Wet method for preparing iron oxide red through introducing crystal form accelerant

A technology of iron oxide red and accelerator, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of low output of single group iron red, high oil absorption of products, high production cost, etc., and achieve low iron hydrate content, Low oil absorption and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

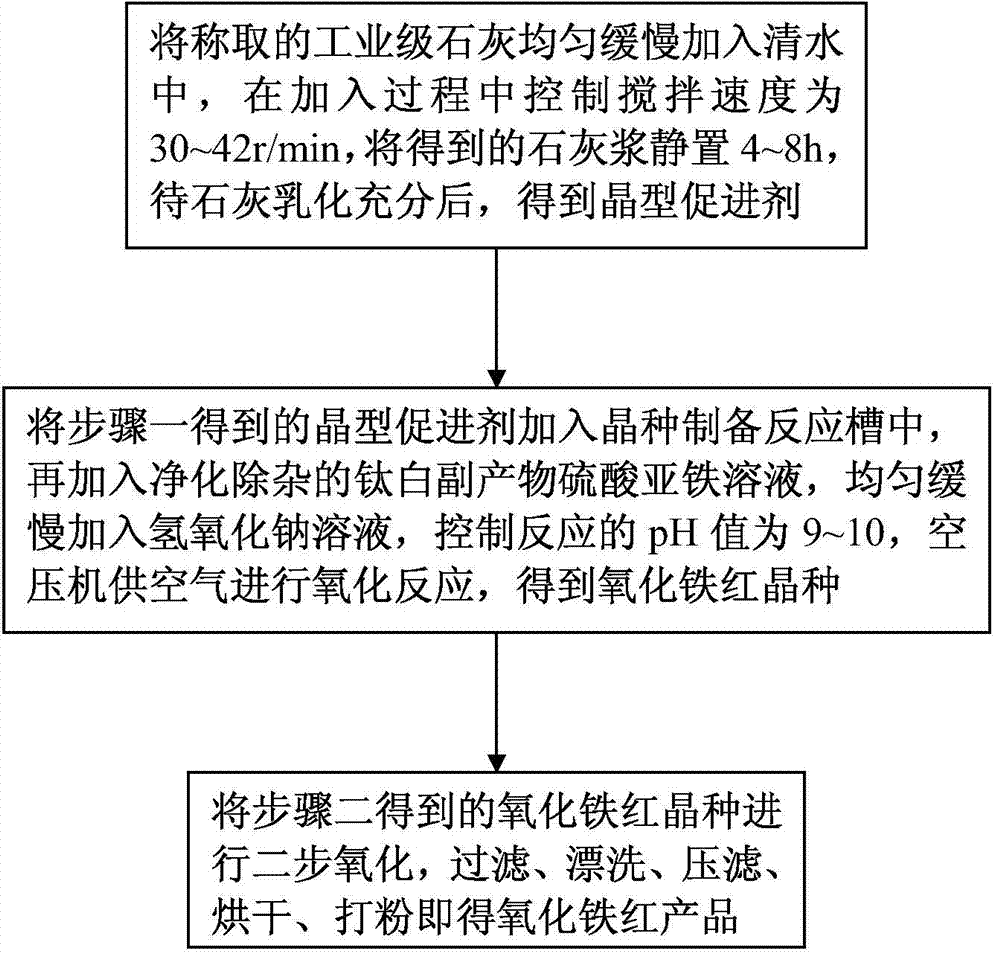

[0032] Such as figure 1 Shown, the present invention provides a kind of method that introduces crystal formation promoter wet preparation iron oxide red, comprises the following steps:

[0033] Step 1. Add the weighed industrial-grade lime into clean water evenly and slowly. During the adding process, control the stirring speed at 30-42r / min. Let the obtained lime slurry stand for 4-8 hours. After the lime is fully emulsified, the crystal form is obtained. Accelerator;

[0034] Step 2: Add the crystal form promoter obtained in Step 1 into the seed crystal preparation reaction tank, and then add 1500-2300 kg of titanium dioxide by-product ferrous sulfate solution with a concentration of 400-480 g / L for purification and removal of impurities. The feeding process continues Aft...

