Preparation method of sulfoacid-type cation exchange resin catalyst

A cation exchange and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, fatty acid esterification, etc., can solve the problems of complex process, expensive, strong corrosion, etc., and achieve efficient catalytic esterification reaction , simple preparation process and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Weigh 2.0 g of dry macroporous cross-linked polystyrene-divinylbenzene white balls into a three-necked flask equipped with a stirring and reflux condenser, add 10.0 g of dichloroethane, and swell at 20°C for 2 hours. Add 20.0 g of methanesulfonic acid, and start stirring at a slow speed. Raise the temperature to 85°C and keep it warm for 6.0h; raise the temperature to 100°C and keep it warm for 3.0h to remove dichloroethane by distillation. Cool to room temperature, add 40% methanesulfonic acid to wash, then slowly add deionized water dropwise under stirring, repeatedly wash until neutral, and vacuum dry at 60-120°C to obtain a macroporous sulfonic acid cation exchange resin catalyst.

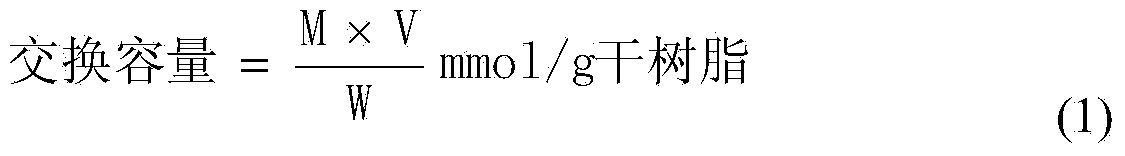

[0013] Calculate the exchange capacity of the catalyst:

[0014]

[0015] in:

[0016] M—concentration of NaOH standard solution (mol / L);

[0017] V—the volume of NaOH standard solution used for titration (mL);

[0018] W—weight of dry resin (g).

[0019] Hydrothermal stability t...

Embodiment 2

[0028] Weigh 2.0 g of dry macroporous cross-linked polystyrene-divinylbenzene white balls, add 4.5 g of dichloroethane, and heat up to 45° C. to swell for 3.0 h. Add 10.0 g of methanesulfonic acid, and start stirring at a slow speed. Raise the temperature to 95°C and keep it warm for 3.0h; raise the temperature to 120°C and keep it warm for 2.0h to remove dichloroethane by distillation. Cool to room temperature, add 80% methanesulfonic acid to wash, then slowly add deionized water dropwise under stirring, repeatedly wash until neutral, and vacuum dry at 60-120°C to obtain a macroporous sulfonic acid cation exchange resin catalyst.

[0029] The exchange capacity of the obtained catalyst and the conversion rate of FFA when used in the esterification reaction are shown in Table 1.

Embodiment 3

[0033] Weigh 2.0 g of dry macroporous cross-linked polystyrene-divinyl benzene white balls into a three-necked flask equipped with a stirring and reflux condenser, add 1.0 g of dichloroethane, and heat up to 80°C to swell for 10 min. Add 40.0 g of methanesulfonic acid, and start stirring at a slow speed. Raise the temperature to 70°C and keep it warm for 1.0h; raise the temperature to 150°C and keep it warm for 0.5h to remove dichloroethane by distillation. Cool to room temperature, add diluted 70% methanesulfonic acid to wash, then slowly add deionized water dropwise under stirring, wash repeatedly until neutral, and vacuum dry at 60-120°C to obtain a macroporous sulfonic acid cation exchange resin catalyst .

[0034] Table 1 shows the exchange capacity of the catalyst and the conversion rate of FFA when used in the esterification reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com