Method for preparing visual biosensor for detecting organophosphorus pesticides based on ink-jet printing technology

An organophosphorus pesticide and biosensor technology, applied in the field of nano biosensors, can solve the problems of complicated assembly steps, narrow application range, easy inactivation of enzymes, etc., and achieve the effects of controllable sensor structure, high sensitivity and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Gradient dilution of cationic polyelectrolyte solution with deionized water, final mass concentration of 0.007~0.35%, filtration with 0.22 μm filter membrane;

[0019] (2) The newly prepared quantum dot solution is concentrated by centrifugation to remove excess stabilizers and ions in the solution;

[0020] (3) Refit an ordinary office printer into an ink supply system, design different patterns through the corresponding software of the printer, and inject cationic polyelectrolyte solution and quantum dot solution into the cartridge;

[0021] (4) Alternately print and deposit polyelectrolyte and quantum dot solutions on the base material, prepare 10-100 double-layer polyelectrolyte / quantum dot multilayer films, dry at room temperature, and be tested;

[0022] (5) Then, add polyelectrolyte and protein solution alternately on the multilayer film prepared in step (4) to prepare 0-5 double-layer (polyelectrolyte / protein) multilayer films, and finally continue to alternately add...

Embodiment 2

[0028] The difference between this embodiment and embodiment 1 is that in step (5), polyelectrolyte and acetylcholinesterase solution (0.0025~0.5 mg / mL) are alternately added dropwise on the multilayer film prepared in step (4) to prepare 1~ 5 double-layer (polyelectrolyte / acetylcholinesterase) multilayer films.

Embodiment 3

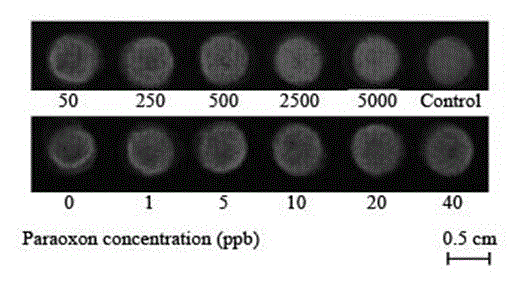

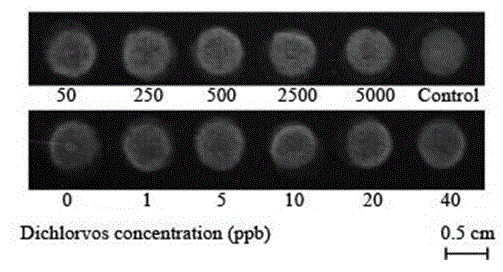

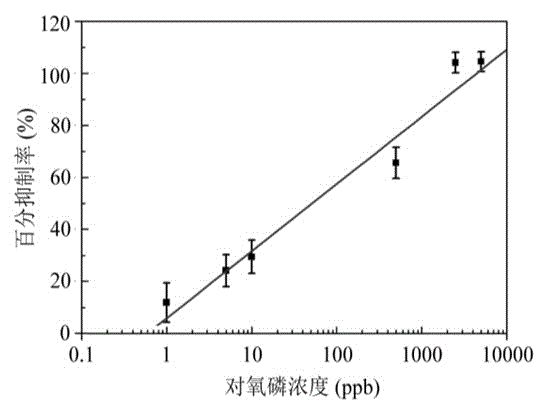

[0030] The polydiallyldimethylammonium hydrochloride (PDDA) solution was diluted with deionized water to a concentration of 0.07%, and then filtered with a 0.22 μm filter membrane; ultrafiltration concentrated the newly prepared CdTe quantum dot solution (the molecular weight cut-off of the ultrafiltration tube was 30 kDa), remove the excess stabilizer and ions in the solution, and the final concentration is 5x10 -4 mol / L quantum dot solution; add the above two solutions to a common office inkjet printer, and then alternately print 25 (PDDA / CdTe) double layers on a filter paper substrate treated with acetone, and dry at room temperature (as required Different patterns can be printed, dot matrix in this example); Then, add 0.07% PDDA and 0.5mg / ml bovine serum albumin (BSA) alternately on the printed array, and deposit 2 (PDDA / BSA) double layers ; Finally, continue to drop 0.07% of PDDA and 0.25mg / ml acetylcholinesterase (AChE), continue to deposit 2 (PDDA / AChE) double layers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com