A strain for producing medium and low temperature β-mannanase and its application

A technology of mannanase and low temperature, which is applied in the field of microorganisms, can solve the problems of cost limitation on the application scale of β-mannanase, and achieve the effect of meeting the needs of oil field fracturing engineering, wide temperature tolerance range and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Isolation and Identification of Example 1 Strain OPUS-001

[0050] 1. Isolation of strain OPUS-001

[0051] (1) Sample collection: from the root soil of plants on the banks of Hongjiannao Lake in Shenmu County, Shaanxi Province;

[0052] (2) Heat treatment: the soil sample was made into a suspension with sterile deionized water, and heat treated at 80°C for 10 minutes to kill the bacteria;

[0053] (3) Enrichment culture: add nutrient sources to the heat-treated suspension, and culture at 37°C for 2 days to obtain enriched spore-forming bacteria;

[0054] (4) Separation and purification: gradiently dilute the enriched cultured microbial culture solution, and select a dilution factor of 10 -5 、10 -6 and 10 -7 The three gradients were streaked on solid medium and incubated overnight at 37°C. Pick a single colony and transfer it to the seed medium, and culture it with shaking at 37°C for 1 day to become the seed solution;

[0055] (5) Introduce the seed liquid into t...

Embodiment 2

[0061] The fermentation of embodiment 2OPUS-001 strain

[0062] Inoculate the OPUS-001 strain on the guar gum solid medium and culture it at 37°C for 2 days; inoculate a single colony of the solid medium into the seed medium with a volume ratio of 1 / 5-1 / 4, and incubate at 37°C Cultivate with shaking at 150 rpm for 1 day at °C to become a seed liquid; add the seed liquid to the fermentation medium at a volume ratio of 1 / 50, and culture at 37 °C for 3 days to obtain a fermentation liquid.

Embodiment 3

[0063] The separation and purification of embodiment 3β-mannanase

[0064] Use the following method to separate and purify the β-mannanase in the fermentation broth of OPUS-001 strain:

[0065] (1) Centrifuge the fermentation broth of Example 1 at 3000 rpm and 4°C for 15 minutes, take the supernatant, and filter to obtain a crude extract;

[0066] (2) Add 10 times the amount of 45-65% saturated ammonium sulfate to the crude extract, put the solution on a magnetic stirrer at 4°C overnight; centrifuge at 20,000rpm and 4°C for 30min, keep the supernatant; Add saturated ammonium sulfate to 0.5:1 (v / v), centrifuge again to obtain a precipitate; dissolve the precipitate in PBS, dialyze with PBS solution to remove ammonium sulfate, and obtain a dialysis enzyme solution;

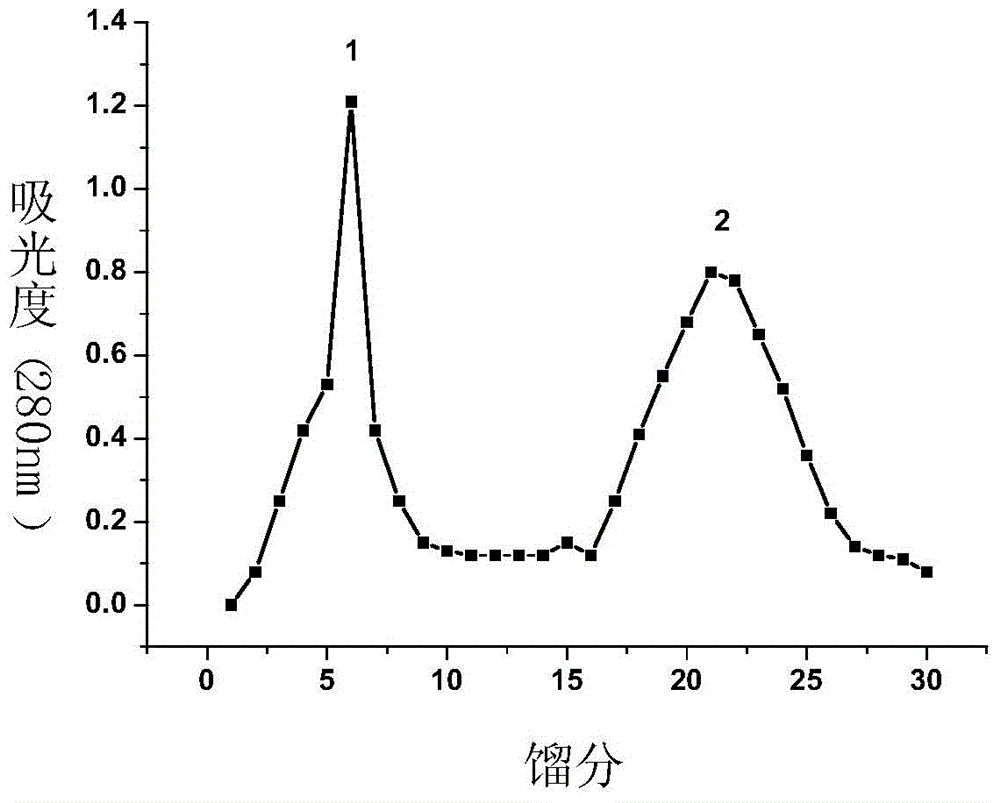

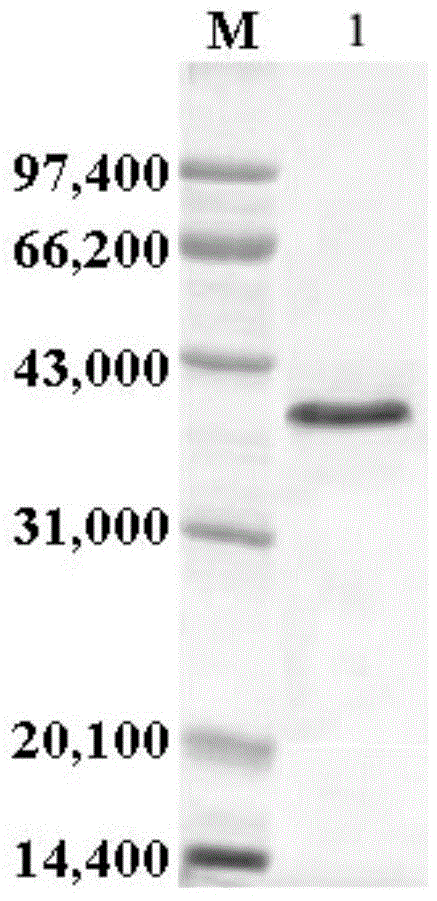

[0067] (3) The dialysis enzyme solution in step (2) was separated by Sepharose G-75 column chromatography, and after loading the sample was eluted with 0.1M NaCl aqueous solution, and the eluate was collected, each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com