Preparation method of high-purity casein phosphopeptide

A casein phosphopeptide, high-purity technology, applied in the field of preparation of high-purity casein phosphopeptide, can solve the problems of low yield and content of casein phosphopeptide, low reaction temperature, low equipment requirements, etc., and achieve low cost, Good water solubility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

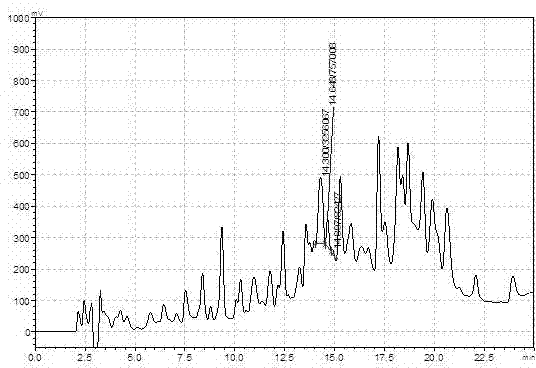

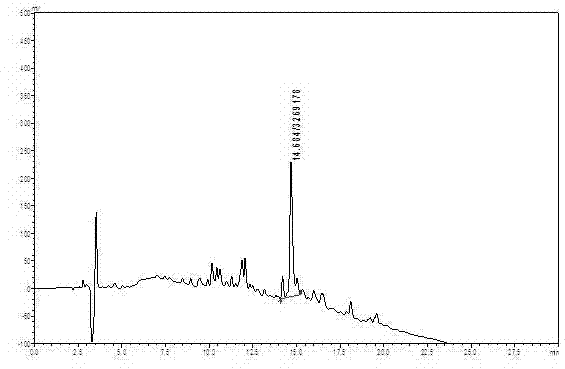

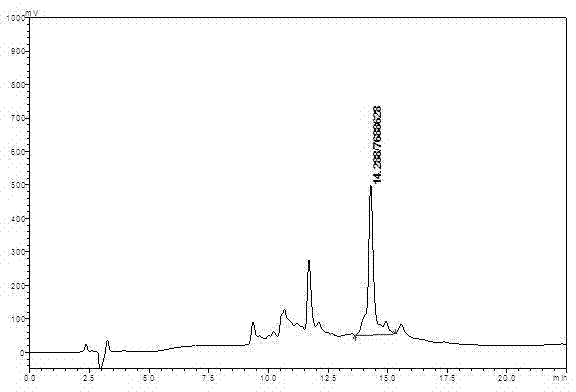

Image

Examples

Embodiment 1

[0021] Example 1 : a kind of preparation of high-purity casein phosphopeptide, comprises the following steps:

[0022] Add 150L of pure water to the reaction kettle, start stirring at 200rpm, heat to 50°C, slowly put 25Kg of casein into the reaction kettle, and adjust the pH to 7.8; put in trypsin: neutral protease: alkaline protease: chymotrypsin = 12.5g of compound protease made by mixing 4:3:2:1 (mass ratio). After 1 hour of enzymatic hydrolysis, the temperature of the feed solution was lowered to 37°C, the pH was adjusted to 4.0, 12.5 g of pepsin was added, and the enzymatic hydrolysis was continued, and the enzymatic hydrolysis ended after 1 hour. Adjust the pH to 4.5 to inactivate the enzyme, adjust the temperature to 90°C, and incubate for 20 min. Use 732 cation exchange resin to absorb and purify for 1 h, filter, adjust the pH of the purified solution to 7.0 with the filtrate, use 717 anion exchange resin to purify for 1 h, wash with water first, discard the washing...

Embodiment 2

[0023] Example 2 : a kind of preparation of high-purity casein phosphopeptide, comprises the following steps:

[0024] Add 200L of pure water to the reaction kettle, stir at 200rpm, heat to 45°C, slowly put 25Kg of casein into the reaction kettle, adjust the pH to 7.5; put in trypsin: neutral protease: papain: chymotrypsin = 3 : 25g of complex protease made by mixing 2:4:1. After 1.5 hours of enzymatic hydrolysis, the temperature of the feed liquid was lowered to 40°C, the pH was adjusted to 5, 25g of pepsin was added, and the enzymatic hydrolysis was continued, and the enzymatic hydrolysis was completed after 1 hour. Adjust the pH to 4.6, adjust the temperature to 80°C, and incubate for 30 min to inactivate the enzyme. Filter to remove unenzymolyzed casein and other macromolecular protein precipitates, use 001×7 cation exchange resin to absorb and purify the supernatant for 1 hour, filter, adjust the pH of the purified solution to 6.5 with the filtrate, and use American Am...

Embodiment 3

[0025] Example 3 : a kind of preparation of high-purity casein phosphopeptide, comprises the following steps:

[0026] Add 250L of pure water to the reaction kettle, stir at 200rpm, heat to 45°C, slowly put 25Kg of casein into the reaction kettle, and adjust the pH to 8.5; put in trypsin:alkaline protease:papain:neutral protease=2 : 50g of compound protease made by mixing 3:1:4. After 2 hours of enzymatic hydrolysis, the temperature of the feed solution was lowered to 37°C, the pH was adjusted to 4.5, 12.5 g of pepsin was added, and the enzymatic hydrolysis was continued, and the enzymatic hydrolysis ended after 1 hour. Adjust the pH to 4.7, adjust the temperature to 85°C, incubate for 30 min, and inactivate the enzyme. Filter to remove unenzymolyzed casein and other macromolecular protein precipitates, use Rohm and Haas AMBERJET UP6040 cation exchange resin to absorb and purify the supernatant for 1 hour, filter, adjust the pH of the purified solution to 7.0 with the filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com