Method for high value utilization of Fischer-Tropsch synthesis tail gas

A Fischer-Tropsch synthesis, high-value technology, applied in the preparation of liquid hydrocarbon mixtures, organic chemistry, lubricating compositions, etc., can solve the problems of high ethylene prices, achieve easy industrialization, increase product added value, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

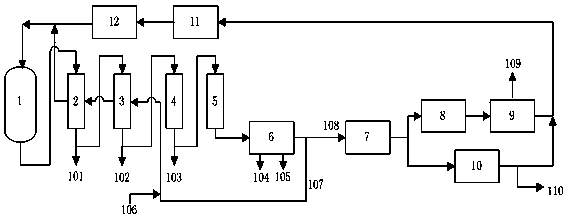

Image

Examples

Embodiment 1

[0034] Fischer-Tropsch reactor 1 adopts a tubular fixed-bed reactor. The inner diameter of the reactor shell is 200mm, the reactor tube length is 12m, and the tube diameter is Ф38x3mm. There are 7 tubes in total, arranged in an equilateral triangle, and the tube center distance is 48mm. The lower end of the reaction tube is equipped with a plugging spring, and the catalyst of each reaction tube can be discharged separately. The bottom of the bed is filled with Ф6mm ceramic balls for about 200mm, the top of the bed is filled with Ф6mm ceramic balls for about 200mm, the catalyst filling height is 11m, and the loading capacity is about 60L.

[0035] The catalyst is Co / ZrO 2 Catalyst, the catalyst is cylindrical after molding, d=4mm, h=5mm, density 0.87x10 3 Kg / m 3 , the porosity is about 0.3. The catalyst is prepared according to Chinese patent CN1398669: Co(NO 3 ) 2 ·6H 2 O, ZrOCl 2 and Mn(NO 3 ) 2 The mixed solution, the preparation concentration is 0.2M Na 2 CO 3 Sol...

Embodiment 2

[0046] Fischer-Tropsch reactor 1 adopts a slurry bed reactor, the inner diameter of the reactor shell is 1m, and the reactor volume is 1.2m 3 , the catalyst loading is about 25L, and the density is 0.8x10 3 Kg / m 3 . Catalyst selects Fe / Mn / Ca / K (100 / 50 / 11 / 4.5) catalyst, prepares according to the method described in patent CN1463794: Weigh Fe(NO 3 ) 3 9H 2 O194.07g, Ca(NO 3 ) 4 4H 2 O12.5g and concentration of 50% Mn(NO 3 ) 2 85.99g of the solution was prepared with deionized water to make a mixed solution with a total concentration of 0.3mol / L, and heated in a water bath at 50°C; a 0.5mol / L ammonia solution was prepared, added to the salt solution, stirred and precipitated, and allowed to stand for 12 hours. Suction filtration, washing and drying. Grind the dried filter cake finely, impregnate it with 16ml of potassium carbonate with a concentration of 0.91mol / L for 3h, dry it; then roast it at 500°C for 5h to obtain the final catalyst.

[0047] 48Nm from purificatio...

Embodiment 3

[0056] Fischer-Tropsch reactor 1 adopts a fixed fluidized bed reactor with a main pipe diameter of 0.5m and a height of 10m. The catalyst loading is about 50L and the density is 1.0x10 3 Kg / m 3 .

[0057] The catalyst is 16.8Co 3 o 4 / 0.2RuO 2 / Al 2 o 3 Catalyst, prepare catalyst according to the method described in Chinese patent CN102962066A: prepare a certain amount of 1mol / L aluminum sulfate aqueous solution, drop into 10mlNaOH, keep the water bath temperature as 40 ℃, hold time 180min, account for 0.2 (wt) of final catalyst by ruthenium oxide % Weighing RuCl 3 ·3H 2 O was added to the solution, peptizer H was added 2 SO 4 , stirred and refluxed at a microwave power of 50W until a transparent sol was maintained for 6h, and then aged at room temperature for 24h to obtain a gel. After drying at 50°C for 2 hours, place it in a microwave oven, heat up to 550°C for 12 hours at 2°C / min, and bake for 12 hours to prepare a catalyst carrier. Weigh Co(NO 3 ) 2 ·6H 2 O,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com