Mulberry nuts and preparation method thereof

A technology of mulberry and crisp fruit, applied in the field of mulberry crisp fruit and its preparation, can solve the problems of severe shrinkage, long drying time, uneven heating of materials, etc., and achieve the effect of crisp taste, rich mulberry fragrance and high retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

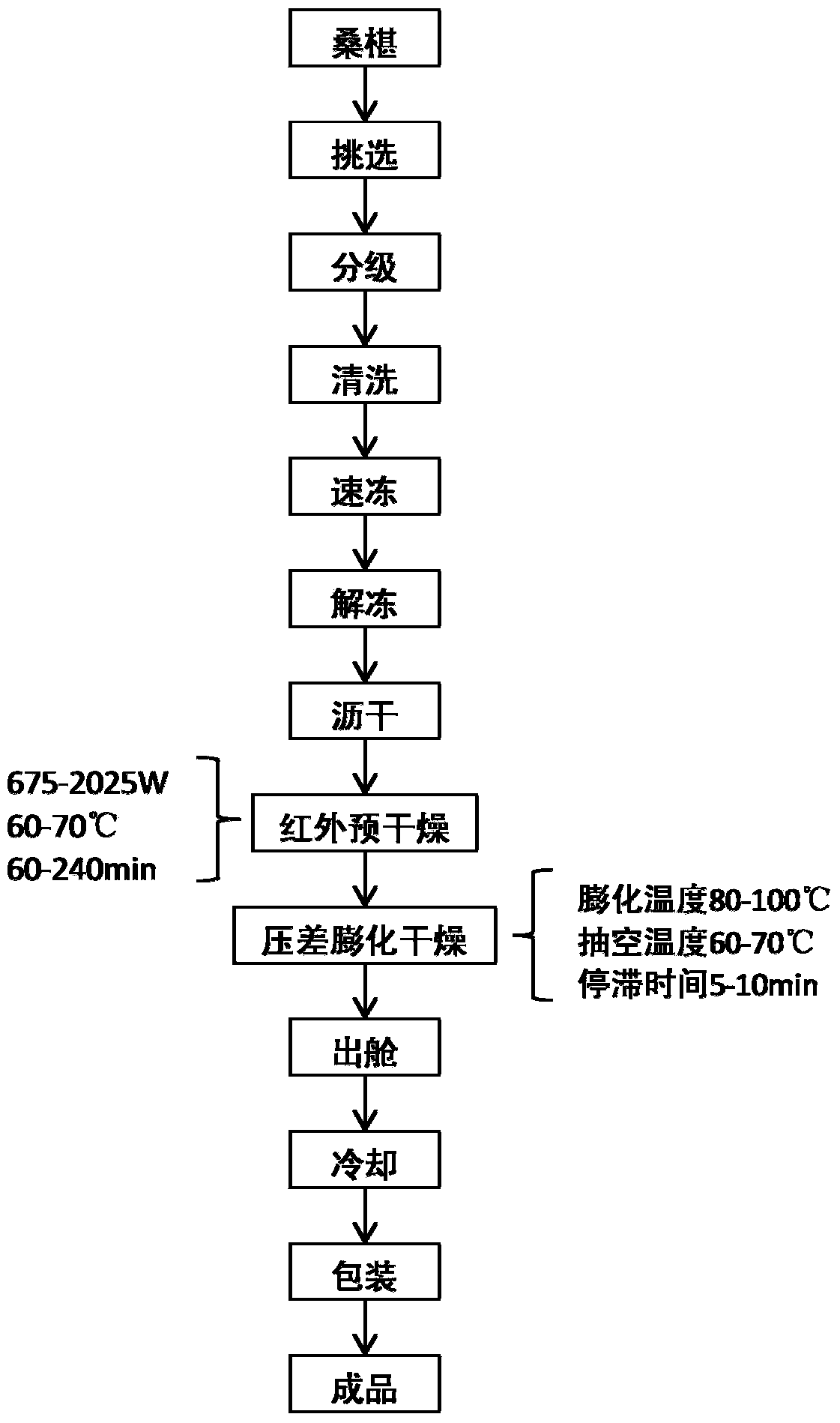

Method used

Image

Examples

preparation example Construction

[0037] Preparation of pH1.0 buffer solution: KCl aqueous solution with a concentration of 0.2mol / L: aqueous HCl solution with a concentration of 0.2mol / L=25:67 (V / V)

[0038] Preparation of pH4.5 buffer solution: NaAc aqueous solution with a concentration of 1mol / L: aqueous HCl solution with a concentration of 1mol / L: H 2 O=100:60:90 (V / V)

[0039]Determination of the sample to be tested: take 9mL of pH1.0 buffer solution and pH4.5 buffer solution, add 1mL of the test solution respectively, react at 40°C for 30min, and measure the absorbance at 510nm and 700nm respectively.

[0040] The absorbance A of the sample is calculated according to the following formula: A=(A 510 -A 700 ) pH1.0- (A 510 -A 700 ) pH4.5

[0041] Anthocyanin content (mg / L)=[(A×M w ) / (ε×1)]×Df×1000.

[0042] Among them, M w - Relative molecular mass of cyanidin glucoside (484.82mg / mol);

[0043] The molar extinction coefficient of ε-cyanidin glucoside (24825mol -1 );

[0044] Df - dilution fact...

Embodiment 1

[0049] The method for producing mulberries by utilizing medium-short-wave infrared combined pressure difference puffing and drying method provided by the present invention comprises the following steps:

[0050] (1) Selection, grading, and cleaning: Select complete, uninjured, and uniform-sized mulberries and wash them with water.

[0051] (2) Quick-freezing and thawing: Quick-freeze the raw materials for 8 hours at -40°C. Before processing, take the raw mulberries out of the freezer and thaw at room temperature.

[0052] (3) Drain: Drain the water on the surface of the mulberries and set aside.

[0053] (4) Primary drying: put the mulberries obtained in step (3) into a medium-short wave infrared drying equipment for pre-drying, the infrared lamp power is 675W, the drying temperature is 60°C, and the drying time is 240min, and the pre-dried mulberry ( Moisture content is 60-75%).

[0054] (5) Secondary drying: Put the pre-dried mulberry into the puffing equipment, adjust th...

Embodiment 2

[0066] The method provided by the present invention to produce mulberries by utilizing medium-short wave infrared combined with differential pressure puffing and drying method comprises the following steps:

[0067] (1) Selection, grading, and cleaning: Select complete, uninjured, and uniform-sized mulberries and wash them with water.

[0068] (2) Quick-freezing and thawing: Quick-freeze the raw materials for 8 hours at -40°C. Before processing, take the raw mulberries out of the freezer and thaw at room temperature.

[0069] (3) Drain: Drain the water on the surface of the mulberries and set aside.

[0070] (4) Primary drying: Put the mulberries obtained in step (3) into the medium and short wave infrared drying equipment for drying. The power of the infrared lamp is 2025W, the drying temperature is 80°C, and the drying time is 60min, and the pre-dried mulberries (moisture The content is 60-75%).

[0071] (5) Secondary drying: Put the pre-dried mulberry into the puffing eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com