Method for effectively improving Curie temperature of barium titanate-based dielectric material

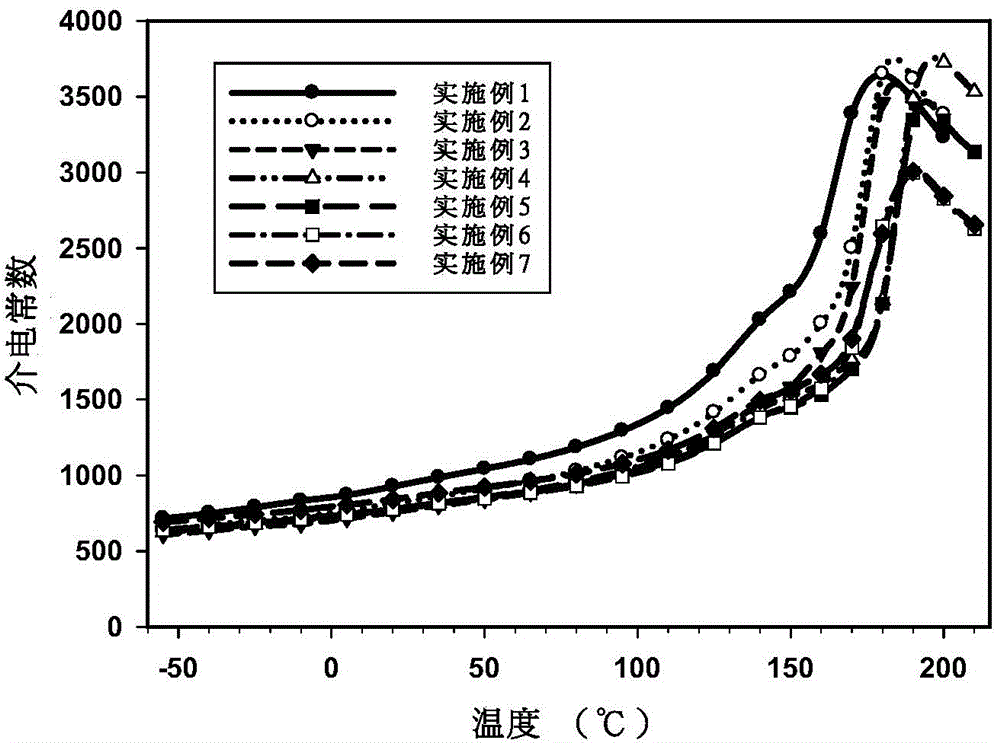

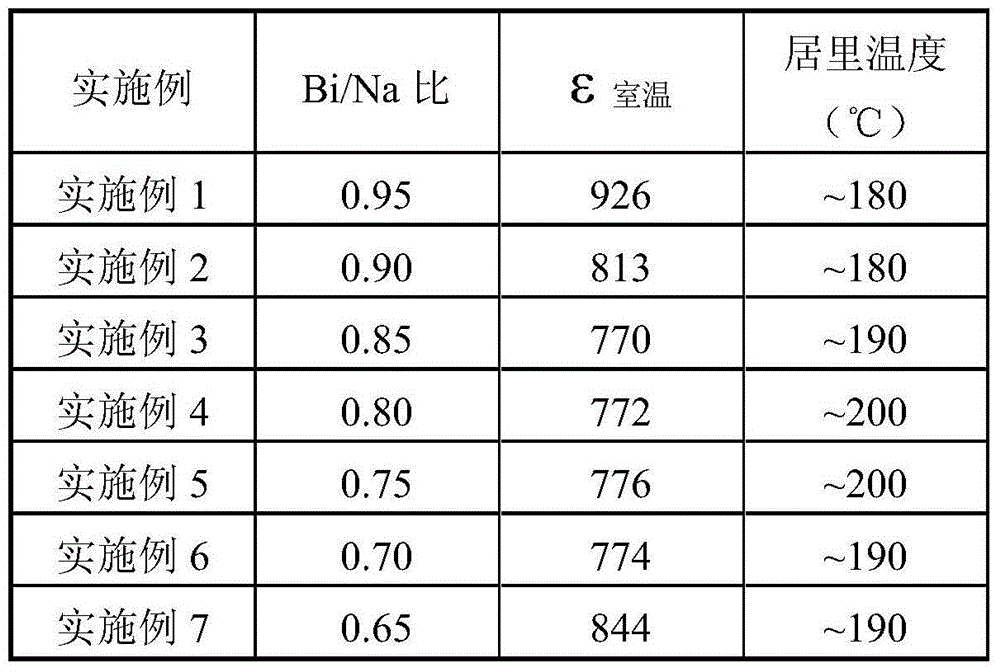

A technology of dielectric material and Curie temperature is applied in the field of effectively increasing the Curie temperature of barium titanate-based dielectric materials, which can solve the problems of inappropriate addition amount and low dielectric constant at room temperature, and achieve the effect of increasing Curie temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 2.5013g Na 2 CO 3 , 7.5393g TiO 2 and 10.4468g Bi 2 o 3 Mix ball milling for 4 hours, dry, sieve, and calcinate at 950°C to obtain sodium bismuth titanate; mix 15g BaTiO 3 Mix 2.4048g sodium bismuth titanate with deionized water and ball mill for 4 hours, add 7% paraffin after drying, sieve and granulate; the powder after granulation is pressed into a green disc, and after 3.5 hours Raise the temperature to 550°C to expel the wax, raise the temperature to 1225°C for 1.5h to sinter, and keep the temperature for 1 hour to prepare the barium titanate-based dielectric material.

[0017] The upper and lower surfaces of the obtained barium titanate-based dielectric material are evenly coated with silver paste, and the electrode is prepared by firing at 850° C. to prepare a multilayer ceramic capacitor. Curie temperature and room temperature dielectric constant of embodiment 1 are shown in table 1.

Embodiment 2

