Method for preparing synthesized bone meal for producing bone-china

A technology for synthesizing bone and bone china, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems affecting the dielectric properties and chemical stability of ceramic products, affecting the color after firing, etc., to achieve excellent performance, Effect of small environmental load and stable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Preparation of bone meal precursor

[0026] Calcium hydrogen phosphate (CaHPO 4 2H 2 O) 100.0mol and calcium carbonate (CaCO 3 ) 50.0mol and 22.2Kg of pure water (wherein the ratio of adding water is 100%) join in the ball mill of 100Kg, add the alumina ball stirring bar of 44.5kg at the same time, the size of alumina ball is 15, 30, 45mm, (large, medium and small oxide Aluminum ball ratio is 1: 1: 1), in order to remove impurities such as iron and bleaching in the mixed solution, add 1.0% sodium hypochlorite and 1.5% sodium dithionite respectively, wet pulverize at room temperature for 12 hours, machine speed is 60rmp.

[0027] Step 2: Preparation of Synthetic Bone Meal

[0028] The obtained white emulsion was deironed by physical method and washed 3 times; then it was placed in the natural environment for 4 days to precipitate, and then the supernatant was removed, and the obtained precipitate was dried in a desiccator at 60°C for 5 days.

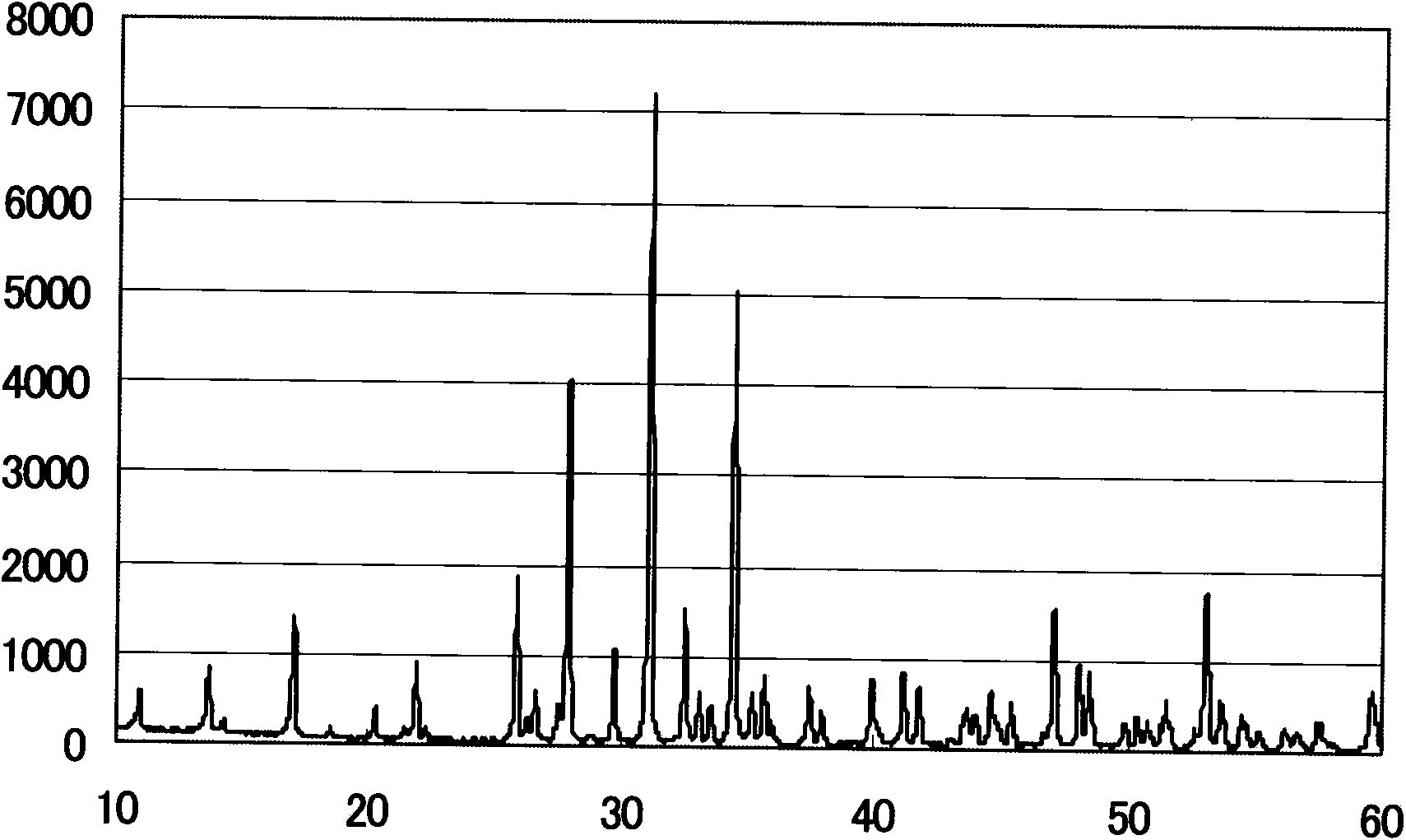

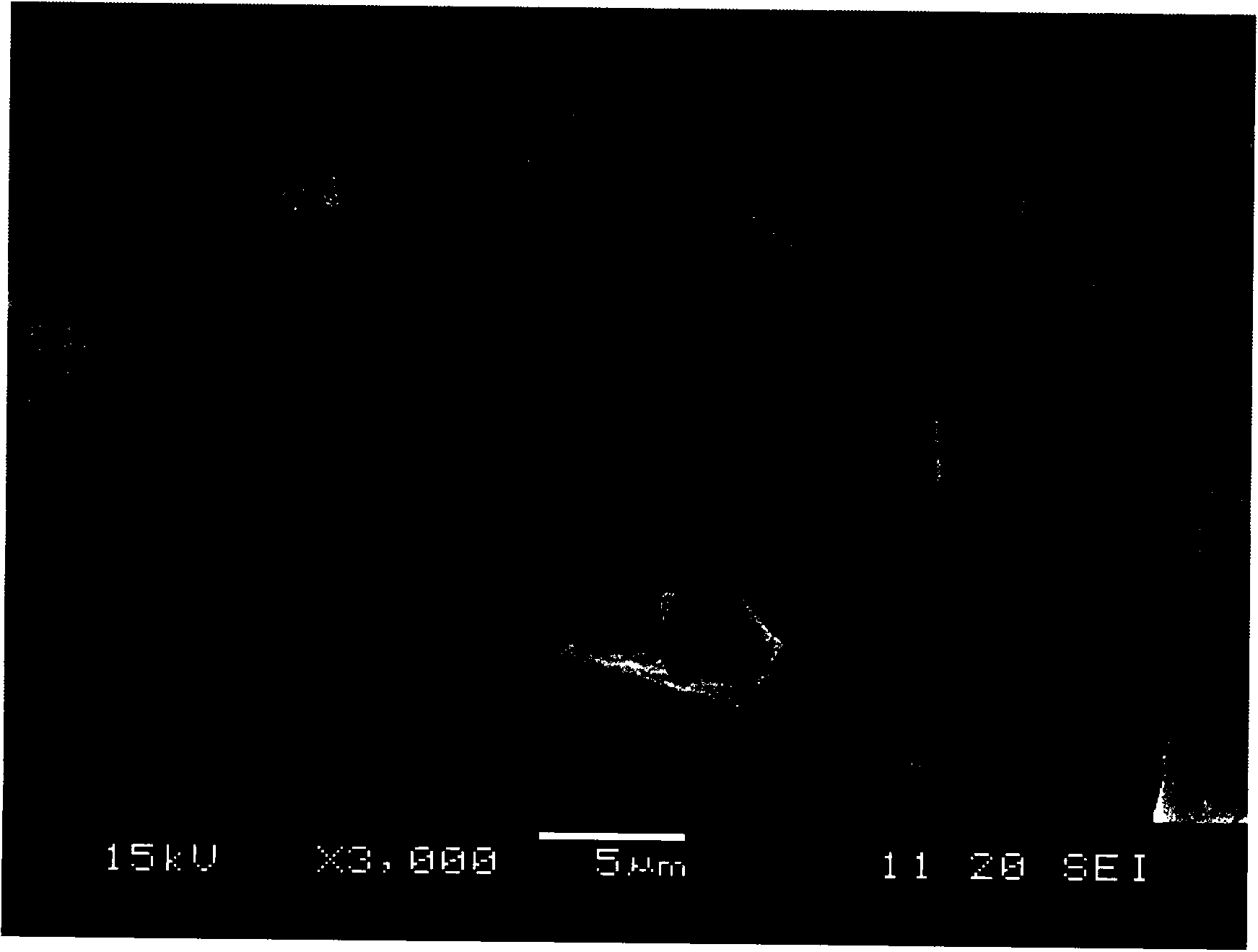

[0029] The drie...

Embodiment 2

[0031] Step 1: Preparation of bone meal precursor

