Industrial preparation method of high-protein grape seed dregs

A grape seed meal, high protein technology, applied in protein food processing, protein food ingredients, food science and other directions, can solve the problems of poor development of protein resources, low comprehensive utilization rate of grape seeds, limited processing technology, etc. Achieve the effect of alleviating high protein demand for feed, improving application value and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: The specific steps of the industrial production method of high-protein grape seed meal are as follows.

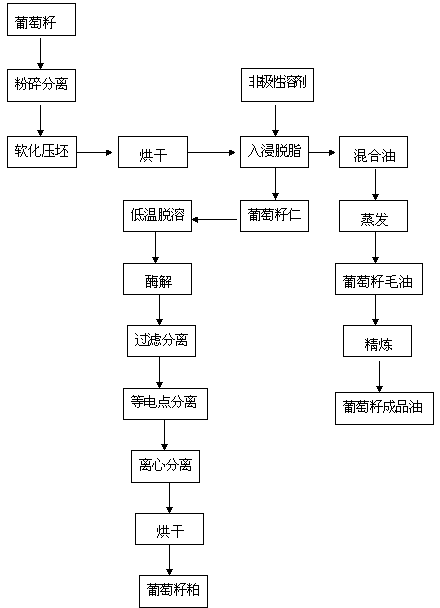

[0021] figure 1 As shown, the grape seeds are pulverized and separated from the kernels and shells by a grinder to obtain grape seed kernels. The grape seed kernels are softened and tempered with 55°C water for 45 minutes, and 7wt% of water is kept. Dried to a moisture content of 3wt%, sent to a degreasing extractor; using a non-polar solvent ethyl acetate to spray and extract in stages, the extraction temperature was 45 ° C, and the extraction time was 130 minutes to obtain a mixed oil; the degreased grape seeds were degreased at low temperature dissolve, remove the solvent, add a mixed aqueous solution of cellulase 80g / L, hemicellulase 65g / L and pectinase 60g / L according to the ratio of solid to liquid 1:2 (g / ml) for enzymolysis reaction, The reaction temperature is controlled at 30°C, and the reaction time is controlled at 1080min; after the enzymol...

Embodiment 2

[0022] Embodiment 2: The specific steps of the industrial production method of high-protein grape seed meal are as follows.

[0023] The grape seeds are crushed and separated from the kernels and shells by a pulverizer to obtain grape seed kernels. The grape seed kernels are softened and tempered with 58°C water for 50 minutes to keep 9wt% of moisture and enter the rolling mill for rolling, and then dried at 79°C until the moisture content is 3.5 wt%, and sent to the degreasing extractor; the non-polar solvent petroleum ether was sprayed and extracted in stages, the extraction temperature was 48°C, and the time was 130min to obtain a mixed oil; the degreased grape seeds were desolvated at low temperature, and the solvent was removed. Add a mixed aqueous solution of 90g / L cellulase, 60g / L hemicellulase and 90g / L pectinase according to the solid-liquid ratio of 1:3 (g / ml) for enzymolysis reaction, and the reaction temperature is controlled at 35°C. The reaction time is controlle...

Embodiment 3

[0024] Embodiment 3: The specific steps of the industrial production method of high-protein grape seed meal are as follows.

[0025] The grape seeds are crushed and separated from the kernel and shell by a pulverizer to obtain grape seed kernels. The grape seed kernels are softened and tempered with 57°C water for 45 minutes, and the moisture of 8wt% is kept. Then they are rolled into a rolling mill, and then dried at 60°C until the moisture content is 4wt%. , sent to the degreasing extractor; the non-polar solvent dichloromethane was used to spray and extract in stages, the extraction temperature was 48 ° C, and the extraction time was 160 min to obtain the mixed oil; Add a mixed aqueous solution of 100g / L cellulase, 90g / L hemicellulase and 80g / L pectinase at a liquid ratio of 1:3 to carry out the enzymolysis reaction. The reaction temperature is controlled at 32°C and the reaction time is controlled at 1250min; After the decomposition reaction, the material is filtered, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com