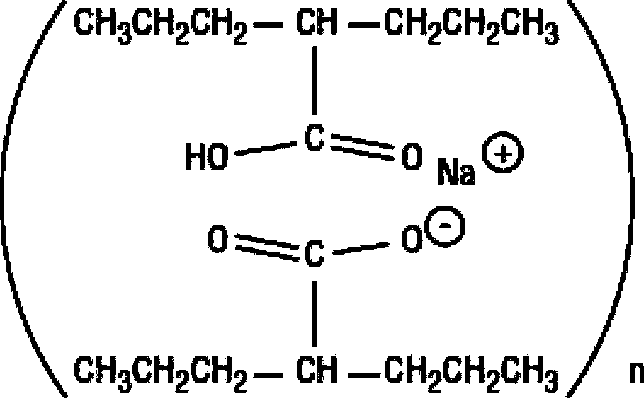

Recycling method of divalproex sodium crystallization mother liquor

A divalproex sodium and crystallization mother liquor technology, which is applied in chemical instruments and methods, carboxylate preparation, carboxylate preparation, etc., can solve the problems of low purity, difficult quality control, low recovery rate, etc., and achieve reduction The production cost, the reaction process is easy to control, and the effect of the method is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0052] A preferred embodiment of the present invention is:

[0053] A kind of recycling method of divalproex sodium crystallization mother liquor, it comprises:

[0054] 1) Concentrating divalproex sodium crystallization mother liquor to obtain a solid mixture containing divalproex sodium;

[0055] 2) adding the solid mixture obtained in step 1) to the sodium hydroxide solution to obtain a mixed solution;

[0056] 3) adding inorganic salts to the mixed solution obtained in step 2), and filtering to obtain metal salt precipitation of valproic acid; and

[0057] 4) Add the precipitated valproic acid salt obtained in step 3) into the hydrochloric acid solution, and fractionally distill the organic layer obtained after the reaction to obtain valproic acid.

[0058] Another preferred embodiment of the present invention is:

[0059] 1) Concentrate the divalproex sodium reaction mother liquor to dryness;

[0060] 2) Add 10-30% (w / v) concentration of sodium hydroxide until the mot...

Embodiment 1

[0071] In the three-necked flask, add divalproex sodium acetone reaction mother liquor 1700ml, recover acetone by normal pressure distillation, the distillation is complete at 60°C, and the concentrated residue weighs about 75 grams. Add about 39ml of 25% (w / v) sodium hydroxide solution, stir to adjust the pH to 8.0, the residue in the bottle is completely dissolved, add 20 grams of activated carbon, stir for 10 minutes and filter, add 27 grams of calcium chloride to the filtrate 54ml of aqueous solution was stirred to precipitate a large amount of white solids, cooled, suction filtered, washed with water, and dried to obtain 74.9 grams of white calcium valproate solids, with a yield of about 95% and a content of more than 99.1%.

[0072] Add the obtained calcium valproate into 200ml of 2mol / L hydrochloric acid, stir and separate the layers, distill the upper organic layer under reduced pressure, collect the distillate at 112-114℃ / 7~8mmHg, and obtain valproic acid transparent l...

Embodiment 2

[0074] In a three-neck flask, add divalproex sodium acetone reaction mother liquid 1700ml, recover acetone by atmospheric distillation, and the distillation is completed at 60°C, the concentrated residue weighs about 75 grams, and 25% (w / v) sodium hydroxide is added The solution is about 39ml, stir to adjust the pH to 9.5, all the residue in the bottle is dissolved, add 20 grams of activated carbon, stir for 10 minutes and filter, add 34ml of an aqueous solution made of 23 grams of magnesium chloride to the filtrate, stir to precipitate a large amount of white solid, cool, and suction filter, Washing with water and drying gave 71.6 grams of white magnesium valproate solid, with a yield of about 95.2% and a content greater than 99.1%.

[0075] Add the obtained magnesium valproate into 200ml of 2mol / L hydrochloric acid, stir and separate layers, distill the upper organic layer under reduced pressure, collect the distillate at 112-114°C / 7~8mm Hg, and obtain valproic acid transpare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com