Production method and equipment for preparing ethanol through CO fermentation

A production method, ethanol technology, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problem that the hydrolyzate is not effectively used, achieve the goals of shortening the production cycle, simple method, and improving the conversion rate of ethanol Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

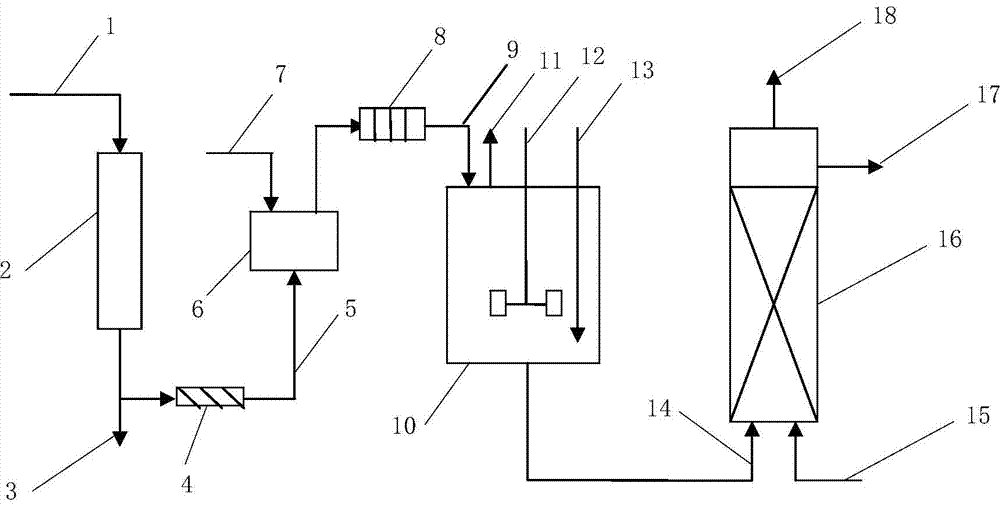

[0034] see figure 1 As shown, lignocellulosic raw materials such as bagasse, sweet sorghum bagasse, etc. are crushed to 40-80 mesh, mixed with water at a mass ratio of 1:20, and placed in hydrolysis reactor 2 for hydrolysis. Reaction conditions: 180°C, 4MPa, 20min (pass N 2maintain pressure). After the reaction, the hydrolyzate is cooled to about 40° C. through the cooler 4 and enters the culture medium storage tank 6 . After the hydrolysis residue is taken out from outlet 3, it can be further enzymatically fermented. Add other medium components to the medium storage tank 6 from the inlet 7 and mix with the hydrolyzate. The prepared culture medium enters the sterilizer 8 and is sterilized at 121° C. for 15 minutes.

[0035] Both the reactor A10 and the reactor B16 are cylinders with the same volume, but the diameter of the reactor B16 is half of the diameter of the reactor A10. Reactor A10 and Reactor B16 were pre-steam sterilized. The sterilized culture medium is passed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com