A kind of polyimide/fluorinated graphene composite film and preparation method thereof

A technology of fluorinated graphene and polyimide, which is applied in the field of chemical materials, can solve problems such as insoluble and infusible, large dielectric loss, and deep color of polyimide film, so as to improve optical and mechanical properties, The effect of good dielectric properties and strong application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

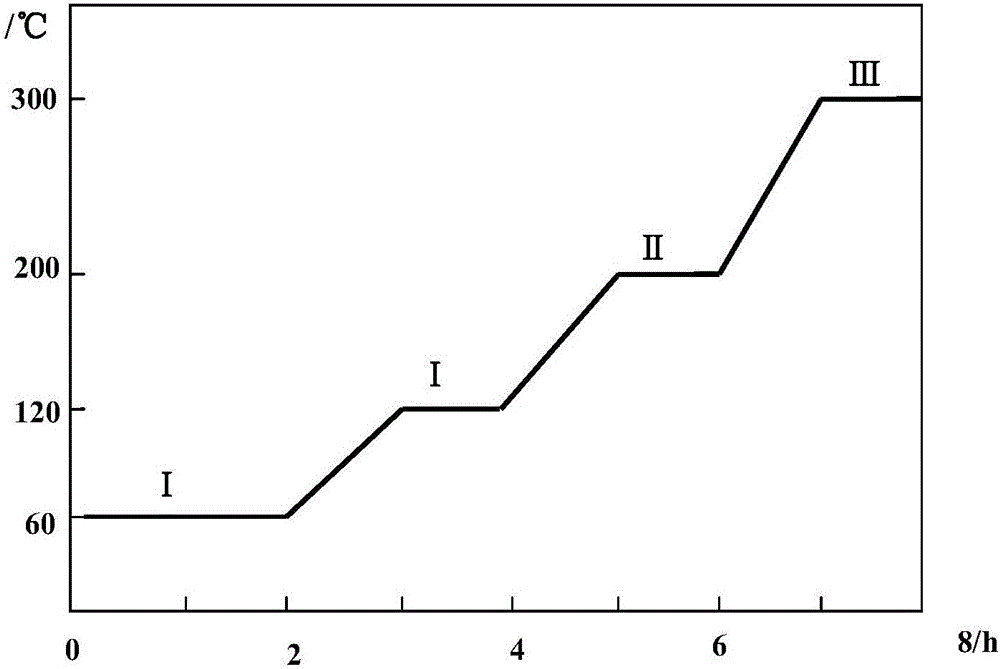

[0021] The preparation of embodiment 1 polyimide / fluorinated graphene composite film

