Waterborne polyurethane adhesive with high solid content and preparation method thereof

A water-based polyurethane, high solid content technology, applied in the field of polyurethane, can solve the problems of poor heat resistance, low initial tack, increased cost, etc., and achieve the effect of improving processing performance, high solid content, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

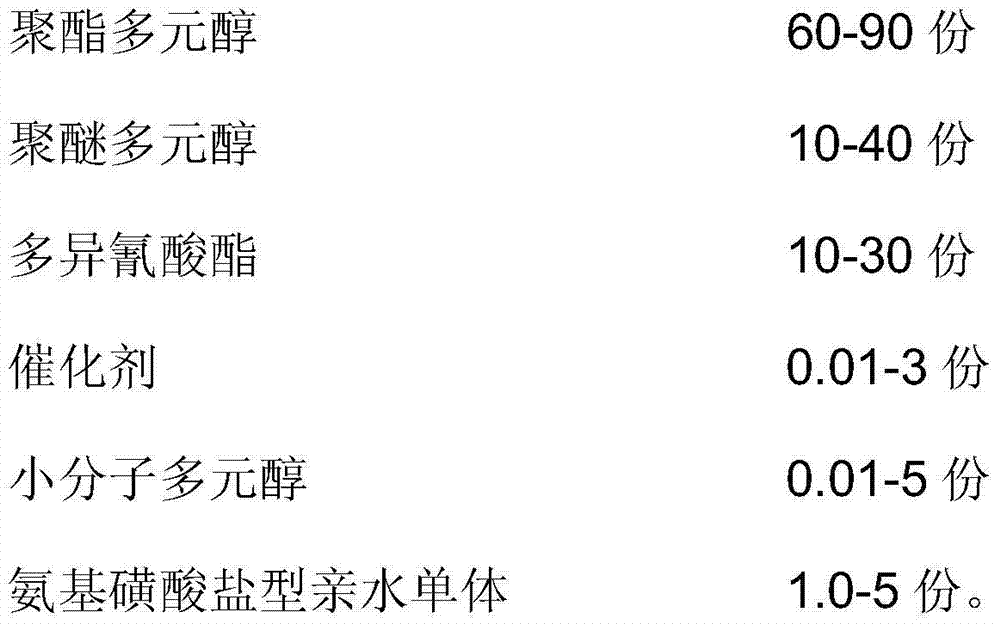

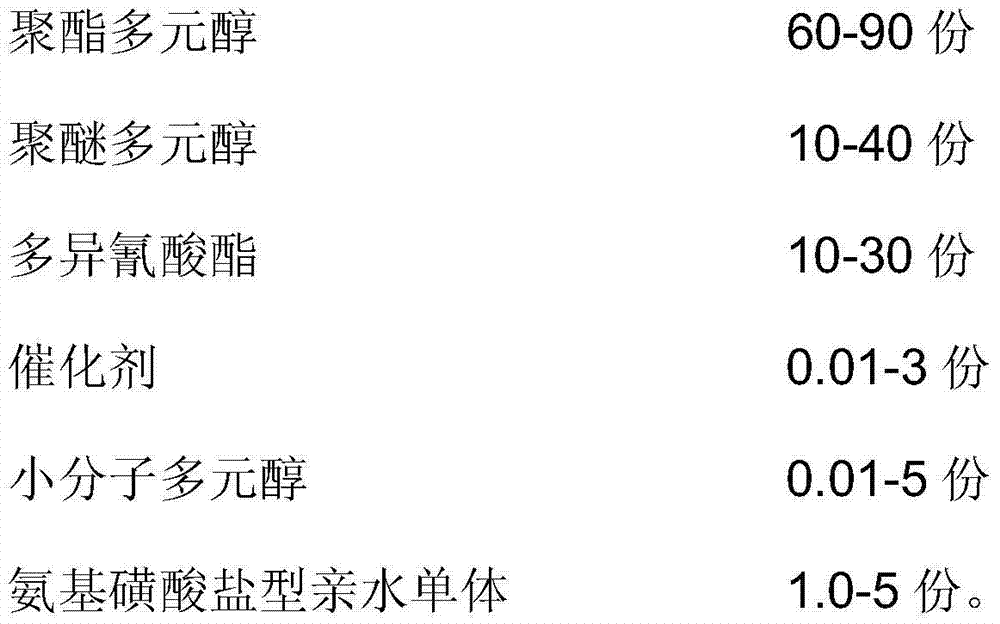

Method used

Image

Examples

Embodiment 1

[0026] Under a nitrogen atmosphere, 60 parts of poly-1,4-butylene adipate (molecular weight 3000), 40 parts of polyoxypropylene glycol (molecular weight 800), and 30 parts of hexamethylene diisocyanate were added to the reactor, 3 parts of 1,4-butanediol, after fully stirring, add 0.05 parts of dibutyltin dilaurate, raise the temperature to 75°C and stir for 5 hours. Then lower the temperature to 50°C, add an appropriate amount of acetone to reduce the viscosity, then add 2 parts of sodium N-(2-aminoethyl)-aminobutanesulfonate, and stir for 0.5h. Add deionized water under high-speed shearing to obtain a water-based polyurethane dispersion, and finally distill off acetone under reduced pressure to obtain a milky white water-based polyurethane emulsion with a slight blue light.

Embodiment 2

[0028] Under nitrogen atmosphere, 90 parts of poly-1,4-butylene adipate (molecular weight 2000), 20 parts of polyoxypropylene glycol (molecular weight 1000), 25 parts of isophorone diisocyanate, 3 parts of Add diethylene glycol into the reactor, stir well, add 0.05 parts of dibutyltin dilaurate, raise the temperature to 85°C and stir for 4 hours. Then lower the temperature to 50°C, add an appropriate amount of acetone to reduce the viscosity, then add 2 parts of sodium N-(2-aminoethyl)-aminobutanesulfonate, and stir for 0.5h. Add deionized water under high-speed shearing to obtain a water-based polyurethane dispersion, and finally distill off acetone under reduced pressure to obtain a milky white water-based polyurethane emulsion with a slight blue light.

Embodiment 3

[0030] Under a nitrogen atmosphere, add 80 parts of polypentylene adipate (molecular weight 3000), 20 parts of polyoxypropylene triol (molecular weight 1000), 25 parts of diphenylmethane diisocyanate, and 2 parts of ethylene glycol into the reactor , after fully stirring, add 0.08 parts of dibutyltin diacetate, raise the temperature to 90°C, and stir for 3.5 hours. Then lower the temperature to 50°C, add an appropriate amount of acetone to reduce the viscosity, then add 2 parts of sodium 1,2-dihydroxy-3-propanesulfonate, and stir for 0.5h. Add deionized water under high-speed shearing to obtain a water-based polyurethane dispersion, and finally distill off acetone under reduced pressure to obtain a milky white water-based polyurethane emulsion with a slight blue light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com