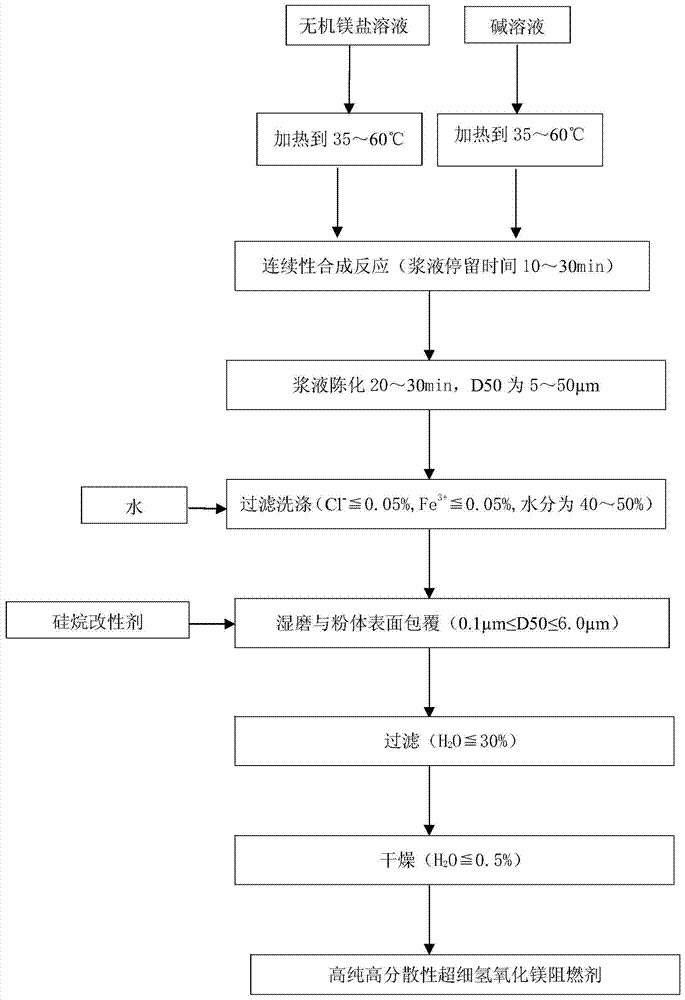

Method for integrally preparing high-dispersity ultrafine magnesium hydroxide flame retardant

A technology of ultra-fine magnesium hydroxide and magnesium hydroxide, applied in the direction of magnesium hydroxide, dyed organic silicon compound treatment, fibrous filler, etc., can solve the problems of complex process flow and high energy consumption, shorten the process flow and improve production Benefits, the effect of breaking through the technical problems of secondary coagulation and bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Prepare 4.5mol / L of MgCl 2 Solution 1000L and 9.0mol / L NH 3 ·H 2 O solution 1000L, respectively heated to about 35°C, the two solutions are simultaneously added to a closed reaction vessel with a stirring speed of 1500rpm through a metering pump at a feeding rate of 500ml / min, and the magnesium hydroxide synthetic slurry stays in the reaction vessel The time is about 10 minutes, the temperature during the residence process is 100° C., and the stirring speed is 1500 rpm. Transfer the magnesium hydroxide synthetic slurry into the aging device, and after aging for 20mim at 100°C, filter and wash the magnesium hydroxide synthetic slurry to make the water content about 50wt%, and the impurity Cl in the solid matter - ≦0.05wt%, Fe 3+ ≦0.05wt%, to get D50=5μm high-purity magnesium hydroxide wet cake.

Embodiment 2

[0031] Prepare 4.5mol / L of MgCl 2 Solution 1000L and 9.0mol / L NH 3 ·H 2 O solution 1000L, respectively heated to about 35°C, the two solutions are simultaneously added to a closed reaction vessel with a stirring speed of 500rpm through a metering pump at a feeding rate of 100ml / min, and the synthetic magnesium hydroxide slurry stays in the reaction vessel The time is about 20 minutes, the temperature during the residence process is 80° C., and the stirring speed is 500 rpm. Transfer the magnesium hydroxide synthetic slurry into the aging device, and after aging for 20mim at 80°C, filter and wash the magnesium hydroxide synthetic slurry to make the water content about 40wt%, and the impurity Cl in the solid matter - ≦0.05wt%, Fe 3+ ≦0.05wt%, to get D50=10μm high-purity magnesium hydroxide wet cake.

Embodiment 3

[0033] Prepare 0.5mol / L MgCl 2 Solution 1000L and 2.5mol / L NH 3 ·H 2 O solution 1000L, respectively heated to about 60°C, the two solutions are simultaneously added to a closed reaction vessel with a stirring speed of 50rpm through a metering pump at a feeding rate of 10ml / min, and the synthetic magnesium hydroxide slurry stays in the reaction vessel The time is about 30 minutes, the temperature during the residence process is 60°C, and the stirring speed is 50rmp. Transfer the magnesium hydroxide synthetic slurry into the aging device, and after aging for 30mim at 60°C, filter and wash the magnesium hydroxide synthetic slurry to make the water content about 40wt%, and the impurity Cl in the solid matter - ≦0.05wt%, Fe 3+ ≦0.05wt%, to get D50=50μm high-purity magnesium hydroxide wet cake.

[0034] Grinding and Surface Modification Magnesium Hydroxide

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com