Method for annealing large-size calcium fluoride crystal

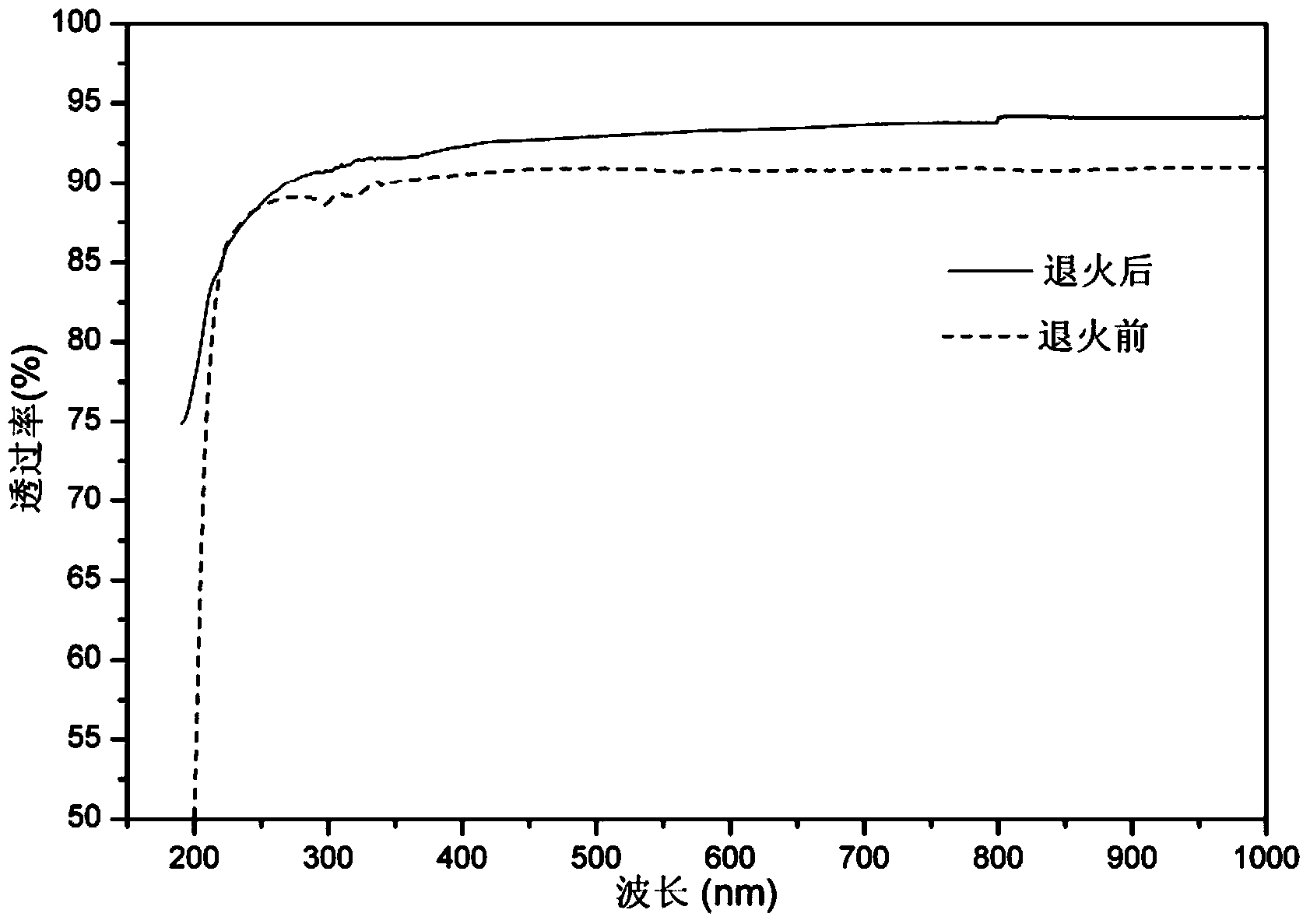

A calcium fluoride, large-size technology, which is applied in the field of annealing large-size calcium fluoride crystals, can solve problems such as crystal cracking, limited crystal growth size, and large thermal stress, so as to improve the laser damage threshold and facilitate thermal stress The effect of releasing and eliminating residual thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

