Itraconazole pellet as well as preparation method and preparation thereof

A technology of itraconazole pellets and itraconazole, which is applied in the directions of pill delivery, antifungal agents, pharmaceutical formulations, etc., can solve the problems such as the inability to achieve good efficacy, the inability to guarantee the dissolution effect, and the increase in the dissolution rate. , to achieve the effect of preventing adhesion, rapid dissolution, and stable dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The itraconazole pellets of this embodiment are prepared by sequentially coating the itraconazole drug-containing layer and the isolation protective layer on the surface of the pellet core;

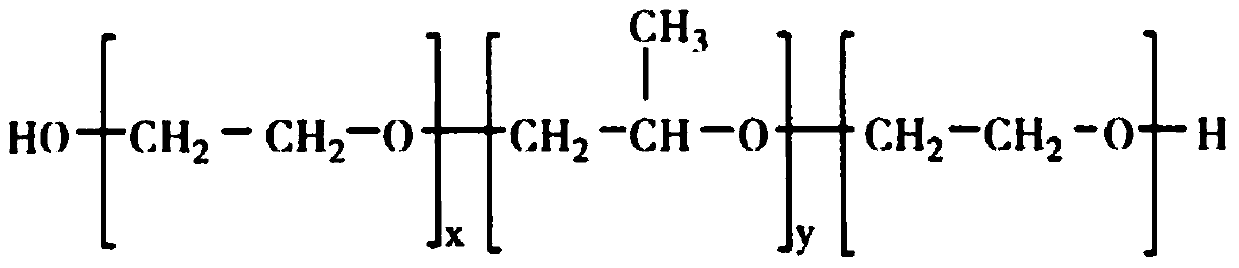

[0046] The itraconazole drug-containing layer is prepared from the following raw material components: 10 parts by weight of itraconazole; a mixture of the polyacrylic acid resin IV and the poloxamer 188 mixed at a weight ratio of 1:0.3 As a solid dispersion, 12 parts by weight; hydroxypropyl methylcellulose is used as a binder, 8 parts by weight; talcum powder is used as an anti-sticking agent, 3 parts by weight; dichloromethane and ethanol mixed at a volume ratio of 0.7:1 The mixture is used as an organic solvent, 150 parts by weight;

[0047] The isolation protection layer is prepared from the following raw material components: polyethylene glycol as a lubricant, 25 parts by weight; ethanol as a dispersion solvent, 80 parts by weight;

[0048] 150 parts by weight of the pellet c...

Embodiment 2

[0056] The itraconazole pellets of this embodiment are prepared by sequentially coating the itraconazole drug-containing layer and the isolation protective layer on the surface of the pellet core;

[0057] The itraconazole drug-containing layer is prepared from the following raw material components: 20 parts by weight of itraconazole; a mixture of the polyacrylic acid resin IV and the poloxamer 188 mixed in a weight ratio of 1:0.7 As a solid dispersion, 7 parts by weight; hydroxypropyl methylcellulose as a binder, 12 parts by weight; talcum powder, 3.5 parts by weight as an anti-sticking agent; dichloromethane and ethanol mixed at a volume ratio of 2:1 The mixture is used as an organic solvent, 70 parts by weight;

[0058] The isolation protective layer is prepared from the following raw material components: polyethylene glycol as a lubricant, 25 parts by weight; ethanol as a dispersion solvent, 75 parts by weight;

[0059] 150 parts by weight of the pellet core with a partic...

Embodiment 3

[0067] The itraconazole pellets of this embodiment are prepared by sequentially coating the itraconazole drug-containing layer and the isolation protective layer on the surface of the pellet core;

[0068] The itraconazole drug-containing layer is prepared from the following raw material components: 30 parts by weight of itraconazole; a mixture of the polyacrylic acid resin IV and the poloxamer 188 mixed in a weight ratio of 1:1.2 As a solid dispersion, 36 parts by weight; hydroxypropyl methylcellulose as a binder, 7 parts by weight; talcum powder, 5 parts by weight as an anti-adhesive agent; 0.7:1 volume ratio of dichloromethane and ethanol mixed The mixture is used as an organic solvent, 300 parts by weight;

[0069] The isolation protective layer is prepared from the following raw material components: polyethylene glycol as a lubricant, 30 parts by weight; ethanol as a dispersion solvent, 60 parts by weight;

[0070] 125 parts by weight of the pellet core with a particle d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com