Special alloy powder for continuous wave fiber laser cladding

A fiber laser and alloy powder technology, which is applied in the field of alloy powder, can solve the problems of shrinkage, low laser absorption rate, shrinkage cavity, etc., and achieve the effect of improved absorption utilization rate and simple and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Percentage by weight: 11% titanium carbide, 3% lanthanum oxide, 6% aluminum oxide, 8% chromium, 3% iridium, 0.1% carbon, 1.2% manganese, and the balance is nickel. A 500g sample was weighed after mechanical mixing, and a nickel-based alloy powder of 200-300 meshes was obtained after sample preparation. Example 2

Embodiment 2

[0020] Percentage by weight: 12% titanium carbide, 2% lanthanum oxide, 5% aluminum oxide, 10% chromium, 2% iridium, 0.15% carbon, 1% manganese, and the balance is nickel. A 500g sample was weighed after mechanical mixing, and a nickel-based alloy powder of 200-300 meshes was obtained after sample preparation.

Embodiment 3

[0022] Percentage by weight: 13% titanium carbide, 5% lanthanum oxide, 7% aluminum oxide, 9% chromium, 4% iridium, 0.2% carbon, 1.1% manganese, and the balance is nickel. A 500g sample was weighed after mechanical mixing, and a nickel-based alloy powder of 200-300 meshes was obtained after sample preparation.

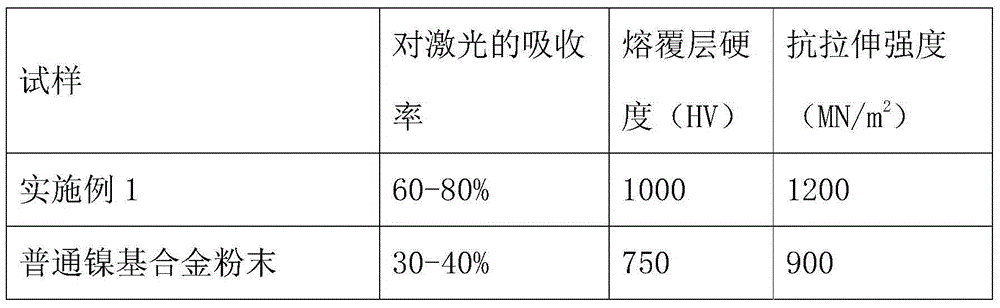

[0023] The nickel base alloy powder that is prepared by embodiment 1, at 3000W continuous fiber laser power, spot size 12mm 2 , scanning speed 20mm / s, powder feeding rate 25g / min and other process conditions, laser cladding treatment was performed on the surface of the workpiece whose base material is No. 45 steel. At room temperature, the test results are shown in the following table:

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com