Method for changing crystal morphology of ammonium dihydrogen phosphate by using additive

A technology of ammonium dihydrogen phosphate and additives, which is applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of not improving product purity, reducing fertilizer effectiveness, and incomplete evaporation, so as to reduce mother liquor entrainment and residue, easy to filter and Drying, application value-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

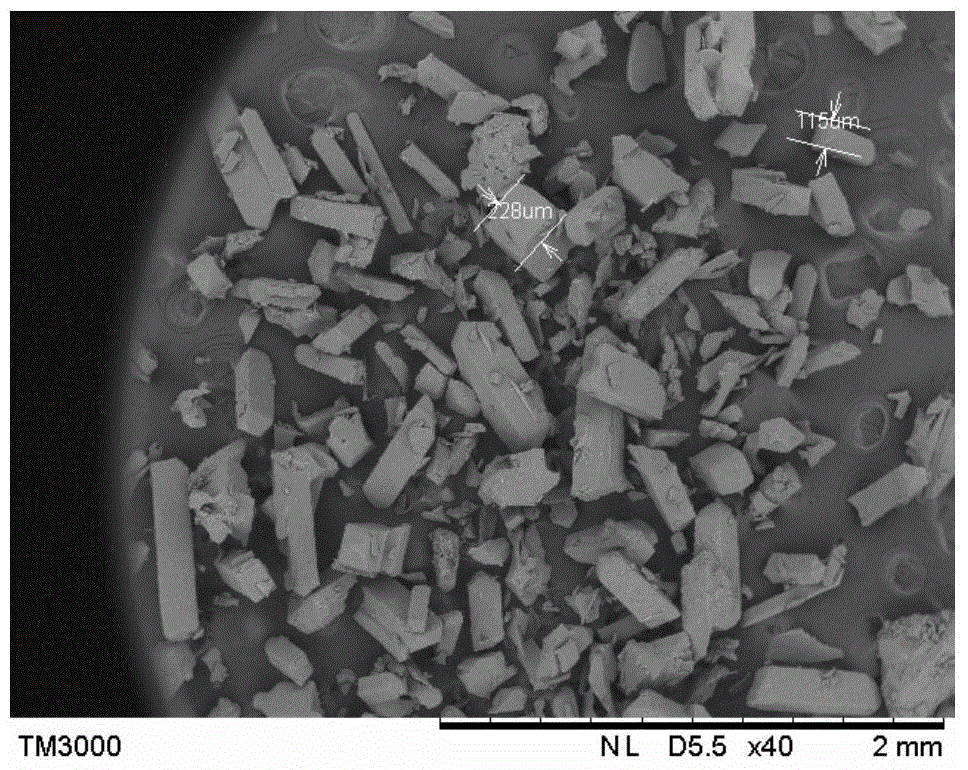

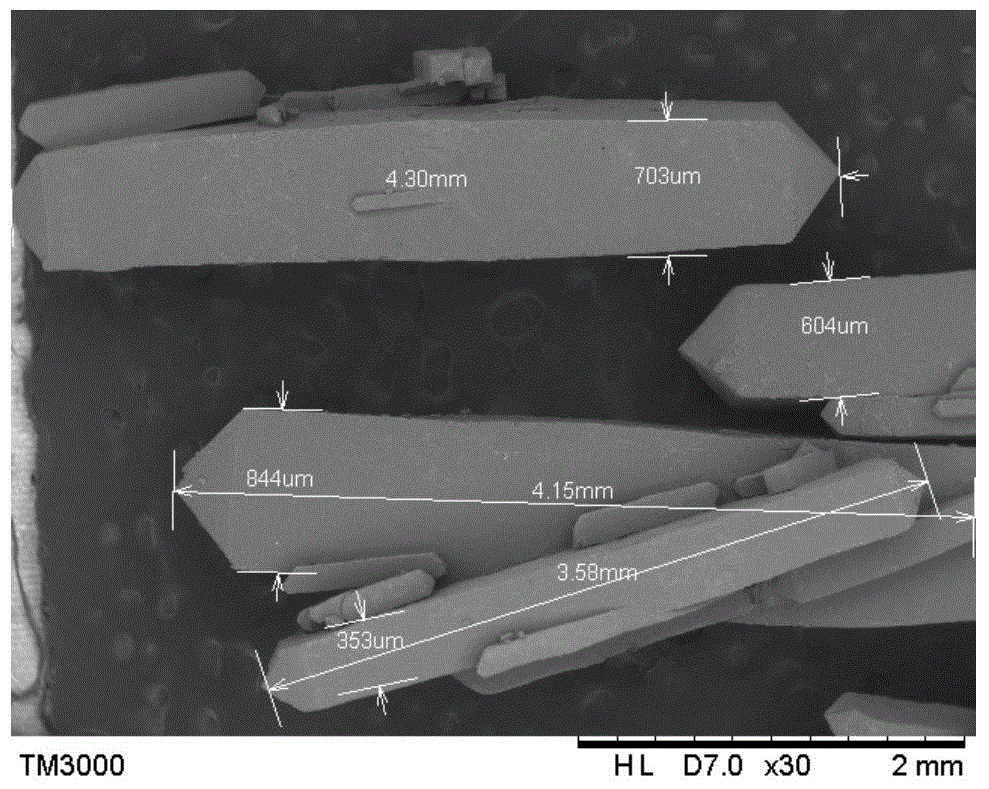

[0022] Take 30g of ammonium dihydrogen phosphate with a purity of 98%, 100g of deionized water, add 500ppm ethylenediaminetetraacetic acid, and stir evenly. The solution was heated to 45°C to dissolve, and the cooling crystallization method was adopted at a cooling rate of 2°C / h, and the temperature was lowered to 5°C. After washing, filtering and drying, rod-shaped ammonium dihydrogen phosphate crystals were obtained. The process quality yield is 35.8%, the product purity reaches 99.9%, the average radial particle size of the crystal is 0.84mm, and the axial particle size is 4.15mm. The electron microscope photo of the product is as follows figure 2 shown.

Embodiment 2

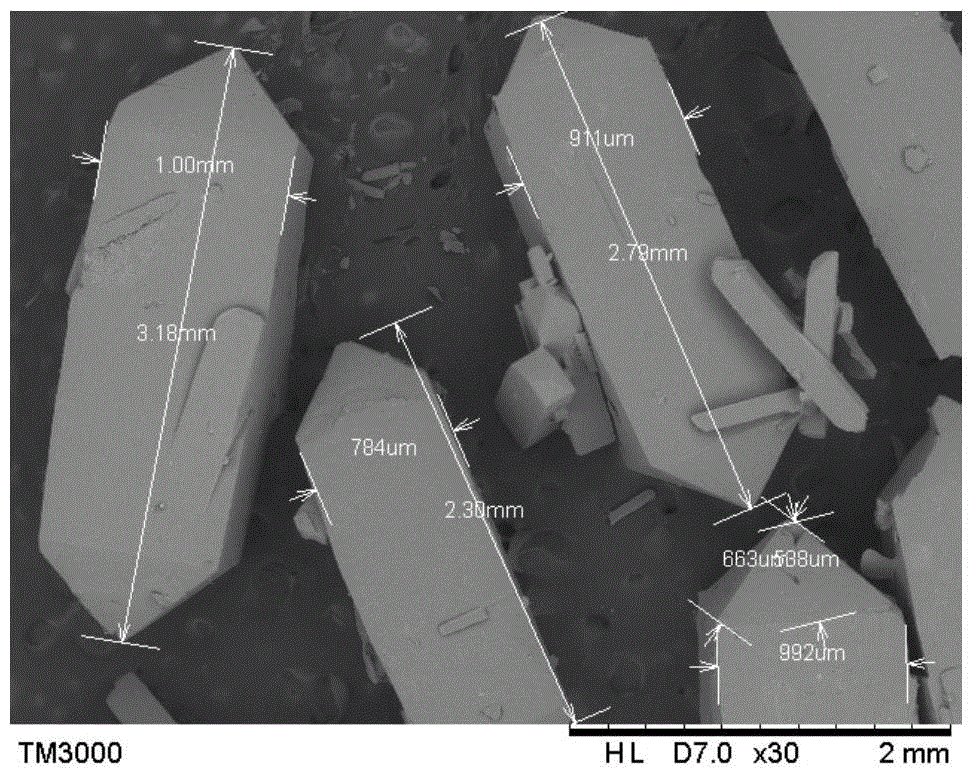

[0024] Take 70g of ammonium dihydrogen phosphate with a purity of 97.2%, 100g of deionized water, add 10000ppm nitrilotriacetic acid, stir evenly, continue to heat the solution to 60°C, and adopt the cooling crystallization method with a cooling rate of 6°C / h to 20°C. After washing, filtering and drying, rod-shaped ammonium dihydrogen phosphate crystals were obtained. The process quality yield is 62.42%, the product purity reaches 99.7%, the average radial particle size of the crystal is 1.00mm, and the axial particle size is 3.18mm. Electron microscope photos of products such as image 3 shown.

Embodiment 3

[0026] Take 60g of ammonium dihydrogen phosphate with a purity of 96%, 100g of deionized water, add 2000ppm succinic acid, and stir evenly. The solution was heated to 58°C to dissolve, and the cooling crystallization method was adopted at a cooling rate of 12°C / h, and the temperature was lowered to 10°C. After washing, filtering and drying, rod-shaped ammonium dihydrogen phosphate crystals were obtained. The process quality yield is 69.13%, the product purity reaches 99.6%, the average radial particle size of the crystal is 0.64mm, and the axial particle size is 4.03mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com