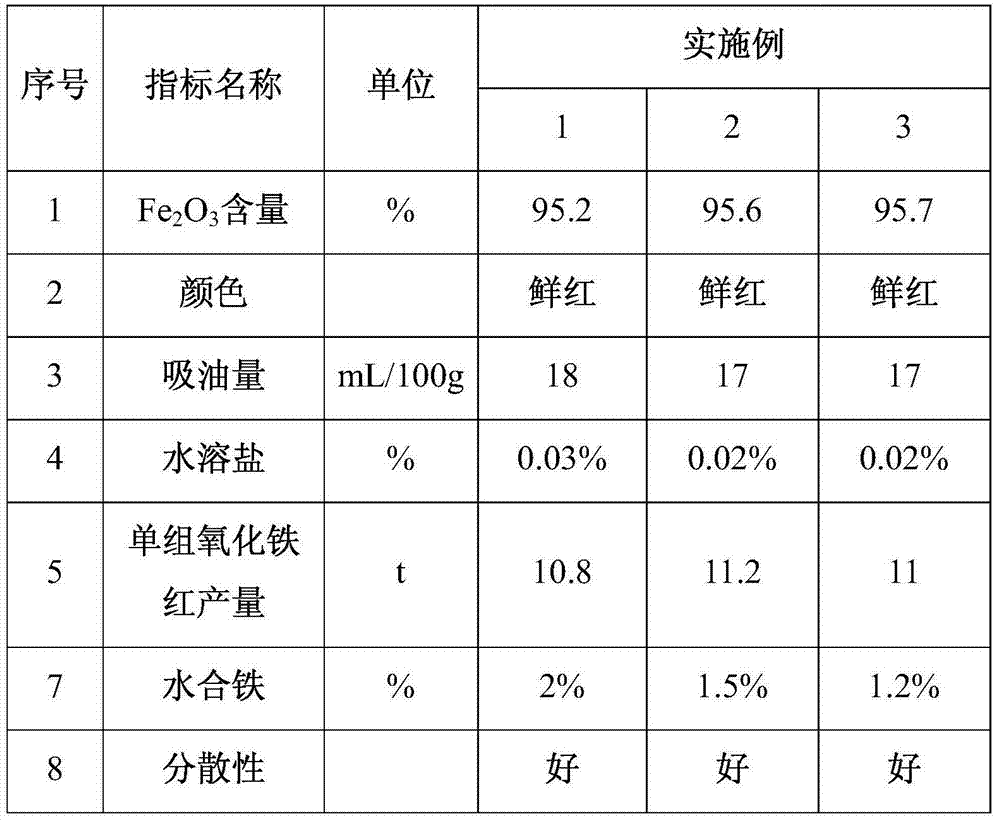

Embodiment 1

[0056] Step 1, preparation of crystal accelerator

[0057] a. Add 18.5m 3 clean water;

[0058] B. take by weighing 235kg content be the industrial grade lime of 80%;

[0059] c. Add the industrial grade lime weighed in step b evenly and slowly into the crystal accelerator preparation tank. The feeding process lasts for 10 minutes, and the stirring speed is controlled at 30r / min for 5 minutes, and then the stirring speed is controlled at 38r / min to continue stirring For 12 minutes, the crystal formation accelerator preparation tank was placed in a low-temperature closed box at 6°C for reaction;

[0060] Stop stirring after 5 minutes after the end of step d.c;

[0061] e. Let the lime slurry obtained in step d stand for 4 hours, adjust the temperature of the low-temperature closed box to 1° C., and obtain the crystal accelerator after the lime emulsification is sufficient;

[0062] Step 2. Introducing a crystal form accelerator to prepare iron oxide red seed crystals by wet...

Embodiment 2

[0073] a. Add 18.5m 3 clean water;

[0074] B. take by weighing 235kg content be the industrial grade lime of 80%;

[0075] c. Evenly and slowly add the industrial-grade lime weighed in step b into the crystal accelerator preparation tank, the feeding process lasts for 15 minutes, control the stirring speed to 33r / min and stir for 8 minutes, then control the stirring speed to 40r / min to continue stirring For 15 minutes, the crystal formation accelerator preparation tank was placed in a low-temperature closed box at 8°C for reaction;

[0076] Stop stirring after 5 minutes after the end of step d.c;

[0077] e. Leave the lime slurry obtained in step d for 6 hours, adjust the temperature of the low-temperature closed box to 2° C., and obtain the crystal accelerator after the lime emulsification is sufficient;

[0078] Step 2. Introducing a crystal form accelerator to prepare iron oxide red seed crystals by wet method

[0079] a. Add the crystal form promoter prepared in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com