[0022] 1. Preparation of fluorinated graphene

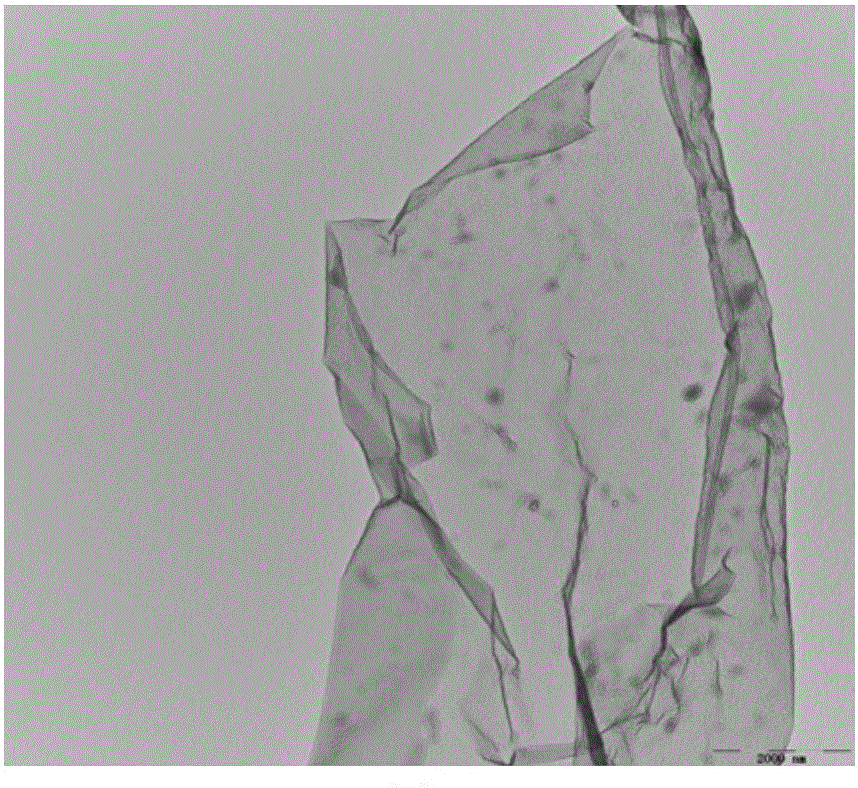

[0023] A certain amount of fluorinated graphite was weighed into a three-necked flask, and an appropriate amount of N-methylpyrrolidone (NMP) was added to prepare a solution with a concentration of 5 mg / ml. Heating at 60°C and condensing to reflux for 2 hours, so that NMP, as an intercalation agent, has enough energy to intercalate into the fluorinated graphite sheet. After cooling the solution to room temperature, it was sonicated. Due to the weak interlayer force of fluorinated graphite, excessive ultrasonic power and too long ultrasonic time will cause certain damage to the sheets. Therefore, we use ultrasonic power 300W for 3 hours. Finally, it was centrifuged (500r / min, 1h) to take the supernatant to remove the precipitate (unexfoliated graphite fluoride), so as to obtain a relatively complete single-layer fluorinated graphene. Transmis...

Embodiment 2

[0033] The test of embodiment 2 polyimide / fluorinated graphene composite film properties

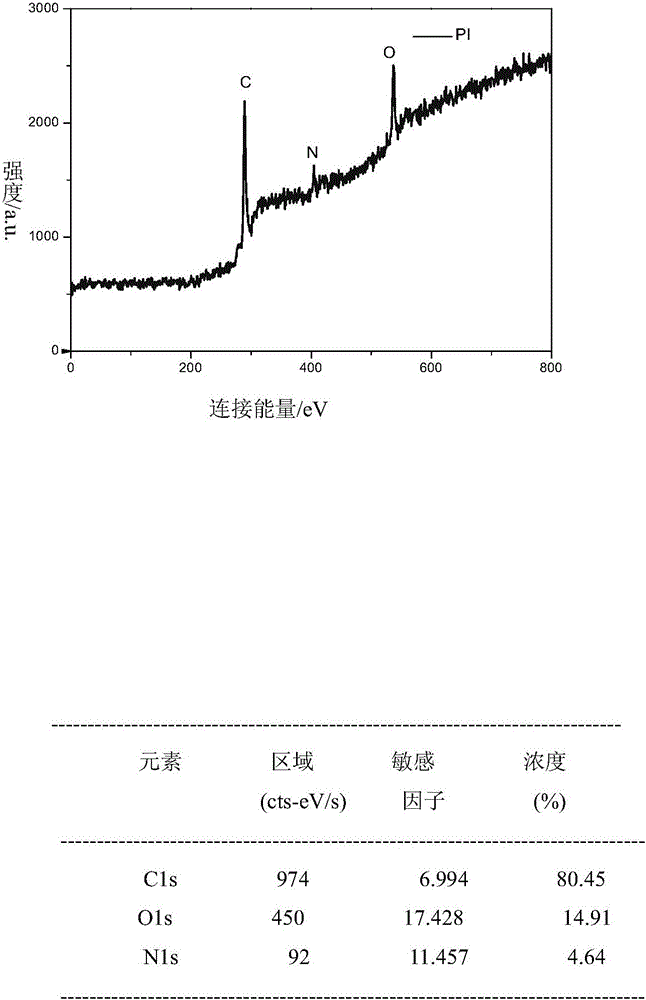

[0034] With pure polyimide film and the fluorinated graphene polyimide composite film that embodiment 1 obtains, cut into 1cm respectively 2 X-ray photoelectron spectrometer is used to analyze the elements on the surface of the film and record the content percentage of each element. The experimental results are shown in image 3 and Figure 4 . Since the monomers for preparing polyimide are formed by dehydration and cyclization of BTDA and ODA, and the raw materials only contain three elements of C, N, and O, image 3 Very consistent with this, it can be seen that the polyimide film has been successfully prepared. and Figure 4Due to the addition of fluorinated graphene, the corresponding peaks of fluorine atoms also appear in the XPS diagram, but its content is less, because the polyimide resin wraps the fluorinated graphene, leaving a small amount of fluorine on the surface result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com