Application of cupric borate as visible light catalyst for degrading dye wastewater

A technology for dye wastewater and catalytic degradation, which is applied in the field of photocatalytic treatment, can solve the problems of low utilization rate of visible light, large forbidden band width, etc., and achieves the effect of simple and easy preparation method and strong light degradation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

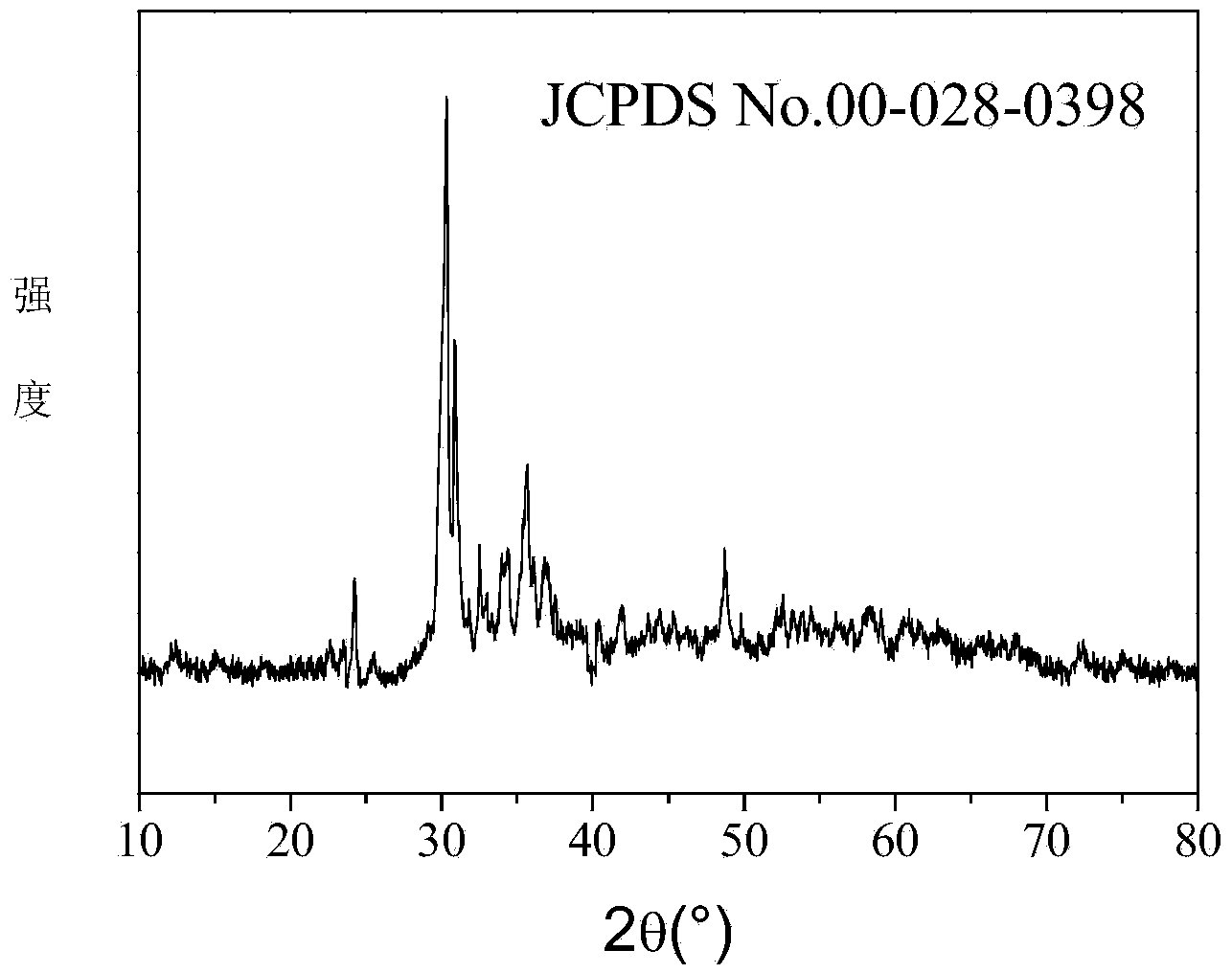

[0031] Weigh 2.5mmol (0.5g) of copper acetate (Cu(CH 3 COO) 2 ·H 2 O), 7.5mmol glucose (1.35g) was dissolved in 20mL distilled water, and magnetically stirred for 2h. Dissolve 2.5mmol (1.55g) of boric acid in 30mL of deionized water, then add the boric acid aqueous solution to the aforementioned reaction solution, and stir magnetically for 2h. Then dry the mixed solution in an oven at 150°C to obtain a brown xerogel, which is then roasted at 850°C for 6 hours to obtain a dark green powder, which is washed with 0.1mol / L hydrochloric acid and deionized water at 60°C respectively 3 to 4 times, centrifuge, and dry the powder at 60°C to obtain Cu 3 B 2 o 6 Single crystal 0.21g. Detected by XRD, as attached figure 1 As shown, the resulting Cu 3 B 2 o 6 It is a pure substance, the corresponding PDF card number: 28-398; tested by SEM, if attached figure 2 As shown, sample Cu 3 B 2 o 6 It is rod-shaped, with a diameter of about 300-600 nm and a length of about 6 μm.

[...

