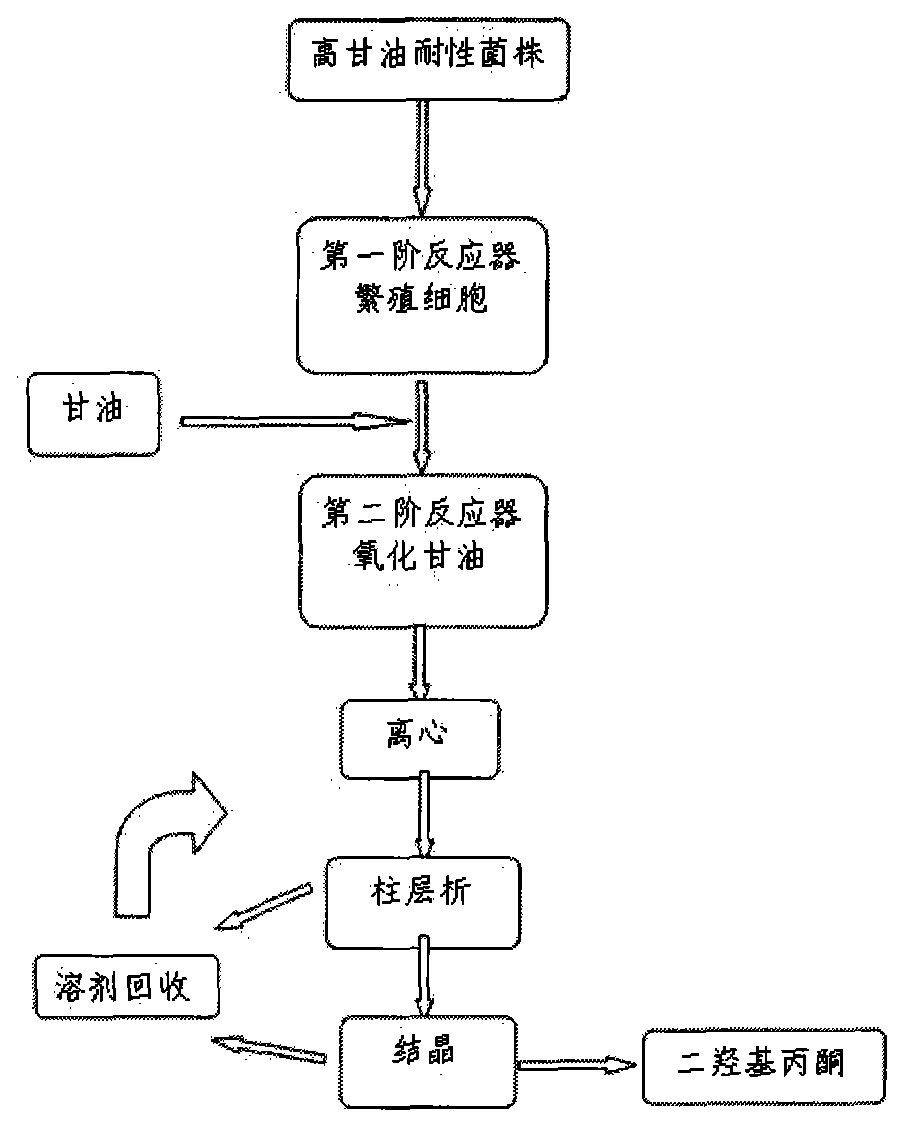

Method for producing dihydroxyacetone by converting glycerin by virtue of biological fermentation process

A technology of living dihydroxyacetone and biological fermentation method, which is applied in the biological field, can solve the problems of low glycerol concentration resistance of bacteria strains, bacterium cracking and inactivation process, and low product recovery rate, so as to increase product yield and improve the utilization of bacteria The effect of efficiency and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Inoculate high glycerol tolerance Portuguese Corynespora lusitaniae (Clavispora lusitaniae) bacterial strain G10 in the first stage reactor that adds sterilized fermentation medium, and fermentation medium is: yeast powder: 1%, peptone: 3%, ( NH 4 ) 2 SO 4 : 0.3%, NH 2 PO 4 : 0.05%, MgSO 4 : 0.01%, CaCO 3 : 0.05%, prepared with distilled water, adjusted the pH value to 7.0 with NaOH solution, and sterilized at 120°C and under high pressure.

[0021] (2) Add 5% sodium alginate solution and 2% CaCl to the bacterial suspension in the first-stage reactor 2 The solution is mixed evenly and flowed into the second-stage reactor, the temperature is 30-35°C, the rotation speed is 300r / min, the ventilation rate is 2vvm, and the pH value is about 5.0. Glycerin is fed at a speed of 15L / h for biocatalytic reaction. A pressure sensor is added to the outlet of the reactor, and when the glycerol concentration reaches 400g / L, the reaction liquid will flow out automatically. ...

Embodiment 2

[0025] (1) Inoculate high glycerol tolerance Portuguese Corynespora lusitaniae (Clavispora lusitaniae) bacterial strain G10 in the first stage reactor that adds sterilized fermentation medium, fermentation medium is: yeast powder: 4%, peptone: 1%, ( NH 4 ) 2 SO 4 : 0.1%, NH 2 PO 4 : 0.02%, MgSO 4 : 0.05%, CaCO 3 : 0.05%, prepared with distilled water, adjusted the pH value to 5.0 with NaOH solution, and sterilized at 120°C and autoclaved.

[0026] (2) Mix the bacterial suspension in the first stage reactor with 8% sodium alginate solution and 2% CaCl 2 The solutions are mixed and flowed into the second-stage reactor at a temperature of 30-35°C, a rotation speed of 300r / min, a ventilation rate of 2vvm, and a pH value of about 5.0. Glycerol is fed at a rate of 20L / h for biocatalytic reaction. In the second-stage reaction A pressure sensor is added to the outlet of the device, and when the concentration of glycerin reaches 400g / L, the reaction liquid will flow out automati...

Embodiment 3

[0030](1) Inoculate high glycerol tolerance Portuguese Corynespora lusitaniae (Clavispora lusitaniae) bacterial strain G10 in the first stage reactor that adds sterilized fermentation medium, and fermentation medium is: yeast powder: 6%, peptone: 4%, ( NH 4 ) 2 SO 4 : 0.1%, NH 2 PO 4 : 0.02%, MgSO 4 : 0.05%, CaCO 3 : 0.03%, prepared with distilled water, adjusted the pH value to 4.0 with NaOH solution, and sterilized at 120°C and under high pressure.

[0031] (2) Mix the bacterial suspension in the first-stage reactor with 10% sodium alginate solution and 4% CaCl 2 The solutions are mixed and flowed into the second-stage reactor at a temperature of 30-35°C, a rotational speed of 400r / min, a ventilation rate of 2vvm, and a pH value of about 5.0. Glycerin is fed at a rate of 25L / h for biocatalytic reaction. In the second-stage reaction A pressure sensor is added to the outlet of the device, and when the concentration of glycerin reaches 400g / L, the reaction liquid will fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com