Preparation method of styrene-divinylbenzene-carbon nanometer tube copolymerization chromatograph packing material

A technology of divinylbenzene and carbon nanotubes, which is applied in the direction of microsphere preparation, chemical instruments and methods, microcapsule preparations, etc., can solve the problems affecting the overall properties of chromatographic packing, limited doping amount, and insufficient stability of carbon nanotubes , to achieve the effect of strong tolerance, large doping amount and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

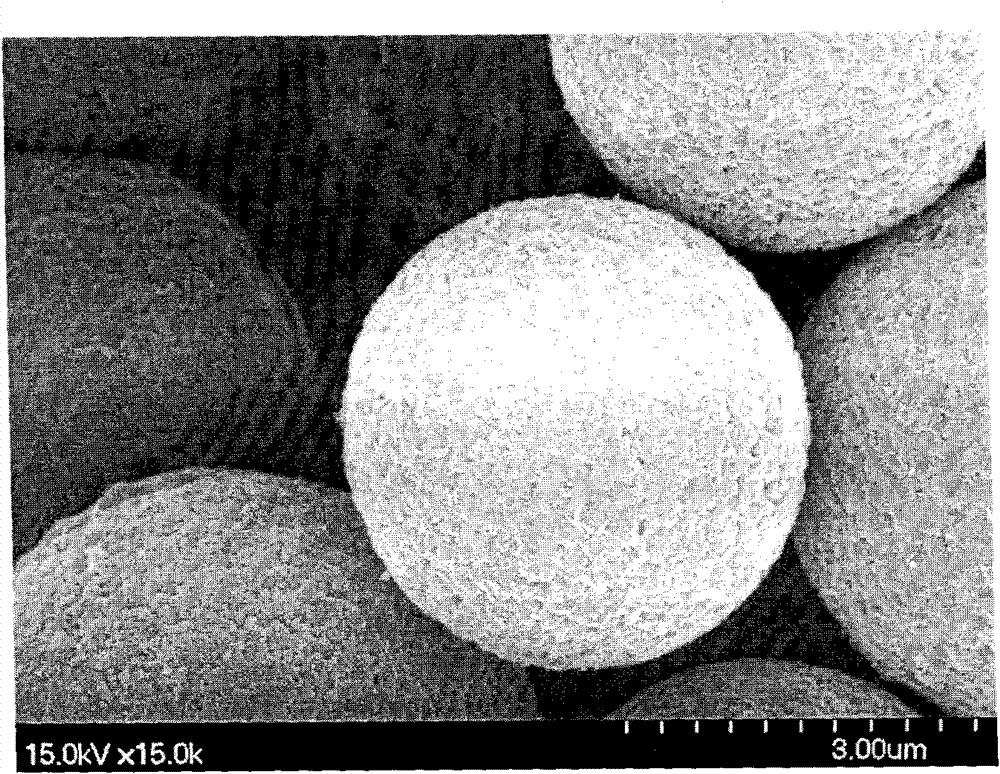

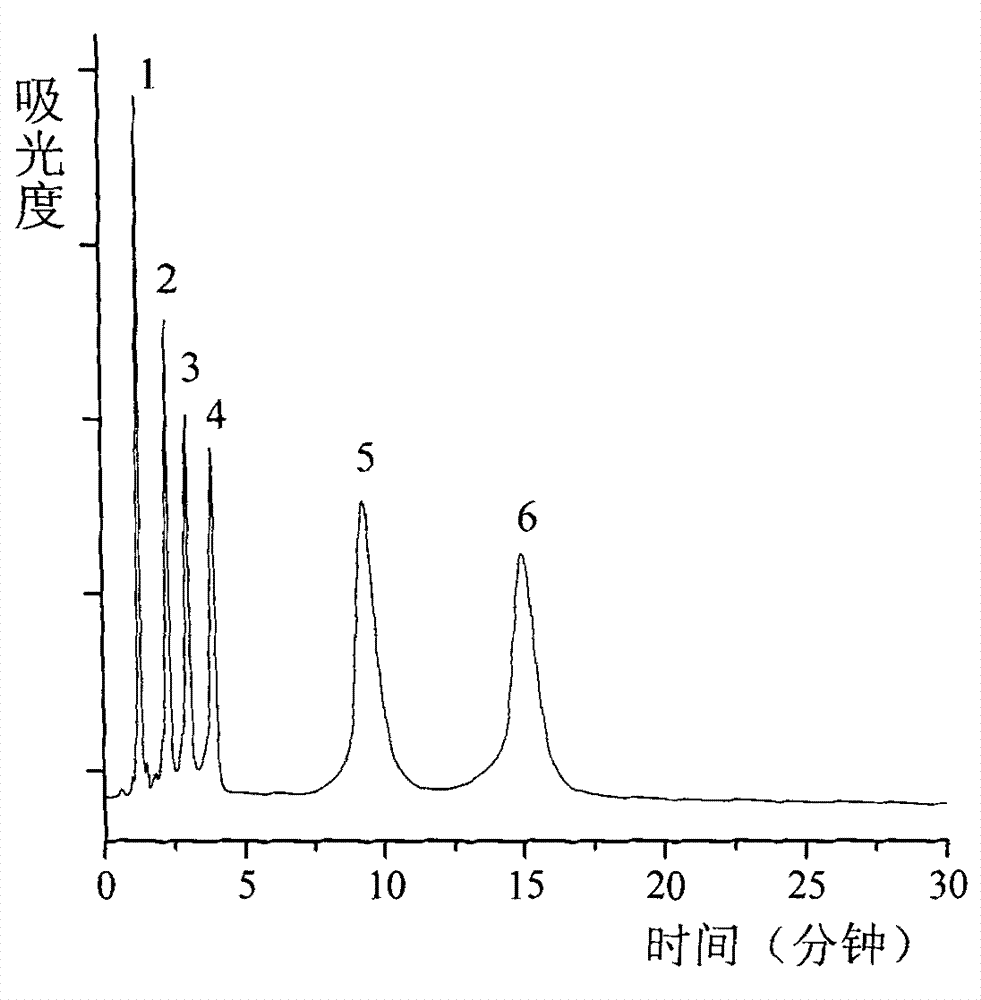

[0026] The manufacturing process of the styrene-divinylbenzene-carbon nanotube copolymer chromatography filler is as follows, and the steps are:

[0027] 1. First, synthesize monodisperse polystyrene seeds with a particle size of 0.8-3 μm by dispersion polymerization method, the concentration of monomer styrene is 5-40% (m / m) of the total amount, and the amount of stabilizer polyvinylpyrrolidone is the amount of the reaction medium. 0.5~4% (g / 100mL), the dosage of initiator azobisisobutyronitrile is 0.5~5% (m / m) of the monomer dosage, the reaction medium is ethanol aqueous solution, the concentration is 70~95% (v / v ), the reaction temperature is 50-75°C, the stirring speed is 150-400 rpm, and the reaction time is 8-24 hours.

[0028] 2. Secondly, the multi-walled carbon nanotubes are reacted with allyl alcohol to couple the double bonds by the method of esterification. The dosage of multi-walled carbon nanotubes is 50-500 mg, dispersed in 100-300 mL of concentrated sulfuric a...

Embodiment 2

[0034] With reference to the method and steps of Example 1

