Catalyst for preparing 1,2-propylene glycol by glycerinum hydrogenation and preparation method thereof

A catalyst and hydrogen preparation technology, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem of high equipment investment costs, complex catalyst systems, and harsh reaction conditions and other issues, to achieve good industrial application prospects, low production costs, and short production cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Catalyst preparation: Weigh 9.44g copper nitrate, 1.91g potassium chloride, and 10g silicotungstic acid, respectively, and dissolve them in distilled water, immerse them in 41.5g aluminum oxide carrier, let stand for 5h, dry at 120℃, 400 After calcination at ℃ for 5 hours, a catalyst containing 5% copper, 2% potassium, 10% silicotungstic acid, and 83% aluminum oxide can be prepared.

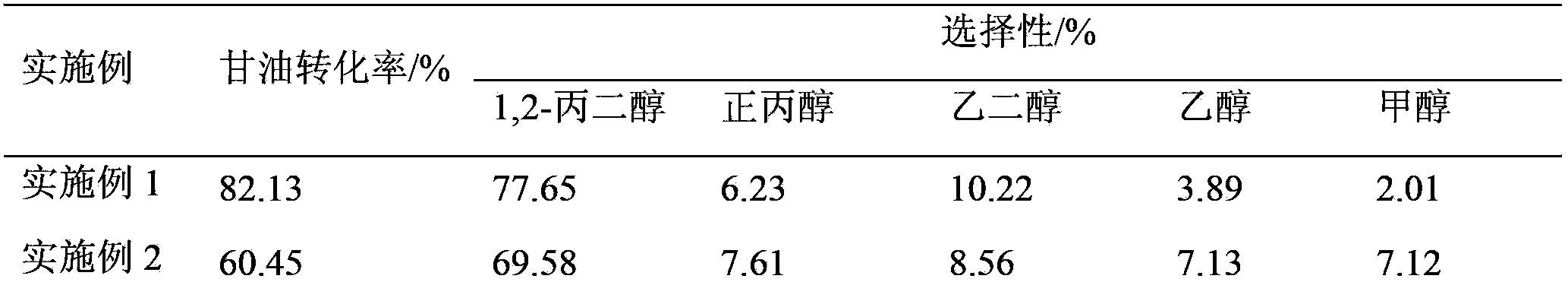

[0050] (2) The reaction is carried out in a continuous flow fixed-bed reactor: the catalyst loading is 10ml, the reaction pressure is 6MPa, the reaction temperature is 185℃, and the glycerol volumetric space velocity is 1.0h -1 , The hydrogen / glycerol molar ratio is 3:1, the reaction time is 10h, and the test results are shown in Table 1.

Embodiment 2

[0052] (1) Catalyst preparation: Weigh 17.32g of nickel nitrate, 7.28g of cobalt nitrate, and 7.5g of silicotungstic acid, respectively, and dissolve them in distilled water, immerse them on 37.5g of aluminum oxide carrier, stand for 5h, and dry at 120℃, 450 After calcination at ℃ for 5 hours, a catalyst containing 7% nickel, 3% cobalt, 15% silicotungstic acid, and 75% aluminum oxide can be prepared.

[0053] (2) The reaction is carried out in a continuous flow fixed-bed reactor: the catalyst loading is 10ml, the reaction pressure is 5MPa, the reaction temperature is 190℃, and the glycerol volumetric space velocity is 0.8h -1 , The hydrogen / glycerol molar ratio is 4:1, the reaction time is 15h, and the test results are shown in Table 1.

Embodiment 3

[0055] (1) Catalyst preparation: Weigh 22.88g zinc nitrate, 8.99g manganese chloride, and 7.5g phosphotungstic acid respectively, dissolve them in distilled water, immerse them on 35g silica carrier, let stand for 5h, dry at 120℃, 400℃ After calcination for 5 hours, a catalyst containing 10% zinc, 5% manganese, 15% phosphotungstic acid and 70% silica can be prepared.

[0056] (2) The reaction is carried out in a continuous flow fixed-bed reactor: the catalyst loading is 10ml, the reaction pressure is 5.5MPa, the reaction temperature is 195℃, and the volumetric space velocity of glycerol is 1.2h -1 , The hydrogen / glycerol molar ratio is 5:1, the reaction time is 20h, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com