Preparation method for ivory color-imitating yttrium oxide and praseodymium oxide co-stabilized tetragonal zirconia nano ceramic powder

A nano-ceramic powder, phase zirconia technology, applied in the field of bioceramics, can solve the problems of unfavorable dental tissue protection, uneven coloring, increased tooth preparation, etc., and achieves improved mechanical properties, short synthesis time, and reduced ceramic sintering temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

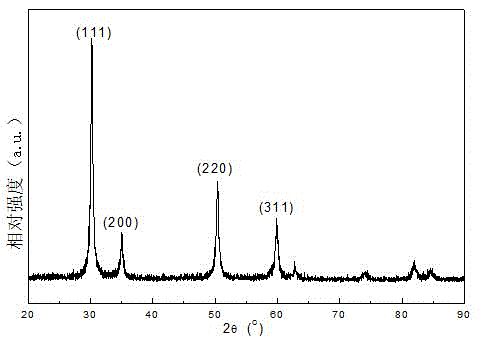

Embodiment 1

[0025] Weigh 3. 1137g ZrOCl 2 ·8H 2 O, 0.0339g Y 2 o3 and 0.0077g Pr 6 o 11 , adding an excess of 1:1 nitric acid and heating to dissolve Y 2 o 3 and Pr 6 o 11 , to form a clear solution of yttrium nitrate and praseodymium nitrate, the weighed ZrOCl 2 ·8H 2 O is completely dissolved in it to obtain a mixed salt solution of the metal contained in the target product, then add 1.7532g NaCl and 1.7113g glycine to the solution, heat and dissolve completely, then concentrate the mixed solution until it is viscous, and put it into the set temperature It is ignited in a chamber with a constant temperature of 500°C. After the combustion is completed, the sample is taken out, washed, filtered, and dried to obtain a specific surface area of 128 m 2 g -1 of (Pr 6 o 11 ) 0.00075 (Y 2 o 3 ) 0.015 (ZrO 2 ) 0.9655 Pale yellow powder.

Embodiment 2

[0027] Weigh 3.0992g ZrOCl 2 ·8H 2 O, 0.0677g Y 2 o 3 and 0.0153g Pr 6 o 11 Add excess 1:1 nitric acid and heat to dissolve Y 2 o 3 and Pr 6 o 11 , to form a clear solution of yttrium nitrate and praseodymium nitrate, the weighed ZrOCl 2 ·8H 2 O is completely dissolved in it to obtain a mixed salt solution of the metal contained in the target product, and then add 1.7532g NaCl and 1.7009g glycine to the solution, heat and dissolve completely, then concentrate the mixed solution until viscous, and put it into the set temperature It is ignited in a chamber with a constant temperature of 500°C. After the combustion is completed, the sample is taken out, washed, filtered, and dried to obtain a specific surface area of 127 m 2 g -1 of (Pr 6 o 11 ) 0.0015 (Y 2 o 3 ) 0.015 (ZrO 2 ) 0.961 Pale yellow powder.

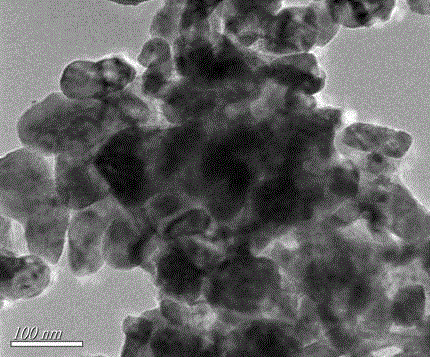

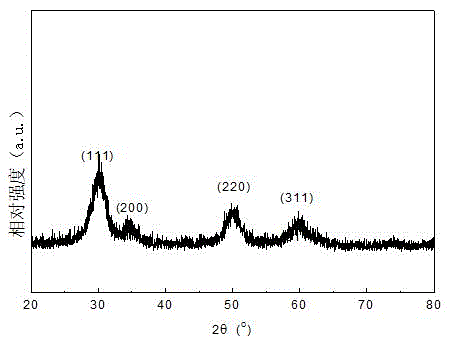

Embodiment 3

[0029] Weigh 2.9831g ZrOCl 2 ·8H 2 O, 0.0677g Y 2 o 3 and 0.0255g Pr 6 o 11 Add excess 1:1 nitric acid and heat to dissolve Y 2 o 3 and Pr 6 o 11 , to form a clear solution of yttrium nitrate and praseodymium nitrate, the weighed ZrOCl 2 ·8H 2 O is completely dissolved in it to obtain the mixed salt solution of the metal contained in the target product, then add 2.2365 g KCl and 0.5193 g urea to the solution, heat and dissolve completely, then concentrate the mixed solution to a viscous state, and put it into the set temperature It is ignited in a chamber with a constant temperature of 500°C. After the combustion is completed, the sample is taken out, washed, filtered, and dried to obtain a specific surface area of 318 m 2 g -1 of (Pr 6 o 11 ) 0.0025 (Y 2 o 3 ) 0.03 (ZrO 2 ) 0.925 Pale yellow powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com