Microorganism electrochemical denitrification method for enhancing bio-hydrogen production

A microbial electrochemical and microbial technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of catholyte pH rise, low cathode denitrification rate, alkalinity consumption, etc. problems, to achieve the effect of increasing the denitrification rate, increasing the reduction rate and denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Using the sludge of Wuxi Chengbei Sewage Treatment Plant to carry out biological hydrogen production enhanced microbial electrochemical denitrification

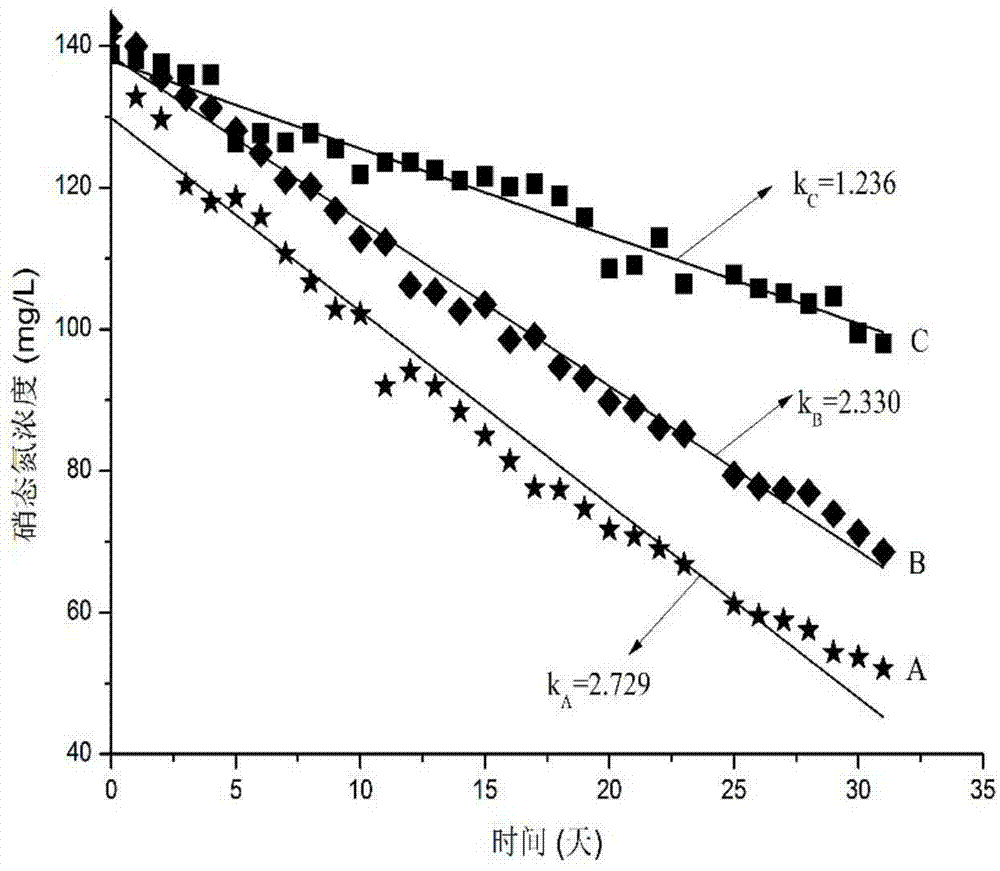

[0018] combined with figure 1 , 2 described as follows:

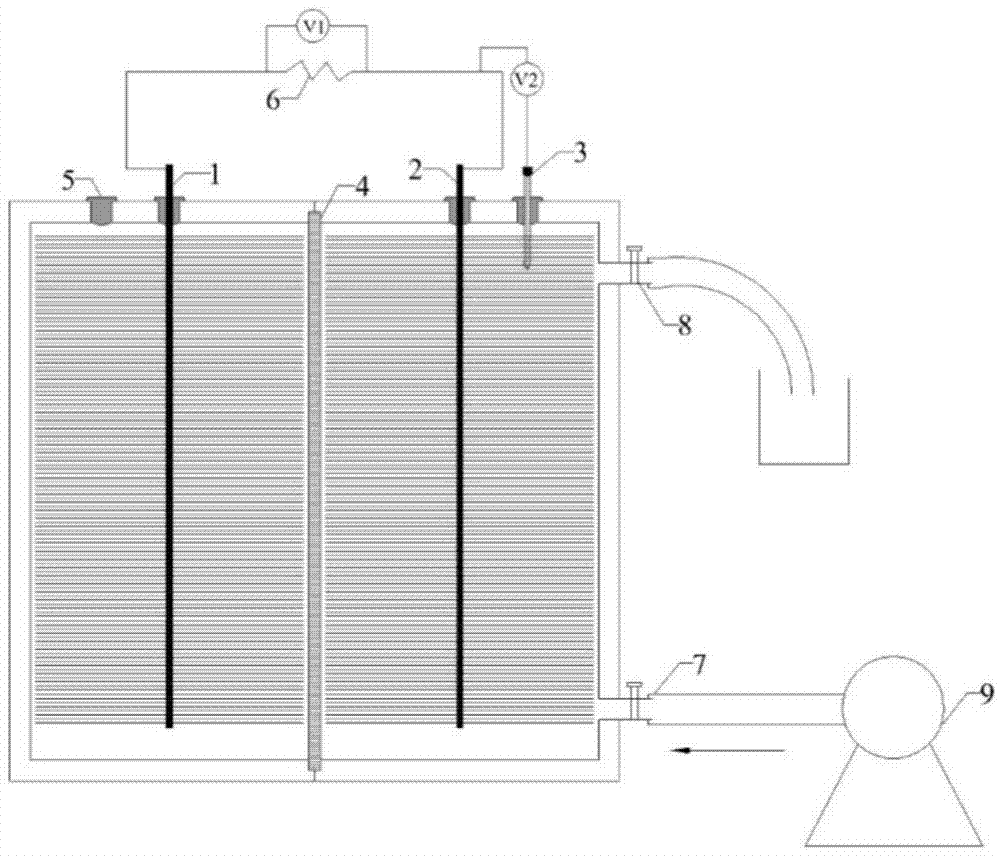

[0019] Such as figure 1 As shown, the present invention uses a microbial electrochemical system as a reactor, which is composed of an anode chamber and an anode chamber, separated by a cation exchange membrane in the middle. The anode is fed by the water inlet (5), the cathode is fed by the water inlet (7) with a peristaltic pump, and the sample is taken through the water outlet (8). )superior.

[0020] First, a total volume of 550mL electrogenic nutrient solution and anaerobic sludge supernatant acclimated by electrogenic nutrient solution were inoculated into the anode chamber, wherein electrogenic nutrient solution and anaerobic sludge supernatant (containing electrogenic nutrient solution) microorganisms) with a volume ratio of 3:1, and the an...

Embodiment 2

[0021] Example 2 Using the sludge from Xuzhou Kangdafeng County Sewage Treatment Plant to carry out biological hydrogen production enhanced microbial electrochemical denitrification

[0022] The implementation method in Example 2 is similar to that of Example 1, except that the anaerobic sludge of electricity-producing microorganisms, denitrifying microorganisms and hydrogen-producing microorganisms are all obtained from Xuzhou Kangdafeng County Wastewater Treatment Plant. In addition to the experimental group in which denitrification microorganisms and hydrogen-producing microorganisms were added at the same time, there were also abiotic cathode groups in which only denitrification microorganisms were added and no microorganisms were added. After 32 days of operation, the denitrification effect of the biocathode was significantly improved compared with that of the non-biocathode, and the result was similar to that of Example 1, so no additional charts will be made here.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com