[0019] 2.5013g Na 2 CO 3 , 7.5393g TiO 2 and 9.8970g Bi 2 o 3 Mix ball milling for 4 hours, dry, sieve, and calcinate at 950°C to obtain sodium bismuth titanate; mix 15g BaTiO 3 Mix 2.4048g sodium bismuth titanate with deionized water and ball mill for 4 hours, add 7% paraffin after drying, sieve and granulate; the powder after granulation is pressed into a green disc, and after 3.5 hours Raise the temperature to 550°C to expel the wax, raise the temperature to 1225°C for 1.5h to sinter, and keep the temperature for 1 hour to prepare the barium titanate-based dielectric material.

[0020] The upper and lower surfaces of the obtained barium titanate-based dielectric material are evenly coated with silver paste, and the electrode is prepared by firing at 850° C. to prepare a multilayer ceramic capacitor. Curie temperature and room temperature dielectric constant of embodiment 2 are shown in table 1.

Embodiment 3

[0022] 2.5013g Na 2 CO 3 , 7.5393g TiO 2 and 9.3472g Bi 2 o 3 Mix ball milling for 4 hours, dry, sieve, and calcinate at 950°C to obtain sodium bismuth titanate; mix 15g BaTiO 3 Mix 2.4048g sodium bismuth titanate with deionized water and ball mill for 4 hours, add 7% paraffin after drying, sieve and granulate; the powder after granulation is pressed into a green disc, and after 3.5 hours Raise the temperature to 550°C to expel the wax, raise the temperature to 1225°C for 1.5h to sinter, and keep the temperature for 1 hour to prepare the barium titanate-based dielectric material.

[0023] The upper and lower surfaces of the obtained barium titanate-based dielectric material are evenly coated with silver paste, and the electrode is prepared by firing at 850° C. to prepare a multilayer ceramic capacitor. Curie temperature and room temperature dielectric constant of embodiment 3 are shown in table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com