Preparation method of porous graphene

A technology of porous graphene and graphene, applied in the field of materials engineering, can solve the problems of small pore size range of porous graphene, limit the subsequent application of new graphene-derived materials, complex process, etc., achieve a large pore size distribution range, suitable for large-scale The effect of industrial production and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

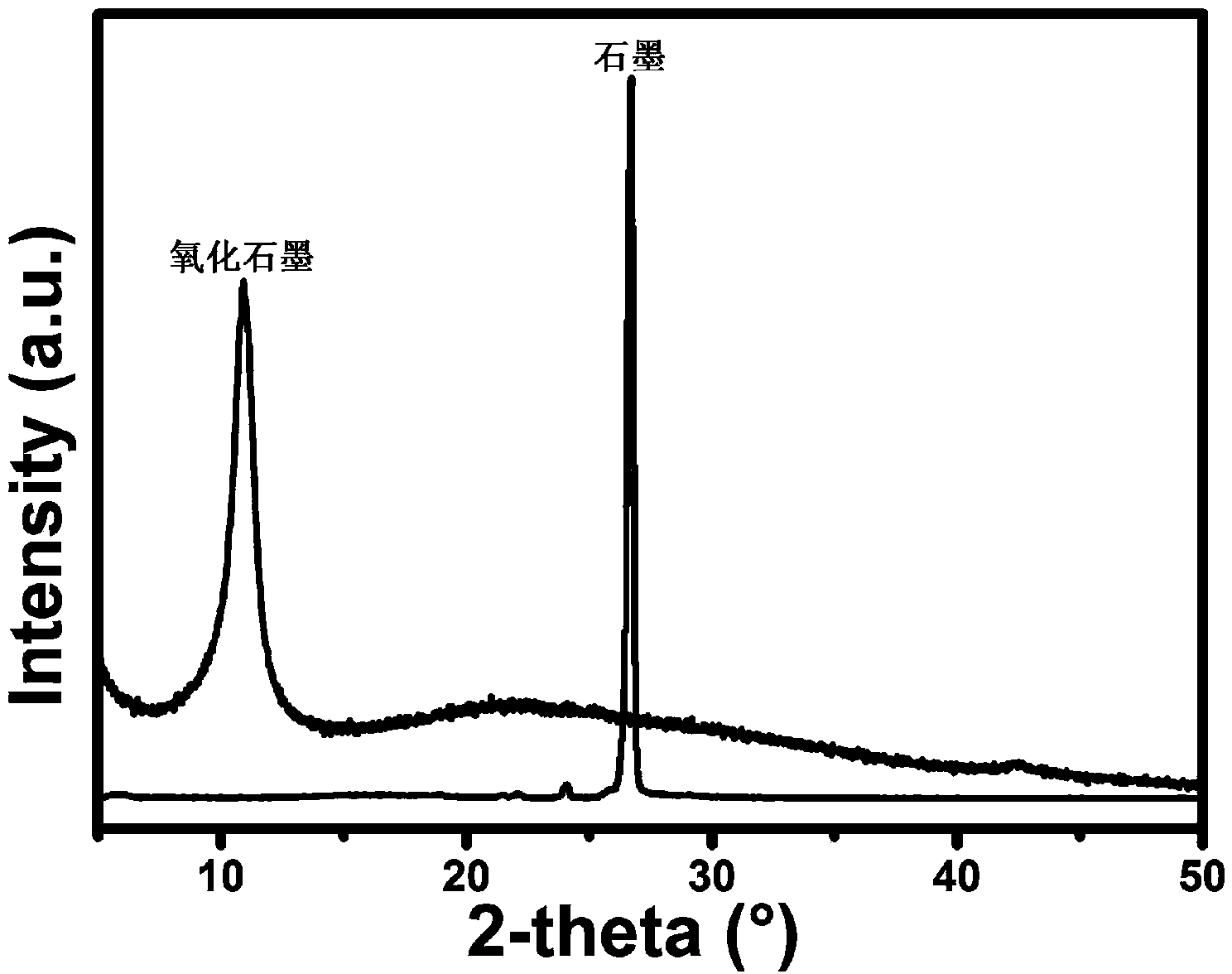

[0023] 1) Preparation of porous graphene oxide:

[0024] Take 0.02g of graphite oxide, prepare 100ml of a solution with a concentration of 0.2g / L, and ultrasonicate at a frequency of 20kHz for 30min to obtain a graphene oxide (GO) solution. Then the solution was centrifuged at 10,000rpm to collect the GO colloid at the bottom, mix the GO colloid with 200ml of nitric acid solution with a mass concentration of 70%, ultrasonicate at a frequency of 15kHz for 30min, then add deionized water, and repeatedly centrifuge and wash at the same speed. The system was washed to a pH of 4, and freeze-dried to obtain a porous graphene oxide solid with nanopores.

[0025] 2) Preparation of porous graphene:

[0026] Prepare the porous graphene oxide solid obtained in step 1 into 1 L of a solution with a mass concentration of 0.01 g / L, add 0.05 g of sodium borohydride to the graphene oxide solution, and react at a temperature of 100 ° C for 6 h to obtain a porous Graphene dispersion liquid, fi...

Embodiment 2

[0029] 1) Preparation of porous graphene oxide:

[0030] Take 0.015g of graphite oxide, prepare 1.5L of a solution with a concentration of 0.01g / L, and ultrasonicate at a frequency of 40kHz for 60min to obtain a graphene oxide (GO) solution. Then the solution was centrifuged at 12,000rpm to collect the GO colloid at the bottom, mixed with 15ml of 40% hydrofluoric acid solution, ultrasonicated at 28kHz for 60min, then deionized water was added, and centrifuged repeatedly at the same speed Washing, washing the system until the pH is 5, and freeze-drying to obtain a graphene oxide solid with nanopores.

[0031] 2) Preparation of porous graphene:

[0032] The porous graphene oxide solid obtained in step 1 is formulated into 20ml of a solution with a mass concentration of 0.5g / L, 0.2g of ascorbic acid is added to the graphene oxide solution, and the temperature is 80°C for 10 minutes to react to obtain porous graphite Graphene dispersion, filtered and washed, and freeze-dried to ...

Embodiment 3

[0034] 1) Preparation of porous graphene oxide:

[0035] Take 0.3g of graphite oxide, prepare 60ml of a solution with a concentration of 5g / L, and ultrasonicate at a frequency of 50kHz for 100min to obtain a graphene oxide (GO) solution. Then the solution was centrifuged at 15,000rpm to collect the GO colloid at the bottom, mix the GO colloid with 150ml of nitric acid solution with a mass concentration of 68%, ultrasonicate at a frequency of 60kHz for 120min, then add deionized water, and repeatedly centrifuge and wash at the same speed. The system was washed to a pH of 6, and freeze-dried to obtain a graphene oxide solid with nanopores.

[0036] 2) Preparation of porous graphene:

[0037] The porous graphene oxide solid obtained in step 1 is formulated into 50ml of a solution with a mass concentration of 5g / L, and 15ml of hydrazine hydrate aqueous solution containing 0.25g of hydrazine hydrate is added to the graphene oxide solution, and the temperature is 50°C for reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Hole size | aaaaa | aaaaa |

| Hole size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com