[0035] 1. Synthesize 1.7 μm monodisperse polystyrene seeds by dispersion polymerization method, the concentration of monomer styrene is 20%, the amount of stabilizer polyvinylpyrrolidone is 2%, the amount of initiator azobisisobutyronitrile is 3%, and the reaction The medium is 90% ethanol aqueous solution, the reaction temperature is 80° C., the stirring speed is 400 rev / min, and the reaction time is 24 hours.

[0036] 2. At the same time, 50 mg of multi-walled carbon nanotubes were treated with 200 mL of mixed acid, ultrasonicated at 35° C. for 8 hours, washed until neutral, and then dried. Add 200 mL of thionyl chloride and reflux at 80°C for 4 hours, remove the solvent, dropwise add 100 mL of allyl alcohol, stir magnetically at 50°C for 6 hours, and wash with water until neutral to obtain esterified multi-walled carbon nanotubes.

[0037] 3. Then, monodispersed polystyrene-divinylbenzene-carbon nanotube composit...

Embodiment 3

[0042] (1) Synthesize 1.8 μm monodisperse polystyrene seeds by dispersion polymerization method, the monomer concentration is 20%, the amount of stabilizer is 1.5%, the amount of initiator is 2%, the reaction medium is 95% ethanol aqueous solution, and the reaction temperature is 70 °C, the stirring speed is 250 rpm, and the reaction time is 24 hours.

[0043] (2) 50 mg of multi-walled carbon nanotubes were oxidized with 200 mL of mixed acid, ultrasonicated at 35° C. for 10 hours, washed until neutral, and then dried. Add 100 mL of thionyl chloride to reflux at 80 °C for 6 hours, remove the solvent, add 150 mL of allyl alcohol dropwise, stir magnetically at 55 °C for 6 hours, and wash with water until neutral to obtain esterified multi-walled carbon nanotubes.

[0044] (3) Then, monodispersed polystyrene-divinylbenzene-carbon nanotube composite microspheres with a cross-linking degree of 55% are prepared by a seed swelling method. The monomer concentration is 10%, the content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com