Method for preparing topological insulator Bi2Se3 film

A topological insulator and thin film technology, applied in chemical instruments and methods, crystal growth, from condensed steam, etc., can solve the problems of expensive equipment, high cost, and large energy consumption, and achieve lower concentration, lower equipment requirements, and reduced Se The effect of vacancy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

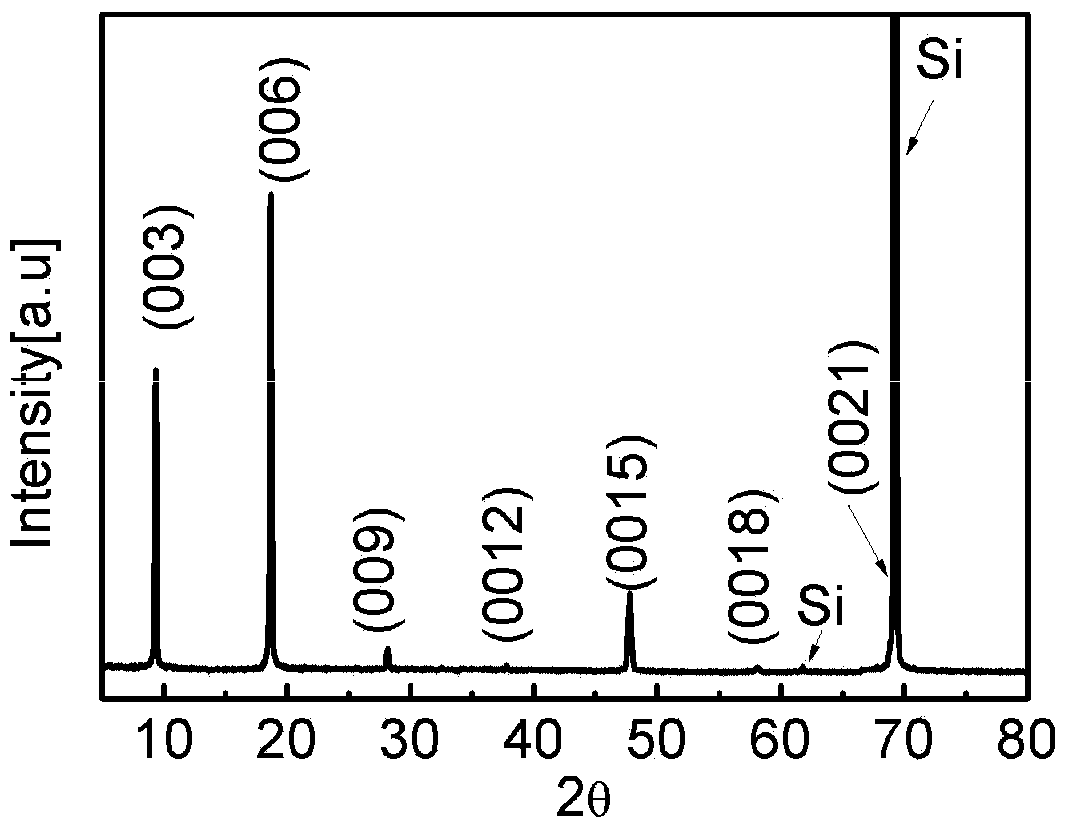

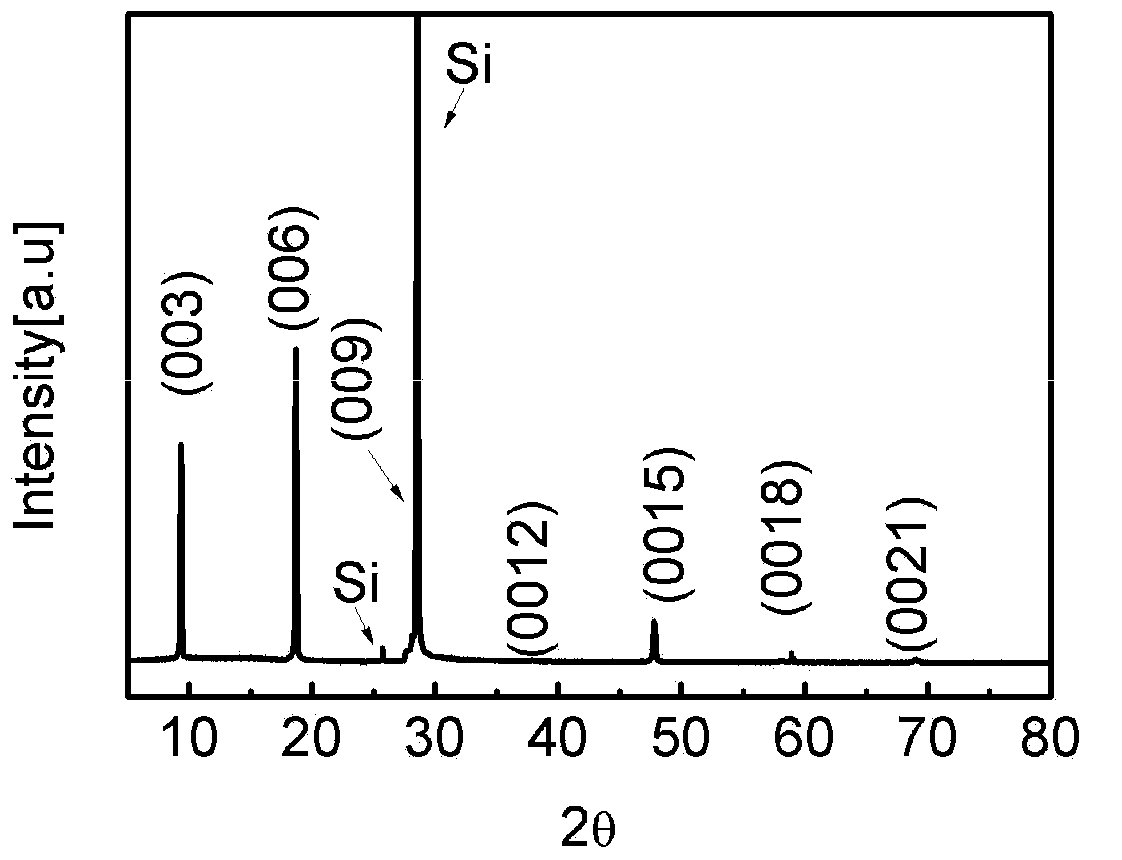

Image

Examples

Embodiment 1

[0031] A preparation of topological insulator Bi 2 Se 3 The method of thin film, its step is:

[0032] a. Preparation of single crystal blocks: Bismuth powder (Bi) with a purity of 99.999% and selenium powder (Se) with a purity of 99.999% were weighed in an argon glove box, ground, and pressed in a molar ratio of 2:3.2. slices; repacking air pressure is less than 1×10 -2 The vacuum quartz tube of Pa is placed in a tube furnace for sintering under an argon protective atmosphere, and then the vacuum quartz tube is pushed into cold water for quenching to obtain Bi 2 Se 3 monocrystalline block;

[0033] The temperature and time of sintering in the tube furnace are: heating up to 850°C for 5 hours, holding at 850°C for 12 hours, then uniformly cooling down to 620°C for 50 hours, and holding for 5 hours;

[0034] b. Precursor powder preparation: the Bi in step a 2 Se 3 The single crystal block was put back into the argon glove box and ground into powder;

[0035] c. Evaporat...

Embodiment 2

[0041] A preparation of topological insulator Bi 2 Se 3 The method of thin film, its step is:

