under the protection of nitrogen, set the inlet temperature of the spray dryer to 140°C, and the outlet temperature of the slurry material to 40°C, adjust the atomization airflow and the power of the slurry feed pump, so that the outlet temperature of the spray dryer is stabilized at about 90°C for spraying to obtain a microspherical catalyst carrier powder with an average particle size of 25 μm.

[0023] Take 5g of the above-mentioned microspherical c...

Embodiment 2

[0027] 1. Catalyst preparation

[0028] Add 50ml of dichloromethane, 10.8g of C 6 h 5 OCl and 10.7g triethylamine and 9.5g anhydrous magnesium chloride, react at room temperature for 1 hour, add 20g triethylaluminum, react at 60°C for 2 hours, then add 380ml ethyl acetate, react for 2 hours, filter A small amount of solid components at the bottom were discarded, and the supernatant was reserved for future use.

[0029] Add 2g of smoky silica gel to the above solution, keep stirring at 40°C for 1 hour, then introduce it into the spray dryer under the protection of nitrogen, set the inlet temperature of the spray dryer to 140°C, and the outlet temperature of the slurry material to 40°C, adjust the atomization airflow and the power of the slurry feed pump, so that the outlet temperature of the spray dryer is stabilized at about 90°C for spraying to obtain a microspherical catalyst carrier powder with an average particle size of 25 μm.

[0030] Take 5g of the above-mentioned mi...

Embodiment 3

[0034] 1. Catalyst preparation

[0035] Add 50ml of dichloromethane, 10.8g of C 6 h 5 OCl and 18.5g tributylamine and 9.5g anhydrous magnesium chloride, react at room temperature for 1 hour, add 30g diethylaluminum chloride, react at 45°C for 2 hours, then add 400ml ethyl benzoate, react for 2 hours Finally, filter out a small amount of solid components at the bottom, and leave the supernatant for future use.

[0036] Add 4g of smoky silica gel to the above solution, keep stirring at 40°C for 1 hour, then introduce it into the spray dryer under the protection of nitrogen, set the inlet temperature of the spray dryer to 140°C, and the outlet temperature of the slurry liquid to 40°C, adjust the atomization The air flow and the power of the slurry feed pump make the spray dryer outlet temperature stable at about 90°C for spraying. The microspherical catalyst carrier powder with an average particle diameter of 25 μm was obtained.

[0037]Take 5g of the above-mentioned microsph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com