Plastic weaving bag production process

A plastic woven bag and production process technology, which is applied in the field of packaging materials, can solve the problems of high cost, insufficient rigidity, toughness, and room temperature stability of plastic woven bags, and consume a large amount of electric energy, so as to achieve less winding, change room temperature stability, and save energy. The effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Raw material ratio: polypropylene resin PP T30S: 54%, polypropylene resin PP 045: 29%, nano calcium carbonate filler masterbatch: 17%;

[0020] 2. Mixing: Weigh 125kg of raw materials prepared in step (1), mix them with a high-speed mixer, and then dry them. The drying temperature is controlled at 95°C and the drying time is controlled at 18 minutes;

[0021] 3. Wire drawing: feed the raw material prepared in step (2) into the extruder, and after the heating of the barrel and the mutual shearing action between the screw and the barrel, it becomes molten in an almost completely plasticized state. The temperature is controlled at 220°C, and it is formed and extruded into a film through a die head. The traction ratio is controlled to be 1:5, and then it is cooled by water, and the water temperature is controlled at 48°C. , the draft ratio is controlled to be 5, and the flat yarn shrinks at a low traction speed after heat setting, and the retraction ratio is controlled t...

Embodiment 2

[0026] Example 2: The rest are the same as in Example 1, except that in the step (2), the drying temperature is 98°C and the drying time is 20 minutes; in the step (3), the heating temperature is 230°C, the water temperature is 50°C, and the The reduction ratio is 0.97.

Embodiment 3

[0027] Example 3: The rest is the same as Example 1, the difference is that in the step (2), the drying temperature is 101°C, and the drying time is 22min; in the step (3), the heating temperature is 240°C, and the water temperature The temperature is 52°C, and the shrinkage ratio is 0.99.

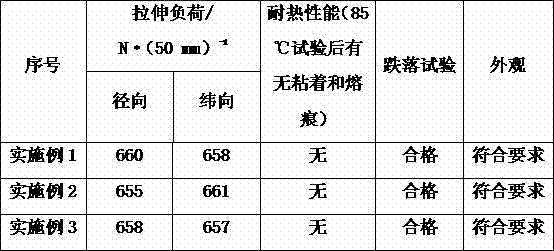

[0028] After the above process steps, take out the plastic woven bag sample, to be tested:

[0029]

[0030] From the above data, it can be seen that the radial and weft tensile loads of the product have reached 650 N (50 mm) -1 All of the above fully meet the standards of GB / T8947-1998, and the heat resistance is good, and the drop test is also all qualified. The mechanical properties of the product meet the requirements, or even better, and the appearance also meets the requirements. There are no more than 2 broken threads, and there are no broken needles, thread breaks, unsewn curls, insufficient composite width, obvious shedding, air holes, or hard lumps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com