[0042] a. Preparation of single crystal blocks: Bismuth powder (Bi) with a purity of 99.999% and selenium powder (Se) with a purity of 99.999% were weighed in an argon glove box, ground, and pressed in a molar ratio of 2:3.2. slices; repacking air pressure is less than 1×10 -2 The vacuum quartz tube of Pa is placed in a tube furnace for sintering under an argon protective atmosphere, and then the vacuum quartz tube is pushed into cold water for quenching to obtain Bi 2 Se 3 monocrystalline block;

[0043] The temperature and time of sintering in the tube furnace are: heating up to 850°C for 5 hours, holding at 850°C for 12 hours, then uniformly cooling down to 620°C for 50 hours, and holding for 5 hours;

[0044] b. Precursor powder preparation: the Bi in step a 2 Se 3 The single crystal block was put back into the argon glove box and ground into powder;

[0045] c. Evaporat...

Embodiment 3

[0051] A preparation of topological insulator Bi 2 Se 3 The method of thin film, its step is:

[0052] a. Preparation of single crystal blocks: Bismuth powder (Bi) with a purity of 99.999% and selenium powder (Se) with a purity of 99.999% were weighed in an argon glove box, ground, and pressed in a molar ratio of 2:3.2. slices; repacking air pressure is less than 1×10 -2 The vacuum quartz tube of Pa is placed in a tube furnace for sintering under an argon protective atmosphere, and then the vacuum quartz tube is pushed into cold water for quenching to obtain Bi 2 Se 3 monocrystalline block;

[0053] The temperature and time of sintering in the tube furnace are: heating up to 850°C for 5 hours, holding at 850°C for 12 hours, then uniformly cooling down to 620°C for 50 hours, and holding for 5 hours;

[0054] b. Precursor powder preparation: the Bi in step a 2 Se 3 The single crystal block was put back into the argon glove box and ground into powder;

[0055] c. Evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com