[0032] Calcium hydrogen phosphate (CaHPO 4 2H 2 O) 30.0mol and calcium carbonate (CaCO 3 ) 20.0mol and 10.7Kg pure water (wherein the ratio of adding water is 150%) join in the ball mill of 50Kg, add the alumina ball stirring bar of 14kg at the same time, the size of alumina ball is 20, 40, 60mm, (large, medium and small alumina Ball ratio is 1: 1: 1), in order to remove impurities such as iron and bleaching in the mixed solution, add 2.0% sodium hypochlorite and 1.5% sodium dithionite respectively, wet pulverize at room temperature for 18 hours, machine speed is 50rmp.

[0033] Step 2: Preparation of Synthetic Bone Meal

[0034] The obtained white emulsion was deironed by physical method and washed 3 times; then it was placed in the natural environment for 3 days to precipitate, and then the supernatant was removed, and the obtained precipitate was dried in a dryer at 70°C for 4 days.

[0035] The dried product is calcin...

Embodiment 3

[0037] Step 1: Preparation of bone meal precursor

[0038] Calcium hydrogen phosphate (CaHPO 4 2H 2 O) 25.0mol and calcium carbonate (CaCO 3 ) 15.0mol and 5.8Kg of pure water (wherein the ratio of adding water is 100%) join in the ball mill of 30Kg, add the stirring bar of 11.6kg alumina ball at the same time, the size of alumina ball is 10, 20, 30mm, (large, medium and small oxide Aluminum ball ratio is 1: 1: 1), in order to remove impurities such as iron and bleaching in the mixed solution, add 2.0% sodium hypochlorite and 2.0% sodium dithionite respectively, wet pulverize at room temperature for 24 hours, machine speed is 40rmp.

[0039] Step 2: Preparation of Synthetic Bone Meal

[0040] The obtained white emulsion was iron-removed by physical method and washed three times; then it was placed in the natural environment for 5 days to precipitate, and then the supernatant was removed, and the obtained precipitate was placed in the natural environment to dry.

[0041] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com