Method for extracting alpha-amylase inhibitor from white kidney beans by use of microwave-compound enzyme coupling method

An amylase inhibitor and compound enzyme technology, which is applied in the field of alpha-amylase inhibitors, can solve the problems of low purity and activity of alpha-amylase inhibitors, long time consumption, etc., so as to shorten enzymatic hydrolysis time, improve purity, The effect of shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

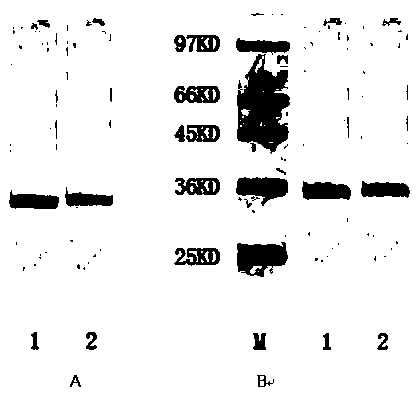

Image

Examples

Embodiment 1

[0027] The method for extracting α-amylase inhibitors from white kidney beans by utilizing the microwave-complex enzyme coupling method provided in this embodiment comprises the following steps:

[0028] crude extraction : Take 1000g of white kidney beans and grind them at low temperature, add water to adjust the pH to 4.5 according to the ratio of 1:15 (mass ratio, the same below), then add 0.6% of the total weight of white kidney beans with glucoamylase and cellulase (glucoamylase: cellulase =10:1, mass ratio, the same below) placed under 700W, 55°C microwave radiation for 30min, wait until the temperature drops to room temperature and adjust its pH value to 6.5, then add papain and lipase of 0.3% of the total weight of white kidney beans (Papain:lipase=2:1, mass ratio, the same below) Place it under 700W, 50°C microwave radiation for 20min, then inactivate the enzymatic solution at 70°C for 30min;

[0029] refined : Centrifuge the filtrate after inactivating the enzyme,...

Embodiment 2

[0034] crude extraction : Take 1000g of white kidney beans and grind them at low temperature, add water at a ratio of 1:20 to adjust the pH to 4.5, then add 0.6% glucoamylase and cellulase (glucoamylase: cellulase = 15:1) and place in a 700W, 55℃ React under microwave radiation for 20 minutes. After the temperature drops to room temperature, adjust the pH value to 6.5, then add 0.3% papain and lipase (papain: lipase = 2:1) and place it under 600W, 50℃ microwave radiation for 30 minutes. , and then inactivate the enzyme at 70°C for 30min;

[0035] refined : Centrifuge the filtrate after inactivating the enzyme, ultrafilter the supernatant with an ultrafiltration membrane, and use CM-cellulose ion column chromatography on the retentate on the membrane, buffer with 0.025mol / L (pH4.5) acetic acid-sodium acetate solution (containing 0-1.0 mol / L NaCl) with an elution flow rate of 1mL / min, gradient elution, to collect the active protein peak, and the active eluate is filtered thr...

Embodiment 3

[0038] crude extraction : Take 1000g of white kidney beans and grind them at low temperature, add water at a ratio of 1:15 to adjust the pH to 4.5, then add 1.0% glucoamylase and cellulase (glucoamylase: cellulase = 18:1) and place in a 700W, 50℃ React under microwave radiation for 30 minutes, wait until the temperature drops to room temperature and adjust the pH value to 6.5, then add 0.3% papain and lipase (papain: lipase = 4:1) and place it under 700W, 55℃ microwave radiation for 30 minutes , and then inactivate the enzyme at 70°C for 30min;

[0039] refined : Centrifuge the filtrate after deactivating the enzyme, ultrafilter the supernatant with an ultrafiltration membrane, and use 0.025mol / L (pH4.5) acetic acid-sodium acetate to filter the retentate on the membrane through Sephadex G-75 gel column chromatography The buffer solution (containing 0-0.3 mol / L NaCl) was eluted at an elution flow rate of 1 mL / min, gradient elution, and the active protein peak was collected....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com