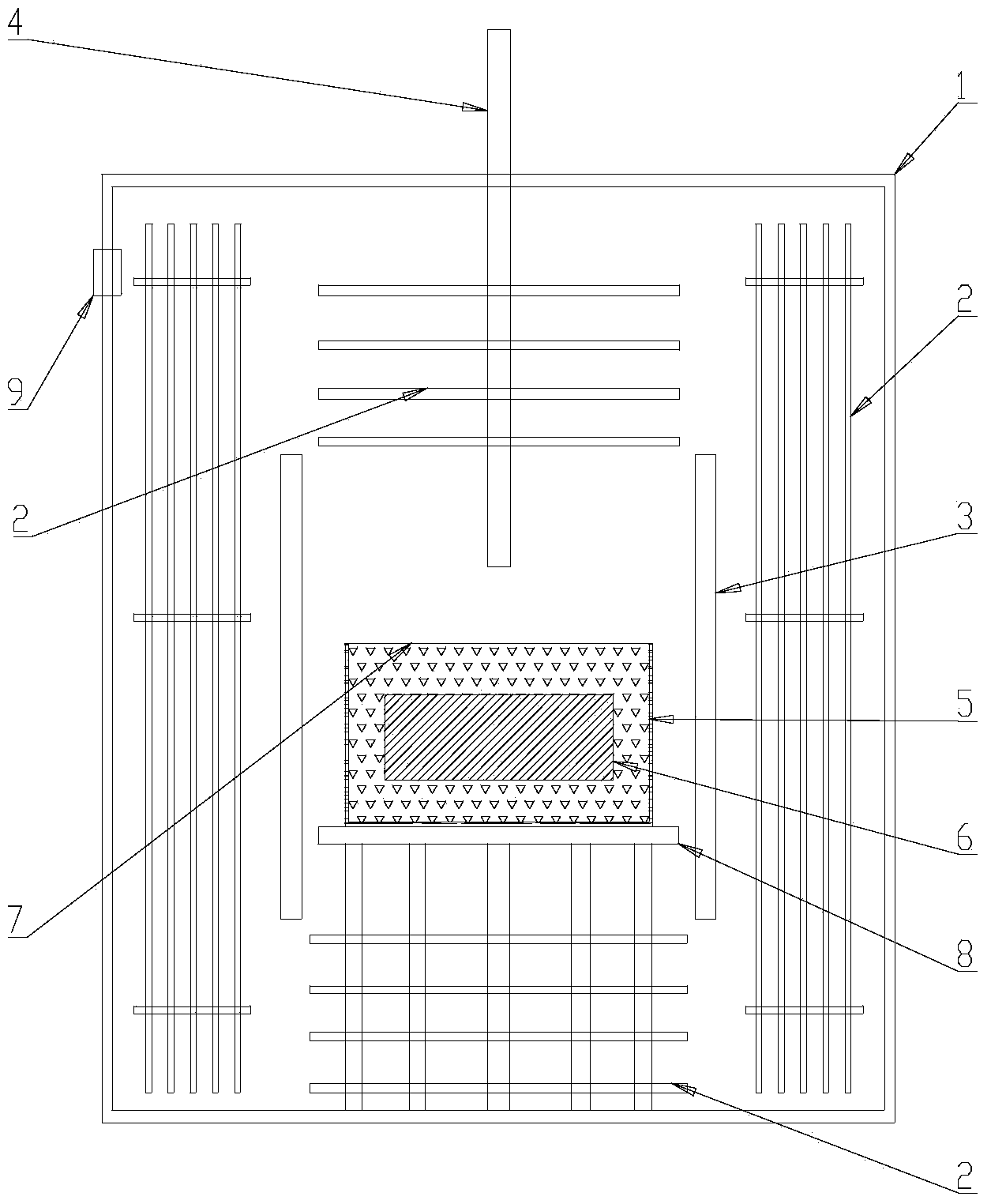

[0023] CaF grown by pulling method with a size of φ160mm×40mm 2 Put the crystal into a tungsten crucible, use high-purity CaF with a diameter of 2-5mm 2 Buried and covered with crushed crystals to avoid CaF 2 The crystal is in direct contact with the crucible wall and air; then placed in a high vacuum annealing furnace, when the vacuum degree is higher than 5×10 -3 Start to heat up at Pa for vacuum annealing: first raise the temperature to 950°C at a heating rate of 40°C / h, keep the temperature for 24 hours, then lower the temperature to 800°C at a cooling rate of 8°C / h, and then lower the temperature at a cooling rate of 15°C / h Cool down to room temperature, and finally remove the crystals.

Embodiment 2

[0025] CaF grown by pulling method with a size of φ160mm×40mm 2 Put the crystal into a graphite crucible, use high-purity CaF with a diameter of 2-5mm 2 Buried and covered with crushed crystals to avoid CaF 2 The crystal is in direct contact with the crucible wall and air; then placed in a high vacuum annealing furnace, when the vacuum degree is higher than 5×10 -3 When Pa is filled with a mixed gas of high-purity argon and carbon tetrafluoride, the volume fraction of carbon tetrafluoride is 5%, and the inflation pressure is 0.02Mpa; for atmosphere annealing: first, the temperature is raised at a heating rate of 30°C / h to 1000°C, keep the temperature constant for 30 hours, then drop to 850°C at a cooling rate of 6°C / h, then drop to room temperature at a cooling rate of 13°C / h, and finally take out the crystals.

Embodiment 3

[0027] CaF grown by the drop method with a size of φ200mm×60mm 2 Put the crystal into a tungsten crucible, use high-purity CaF with a diameter of 2-5mm 2 Buried and covered with crushed crystals to avoid CaF 2 The crystal is in direct contact with the crucible wall and air; then placed in a high vacuum annealing furnace, when the vacuum degree is higher than 5×10 -3 P a Start to heat up for vacuum annealing: first raise the temperature to 1030°C at a heating rate of 35°C / h, keep the temperature for 35 hours, then lower the temperature to 850°C at a cooling rate of 8°C / h, and then lower the temperature at a cooling rate of 15°C / h to room temperature, and finally remove the crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com