A-phase vanadium dioxide nanowire preparation method

A technology of vanadium dioxide nanometer and vanadium pentoxide, which is applied in the field of materials, can solve the problems of A-phase vanadium dioxide preparation operation difficulties, difficult control, and difficulty in obtaining nanowires, etc., and the synthesis method is simple, easy to operate, and easy to control , The effect of good crystallinity of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

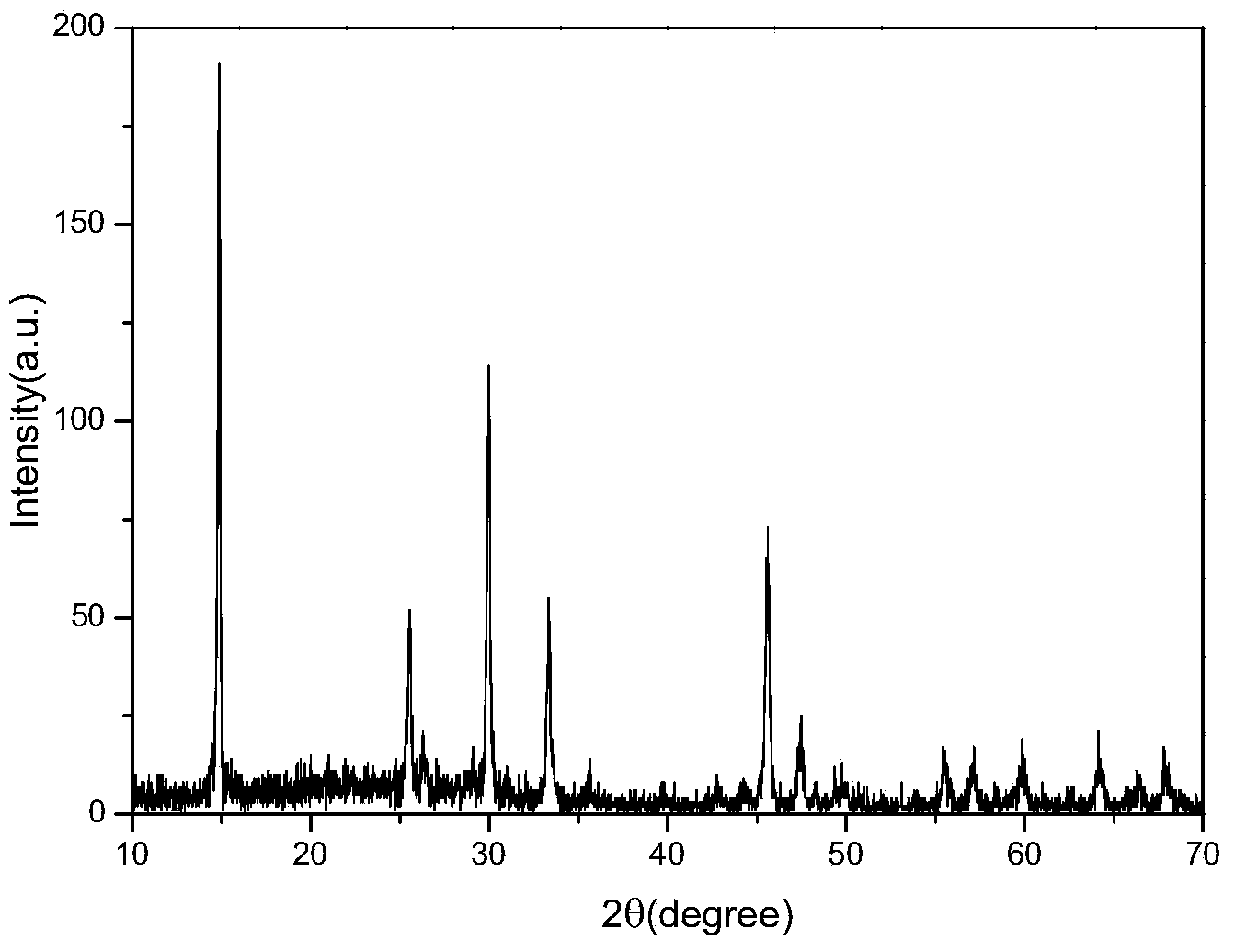

[0032] Accurately weigh 0.3g of vanadium pentoxide, 0.2g of oxalic acid and 0.1mL of polyethylene glycol 400 and disperse in 20mL of ultrapure aqueous solution, and vigorously stir at 60°C for 15 minutes at a stirring speed of 300rpm. Add the above solution into a 25mL polytetrafluoroethylene hydrothermal kettle with a filling ratio of 80%, raise the temperature to 240°C with a heating rate of 2.5°C / min, keep it warm for 60h, and finally cool down to room temperature naturally, pass through 1L of ultrapure water Wash with 200ml of alcohol, centrifuge and dry in an oven at 80°C for 8 hours to obtain the vanadium dioxide nanowires of phase A. Such as figure 1 For the measured XRD pattern, figure 2 It is a SEM topography picture. It can be seen that its length is 1-6 μm, its diameter is 20-300 nm, and its aspect ratio is 20:1-50:1.

Embodiment 2

[0034] Accurately weigh 0.3g of vanadium pentoxide, 0.2g of oxalic acid and 0.1mL of polyethylene glycol 600 and disperse in 20mL of ultrapure aqueous solution, and vigorously stir at 60°C for 15 minutes at a stirring speed of 300rpm. Add the above solution into a 25mL polytetrafluoroethylene hydrothermal kettle with a filling ratio of 80%, raise the temperature to 230°C with a heating rate of 2.5°C / min, keep it warm for 50h, and finally cool down to room temperature naturally, pass through 1L of ultrapure water After washing with 200ml alcohol, centrifuge and dry in an oven at 80°C for 8 hours to obtain phase A vanadium dioxide nanowires with a length of 1-10μm, a diameter of 20-400nm, and an aspect ratio of 25:1- 50:1.

Embodiment 3

[0036] Accurately weigh 0.3g of vanadium pentoxide, 0.2g of oxalic acid and 0.1g of polyethylene glycol 2000 and disperse in 20mL of ultrapure aqueous solution, and vigorously stir at 60°C for 15 minutes at a stirring speed of 300rpm. Add the above solution into a 25mL polytetrafluoroethylene hydrothermal kettle with a filling ratio of 80%, raise the temperature to 225°C at a heating rate of 2.5°C / min, keep it warm for 48h, and finally cool down to room temperature naturally, and pass through a large amount of 1L ultra-pure After washing with water and 200ml alcohol, centrifugal separation, and drying in an oven at 80° C. for 8 hours, the vanadium dioxide nanowires of phase A were obtained. Such as image 3 It is the measured SEM topography picture, its length is 5-30μm, diameter is 50-500nm, aspect ratio is 100:1-20:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com