Method for manufacturing black silicon materials

A black silicon and silicon substrate technology, applied in the field of photoelectric sensitive materials, can solve the problems of poor thermodynamic performance and crystal quality, limited application, high price, etc., and achieve a wide range of absorption wavelengths, huge application potential, and high absorption rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

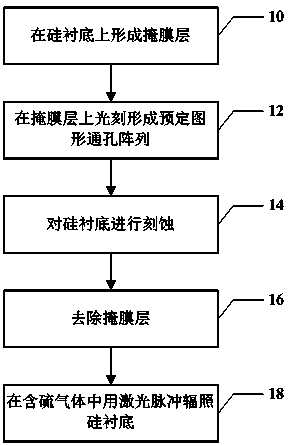

[0021] The specific steps of the method for manufacturing black silicon material according to the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0022] Such as figure 1 As shown, in the embodiment of the present invention, a method for manufacturing black silicon material includes step 10 , step 12 , step 14 , step 16 and step 18 . Each step will be described in detail below in conjunction with specific embodiments.

[0023] Step 10: forming a mask layer on the silicon substrate.

[0024] In an embodiment of the present invention, firstly a mask layer is formed on a silicon substrate.

[0025] In an embodiment of the present invention, the mask layer here may be a silicon nitride mask layer or a silicon oxide mask layer, and its thickness may be 90 to 600 nanometers. The silicon nitride mask layer or the silicon oxide mask layer can be formed on the silicon substrate by a deposition method, such as plasma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com