Embodiment 2

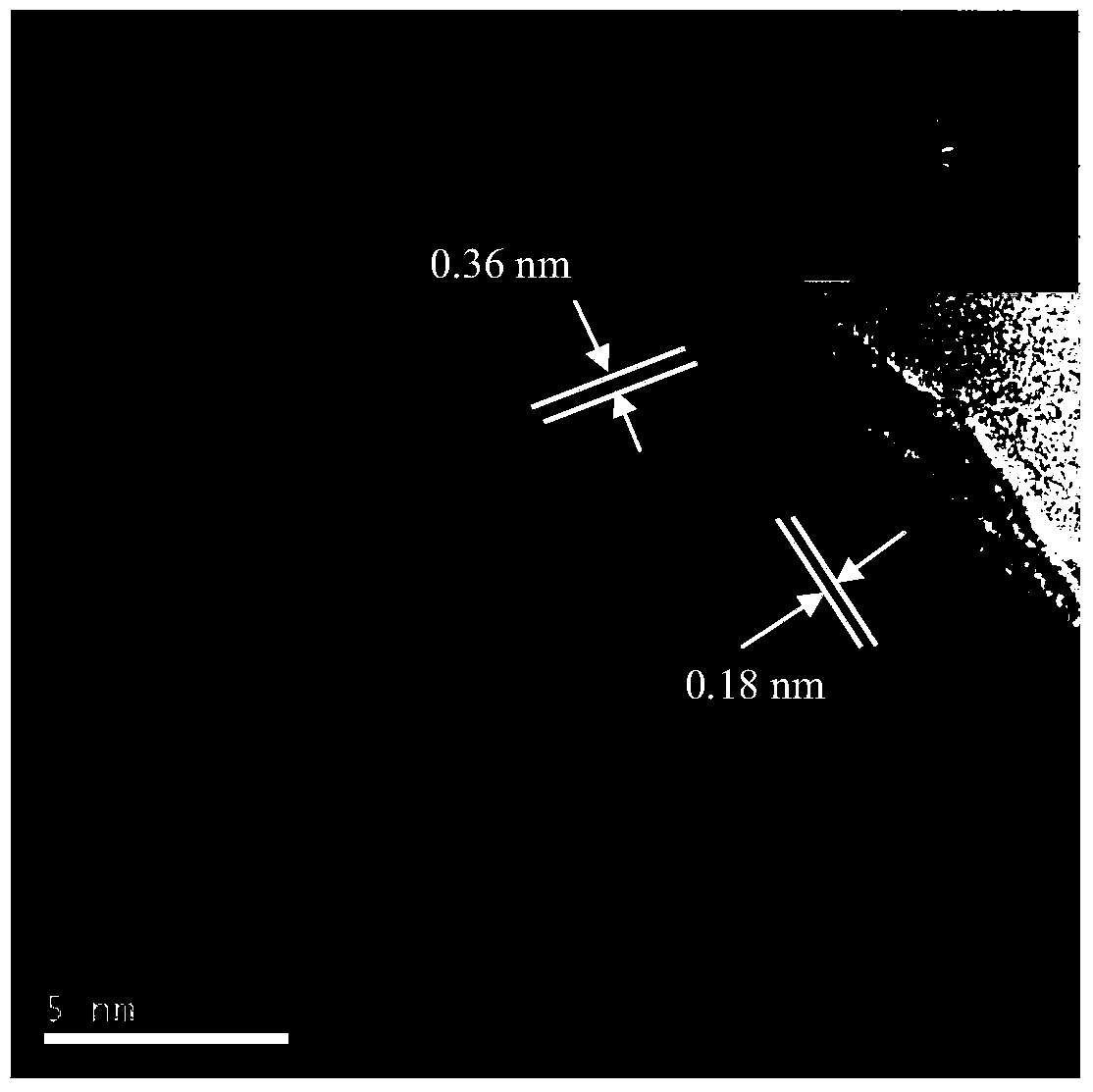

[0034] Take by weighing 2.5mmol of copper nitrate (Cu(NO 3 ) 2 ·3H 2 O), 5.0mmol malic acid was dissolved in 20mL distilled water, and magnetically stirred for 3h. Dissolve 2.5 mmol of boric acid in 30 mL of deionized water, and then add this solution dropwise to the aforementioned reaction solution, and magnetically stir for 4 h. Then the mixed solution was dried in an oven at 140°C to obtain a brown gel, which was roasted at 900°C for 7 hours to obtain a dark green powder, which was washed with 0.21mol / L hydrochloric acid and deionized water at 80°C for 3-3 hours. 4 times, centrifuged, and the powder was dried at 80°C to obtain Cu 3 B 2 o 6 sample. After XRD detection, the results are attached figure 1 , the resulting Cu 3 B 2 o 6 It is a pure substance, corresponding PDF card number: 28-398; tested by HRTEM, as attached image 3 shown, indicating that the prepared Cu 3 B 2 o 6 a single crystal structure. After the UV-vis test, the UV-visible diffuse reflectan...

Embodiment 3

[0037] Take by weighing 2.5mmol of copper nitrate (Cu(NO 3 ) 2 ·3H 2 O), 7.5mmol glucose was dissolved in 20mL distilled water, and magnetically stirred for 3h. Dissolve 1.75 mmol of boric acid in 30 mL of deionized water, and then add this solution dropwise to the aforementioned reaction solution, and magnetically stir for 2 h. Then dry the mixture in an oven at 120°C to obtain a brown gel, which is then roasted at 850°C for 7 hours to obtain a dark green powder, which is washed with 0.4mol / L hydrochloric acid and deionized water at 80°C for 3-3 hours. 4 times, centrifuged, and the powder was dried at 60°C to obtain Cu 3 B 2 o 6 sample. As in Example 1, the resulting Cu 3 B 2 o 6 It is a pure substance and has a single crystal structure.

[0038] Take 40mg of Cu obtained above 3 B 2 o 6 Add 35mL methylene blue solution (35mg / L) to the powder, react under the conditions of 600nm visible light, 25°C, 1200rpm, take samples regularly and determine the concentration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com