Surface enhanced Raman scattering substrate, preparation method therefor and application thereof

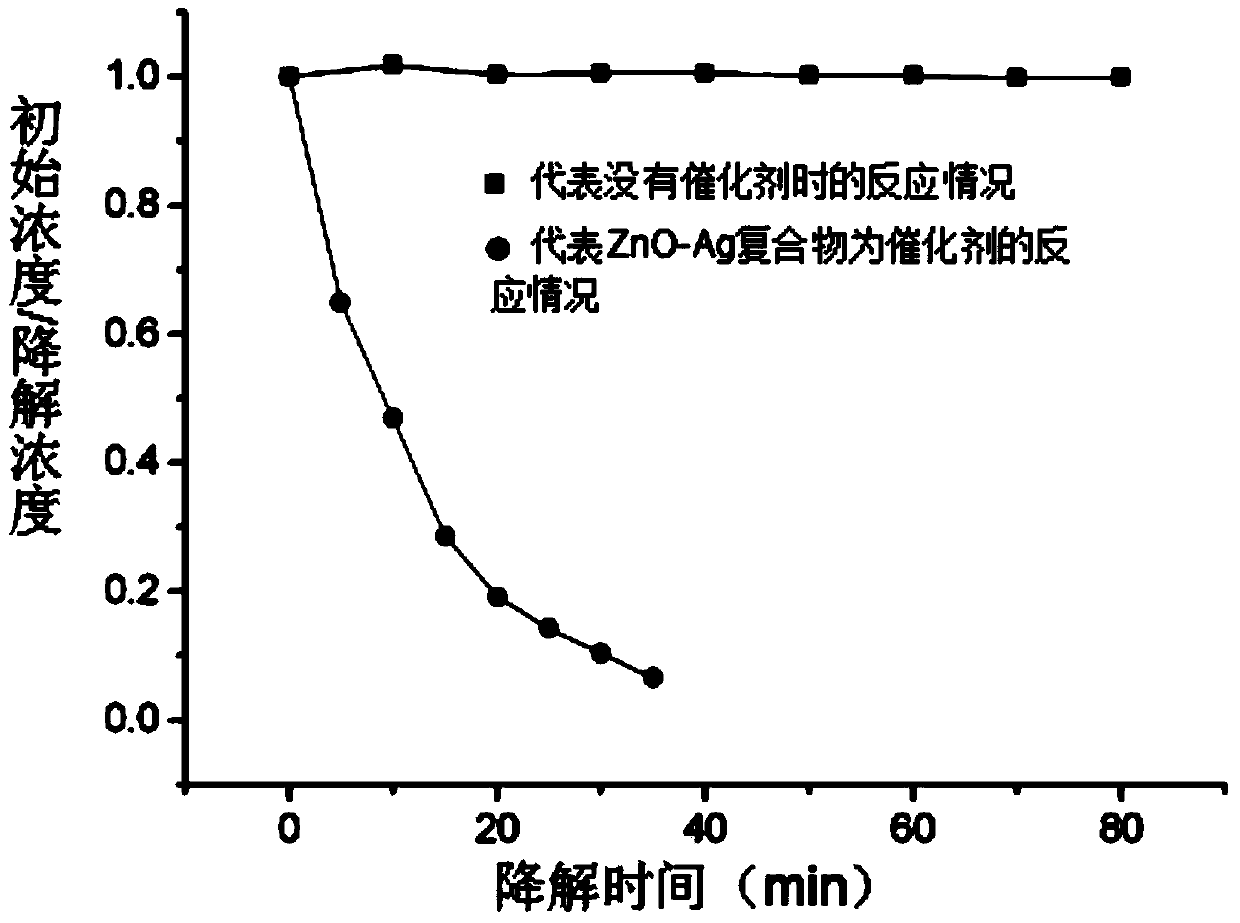

A surface-enhanced Raman and substrate technology, applied in Raman scattering, chemical instruments and methods, sputtering plating, etc., can solve the problems of complex preparation process, unreusable, unfavorable practical application, etc. The surface distribution is dense and uniform, and the effect of good photocatalytic reaction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Step 1: Cut the ITO conductive glass into strips of 1.5cm×1.5cm, ultrasonically clean them one by one with acetone, alcohol, and deionized water and dry them, and place them vertically in an airtight container for later use;

[0048] Step 2: Weigh 3.7186g of Zn(NO 3 ) 2 ·6H 2 O (purity 99.998%) powder was dissolved in deionized water to prepare 0.05mol / L Zn(NO 3 ) 2 solution, and then to Zn(NO 3 ) 2 Add isopropanol to the water-alcohol volume ratio of 3:1 in the solution to form the first mixed solution; after stirring the first mixed solution for 30 minutes to fully activate, add ammonia with a mass fraction of 25% to the first mixed solution dropwise Aqueous solution, control the volume ratio of the first mixed solution to the ammonia solution to be 1:4 to form the second mixed solution, pour the second mixed solution into the airtight container with the ITO conductive glass treated in step 1, and keep the temperature of the water bath at 90°C React for 6 hours,...

Embodiment 2

[0052] Repeat Example 1, other conditions are the same, only the volume ratio of the first mixed solution and ammonia solution in step 2 is changed to 1:2. The ZnO material prepared in step 2 of Example 2 was scanned by electron microscope (FE-SEM), and the results are shown in Figure 8 ,Such as Figure 8 As shown, when the volume ratio of the first mixed solution to the ammonia solution is 1:2, irregular nano-zinc oxide dendritic structures are obtained.

Embodiment 3

[0054] Repeat Example 1, other conditions are the same, only the volume ratio of the first mixed solution and ammonia solution in step 2 is changed to 1:3. The ZnO material prepared in step 2 of Example 3 was scanned by electron microscope (FE-SEM), and the results are shown in Figure 9 ,Such as Figure 9 As shown, when the volume ratio of the first mixed solution to the ammonia solution is 1:3, irregular nano-zinc oxide cluster structures are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com